Electric spark process discharging state forecasting method

A discharge state and prediction method technology, which is applied in the direction of electric processing equipment, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increased arc and short circuit state, low processing efficiency, poor processing quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

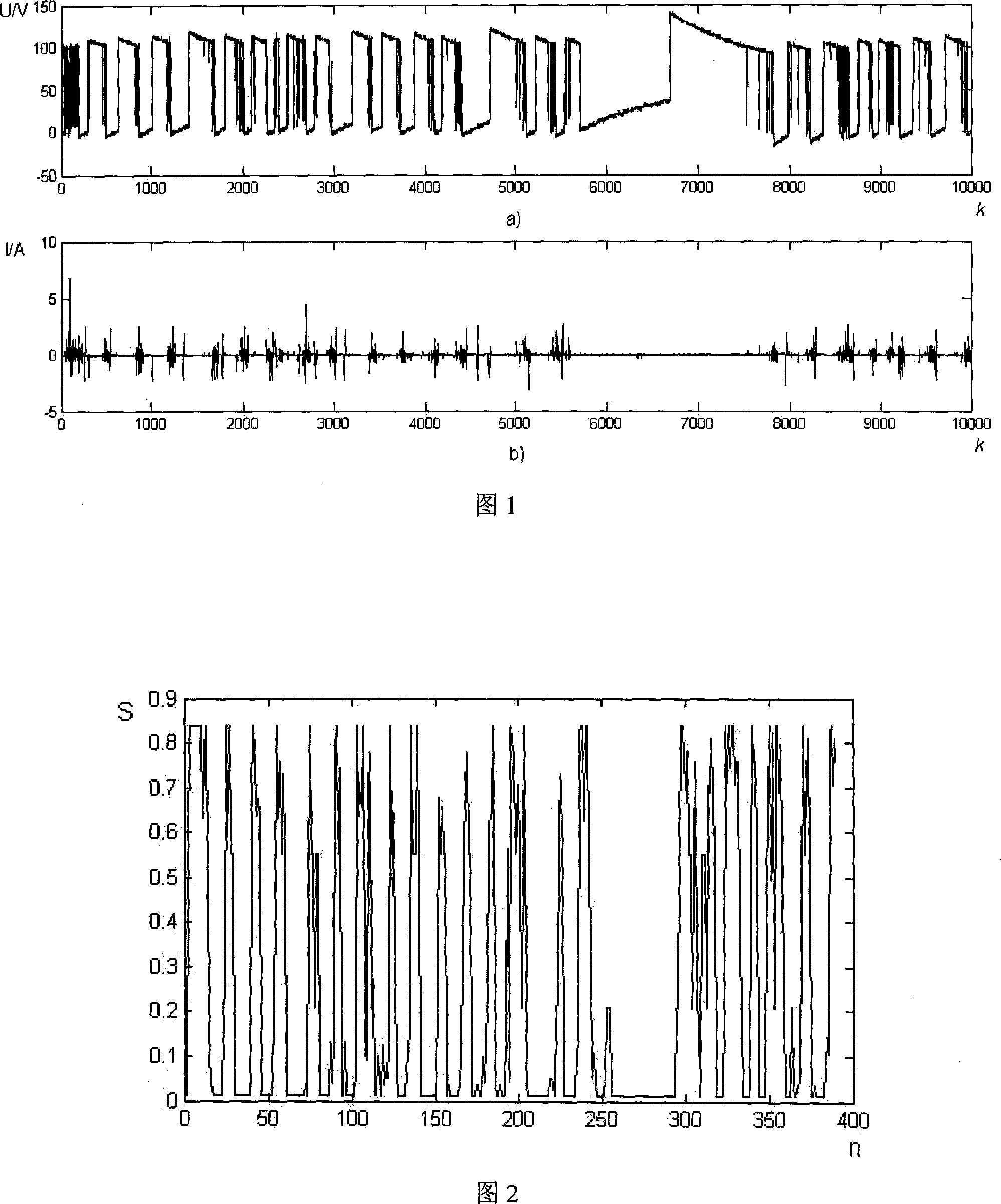

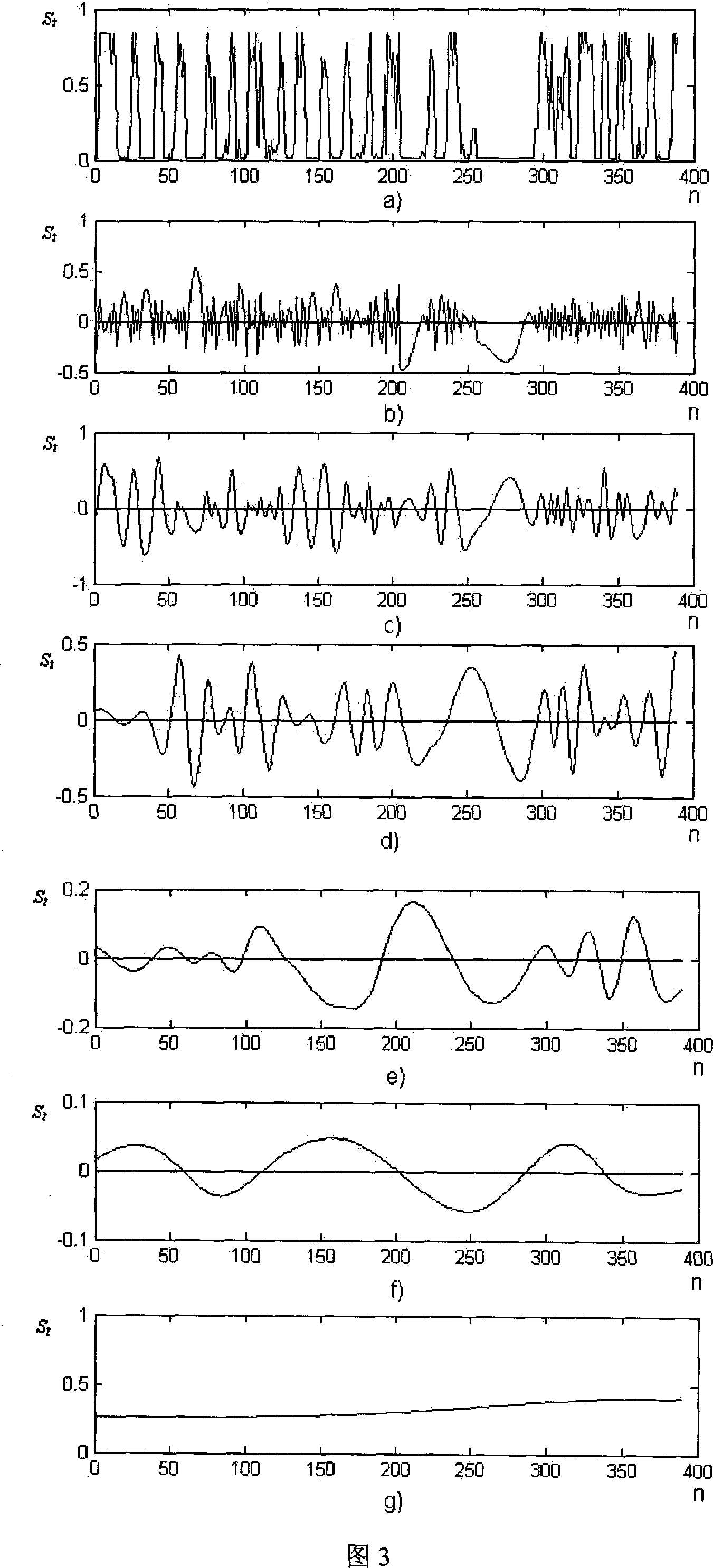

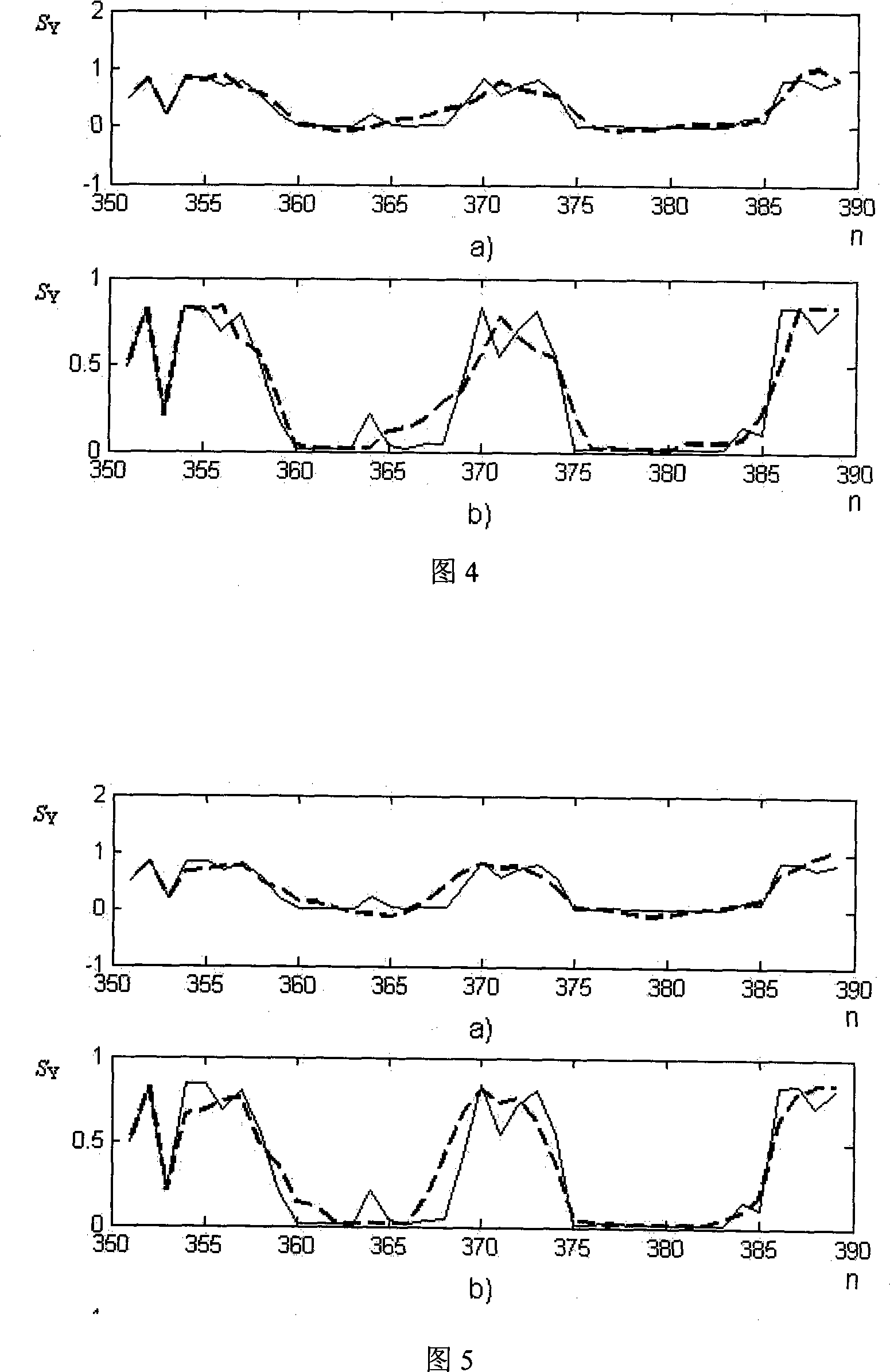

[0051] Embodiment 1 Take the [1 350] points of each IMF component for AR model identification; based on the selected model order, the prediction error power (estimated error power) is minimized, and the smallest possible model order is selected to reduce parameter estimation. The principle of calculation amount calculates the optimal order of each IMF component as 4, 9, 11, 23, 6, and 6 in turn; the Berg recursive algorithm is used to estimate the parameters of the AR model for each IMF component, and based on each IMF component [1 AR model of 350] points; use the AR model established for each IMF component to linearly predict the future [351 389] points, and obtain the predicted value of each IMF component; predict the IMF component according to the completeness of local wave decomposition Sequence reconstruction is used to obtain the discharge state prediction output based on local wave decomposition; and the fit discriminant criterion and discriminant method are used to calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com