Method for extracting multiple chemical products from coal-tar oil

A technology for chemical products and coal tar, which is applied in tar processing by distillation and tar removal by water, etc., can solve the problems of poor quality assurance of asphalt, low concentration of naphthalene, complicated production process, etc., and achieve high quality asphalt. Good, simple process, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

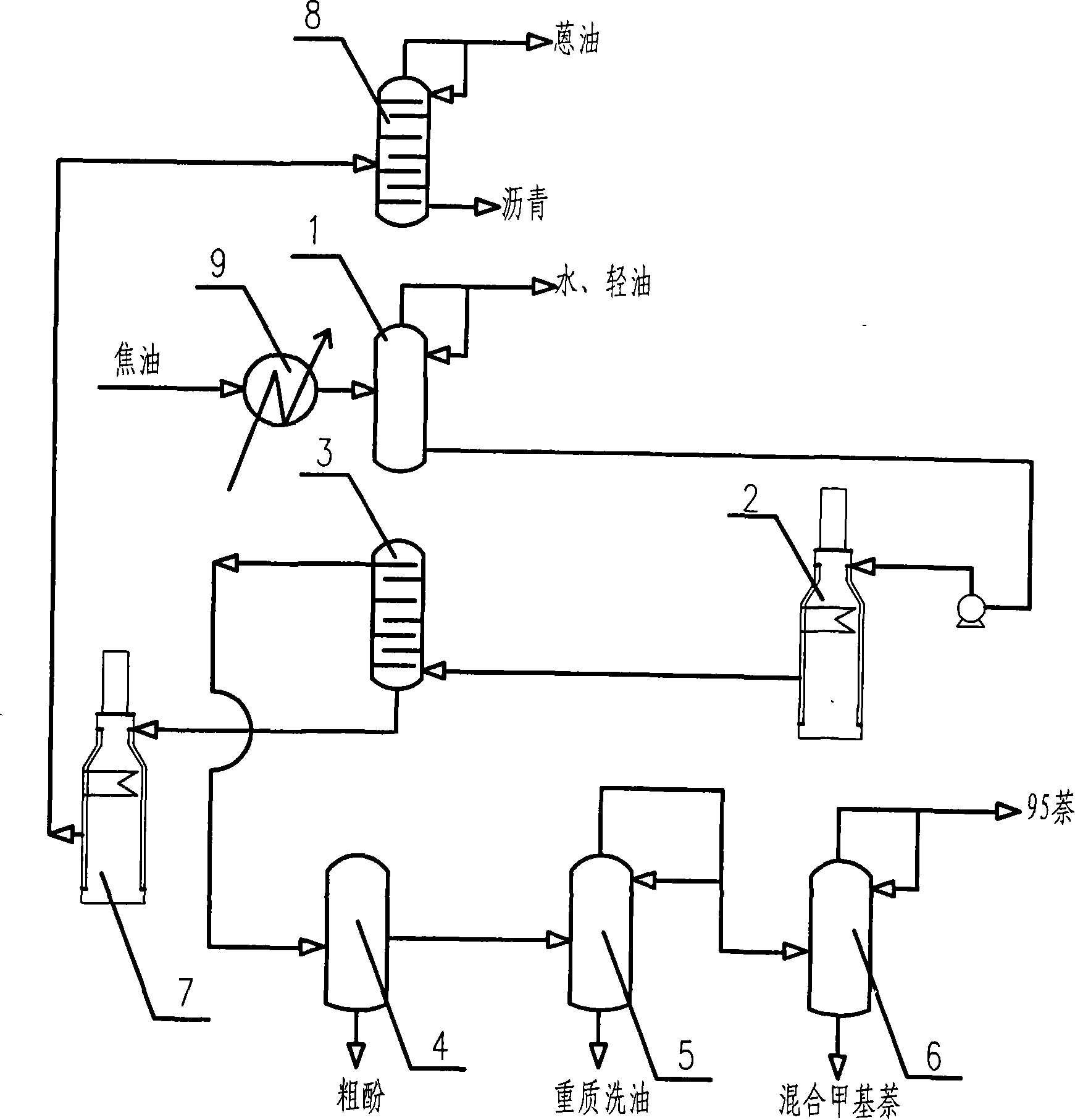

[0020] Referring to accompanying drawing, the present invention is carried out by following processing steps:

[0021] 1. Dehydration

[0022] Heat 100kg of coal tar to 120°C through the heat exchanger 9, enter the dehydration tower 1, and reflux it for a period of time. After the operation is stable, cut off the water and light oil on the top of the tower, and let it stand to separate the light oil product. The tar at the bottom of the tower is sent to the next process for processing.

[0023] 2. Initial distillation

[0024] The tar from which water and light oil have been removed is heated to 290°C by the tubular furnace 2 and then enters the distillation tower 3, and the triple-mixed fraction at 185°C-249°C is cut from the top of the tower and sent to the scrubber 4 for dephenolization, and the heavy oil distilled from the bottom of the tower The fraction enters the heating furnace 7 for heating, and the dephenolization of the three mixed fractions is washed with 30% sod...

Embodiment 2

[0035] Referring to accompanying drawing, the present invention is carried out by following processing steps:

[0036] 1. Dehydration

[0037] Heat 100kg of coal tar to 130°C through the heat exchanger 9, enter the dehydration tower 1, and reflux it for a period of time. After the operation is stable, cut off the water and light oil on the top of the tower, and let it stand to separate the light oil product. The tar at the bottom of the tower is sent to the next process for processing.

[0038] 2. Initial distillation

[0039] The tar from which water and light oil have been removed is heated to 300°C by the tube furnace 2 and then enters the distillation tower 3, and the triple-mixed fraction at 186°C-246°C is cut from the top of the tower and sent to the scrubber 4 for dephenolization, and the heavy oil distilled from the bottom of the tower The fraction enters the heating furnace 7 for heating, and the dephenolization of the three mixed fractions is washed with 15% sodium...

Embodiment 3

[0049] Referring to accompanying drawing, the present invention is carried out by following processing steps:

[0050] 1. Dehydration

[0051] Heat 100kg of coal tar to 125°C through the heat exchanger 9, enter the dehydration tower 1, and reflux it for a period of time. After the operation is stable, cut off the water and light oil at the top of the tower, and let it stand to separate the light oil product. The tar at the bottom of the tower is sent to the next process for processing.

[0052] 2. Initial distillation

[0053] The tar from which water and light oil have been removed is heated to 295°C by the tube furnace 2 and then enters the distillation tower 3, and the triple-mixed fraction at 187°C-247°C is cut from the top of the tower and sent to the scrubber 4 for dephenolization, and the heavy oil distilled from the bottom of the tower The fraction enters the heating furnace 7 for heating, and the dephenolization of the three mixed fractions is washed with 20% sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com