Microwave range using microwave as heating source

A microwave cooker and microwave technology, which is applied in the application expansion field of microwave absorbing materials, can solve the problems of inability to realize frying, frying, frying and other production methods, and achieve the effects of simple structure, safe use and reliable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

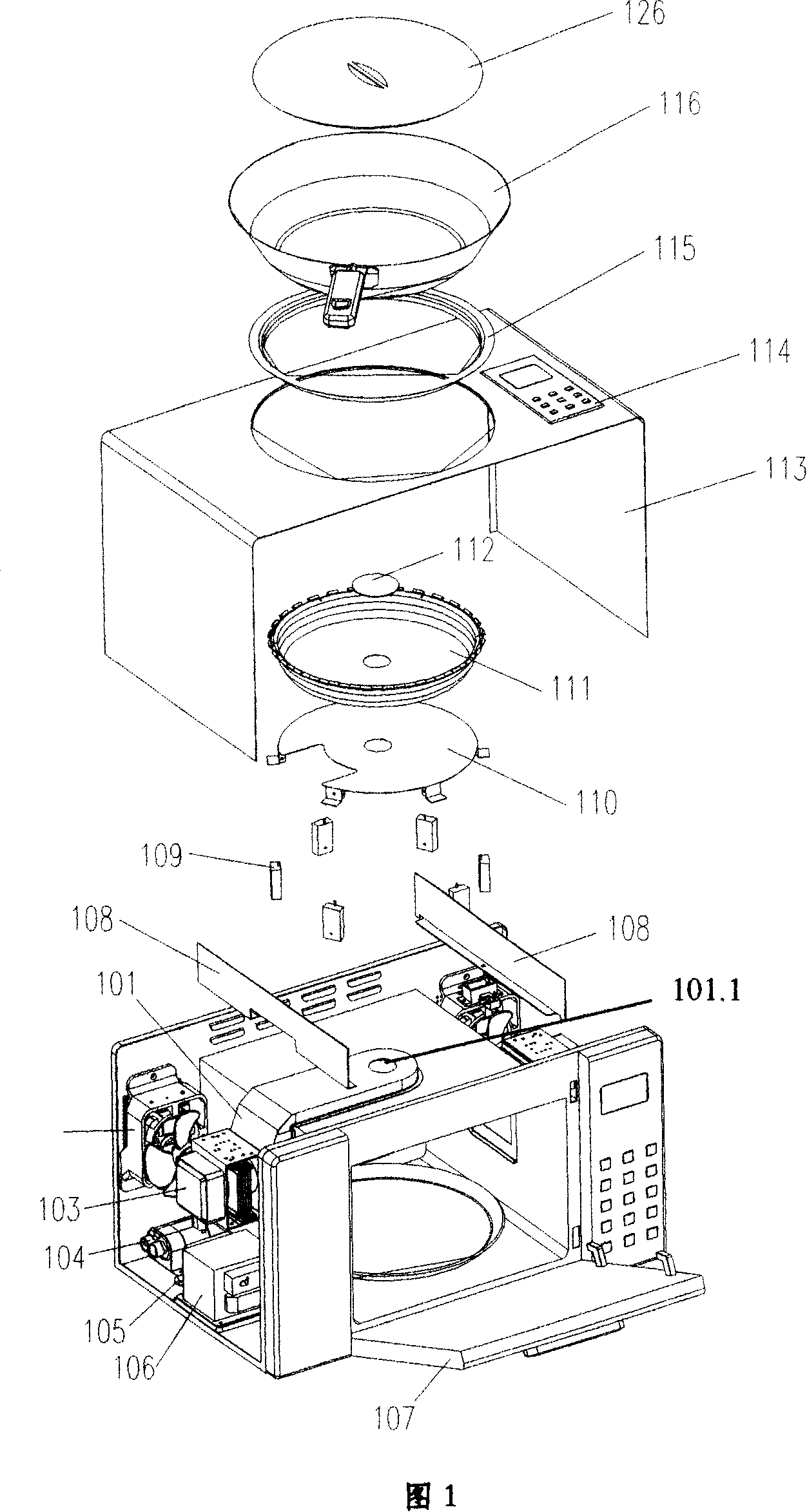

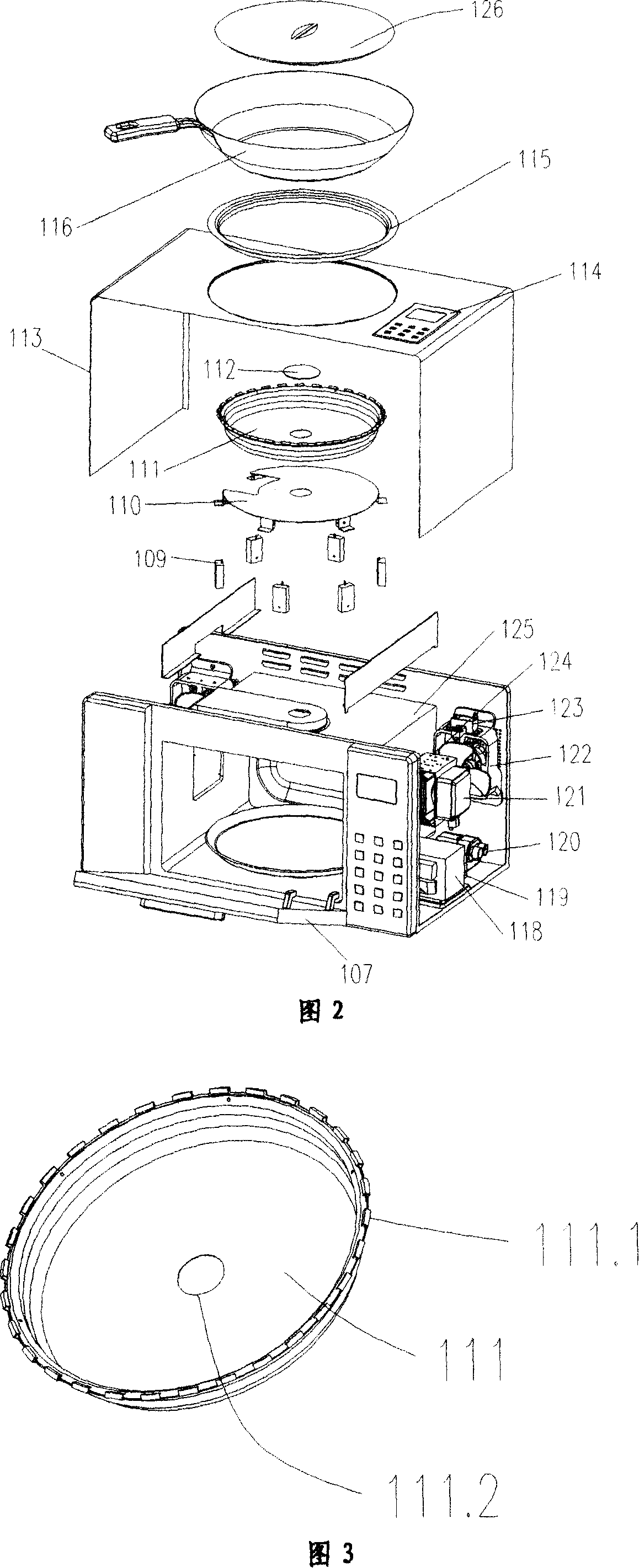

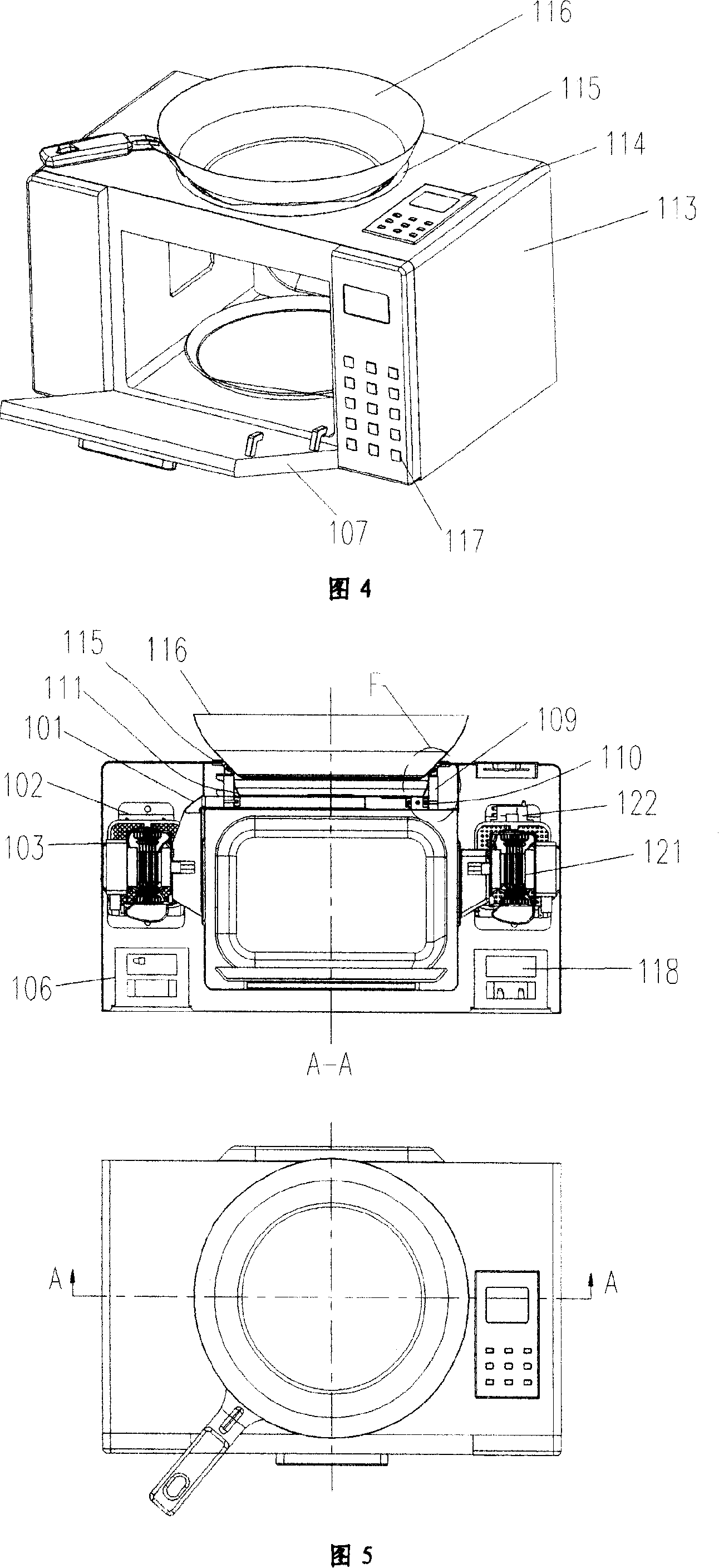

[0022] The basic structure of the patent of the present invention is shown in Figure 1 and Figure 2, including a control computer board 117, a transformer 118, a high voltage fuse 119, a high voltage capacitor 120, a magnetron 122, a furnace chamber waveguide assembly 124, a furnace chamber assembly 125, etc. A microwave direct heating system composed of a magnetron 