Electrophotographic photosensitive body

A technology of electrophotography and photoreceptor, used in optics, electrography, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0213] Production Example 1 (Oil-encased melamine-formaldehyde resin microcapsules)

[0214]The pH of 100 g of a 5 mass % aqueous solution in which an ethylene-maleic anhydride copolymer (manufactured by モンサント ミカルズ, EMI-31), which is an anionic water-soluble polymer substance, was dissolved was adjusted to 4.5, and mineral oil was added to the solution. [ISOVG150, dynamic viscosity of center value 150mm 2 / s (40° C.)] 100 ml was used as a fluid, and was emulsified and dispersed with a homogenizer to obtain an O / W type emulsion with an oil droplet diameter of 2-3 μmm.

[0215] While stirring this emulsion system, 70 g of a solution of a methylol / melamine resin aqueous solution (manufactured by Sumitomo Chemical Co., Ltd., Spemire-Semi-Rejin 613) adjusted to a solid content of 17% by mass was added, and the temperature of the system was increased to At 55° C., stirring was continued for about 2 hours, and then 15% by mass of caustic soda aqueous solution was added to adjust the...

Embodiment 1

[0224] Using a polyethylene terephthalate resin film on which aluminum metal was vapor-deposited as a conductive substrate, a charge generating layer and a charge transporting layer were sequentially laminated on the surface thereof to manufacture an electrophotographic photoreceptor having a laminated photosensitive layer formed thereon.

[0225] 0.5 mass part of oxytitanium phthalocyanine was used as a charge generating substance, and 0.5 mass part of butyral resin was used as binder resin.

[0226] These were added to 19 parts by mass of dichloromethane as a solvent, dispersed with a ball mill, the dispersion was applied on the surface of the above-mentioned conductive base film with a bar coater, and dried to form a charge generating layer with a film thickness of about 0.5 μm. .

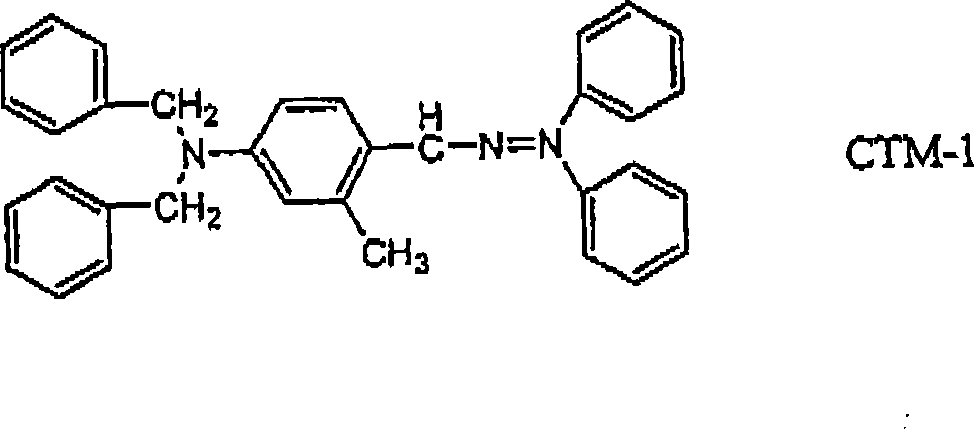

[0227] Next, 0.5 g of the compound (CTM-1) represented by the following structural formula as a charge transport material,

[0228]

[0229] and polycarbonate resin [PC-1: 1,1-bis(4-hydroxyp...

Embodiment 2

[0242] Except for replacing the polycarbonate resin (PC-1) of Example 1 with a polycarbonate resin [PC-2: 2,2-bis(3-methyl-4-hydroxyphenyl)propane polycarbonate, viscosity uniformity Except molecular weight=50000], a photoreceptor was produced in the same manner as in Example 1, and the dispersibility and electrophotographic properties were evaluated.

[0243] These results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com