103, a stove cavity component 111, a stove cavity waveguide component 101, a micro-touch control component bracket 110, a high-voltage capacitor 104, a high-voltage fuse 105, a transformer 106, A heating system composed of a micro-touch control assembly 109, a retaining ring 115, a microwave oven 116, a computer control unit 114, and a baffle 108. Wherein the baffle plate 108 is placed between the furnace cavity assembly 125 and the outer cover 113; the micro-touch control assembly 109 is placed on the micro-touch control assembly bracket 110, and the micro-touch control assembly bracket 110 is provided with the ins...

Embodiment 2

[0024] The basic structure of the patent of the present invention is the same as that of Embodiment 1, except that the microwave oven control computer board 114 and the microwave oven control computer board 117 are combined into one, and only one control computer board is used to control the microwave oven and the microwave oven. The control computer board can be placed at any one of the above-mentioned two control computer board positions.

Embodiment 3

[0026] The basic structure of the patent of the present invention is the same as that of Embodiment 1, except that the micro-touch control component bracket 110 is fixed on the cooking cavity waveguide component 101 or the cooking cavity component 111 or between the two.

[0027] Example 3:

[0028] The basic structure of the patent of the present invention is the same as that of Embodiment 1, except that the cooking cavity assembly 111 is placed directly above the cavity assembly 125, while the cooking cavity waveguide assembly 101 is placed above the cavity assembly 125 and on the side of the cooking cavity assembly 111 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com