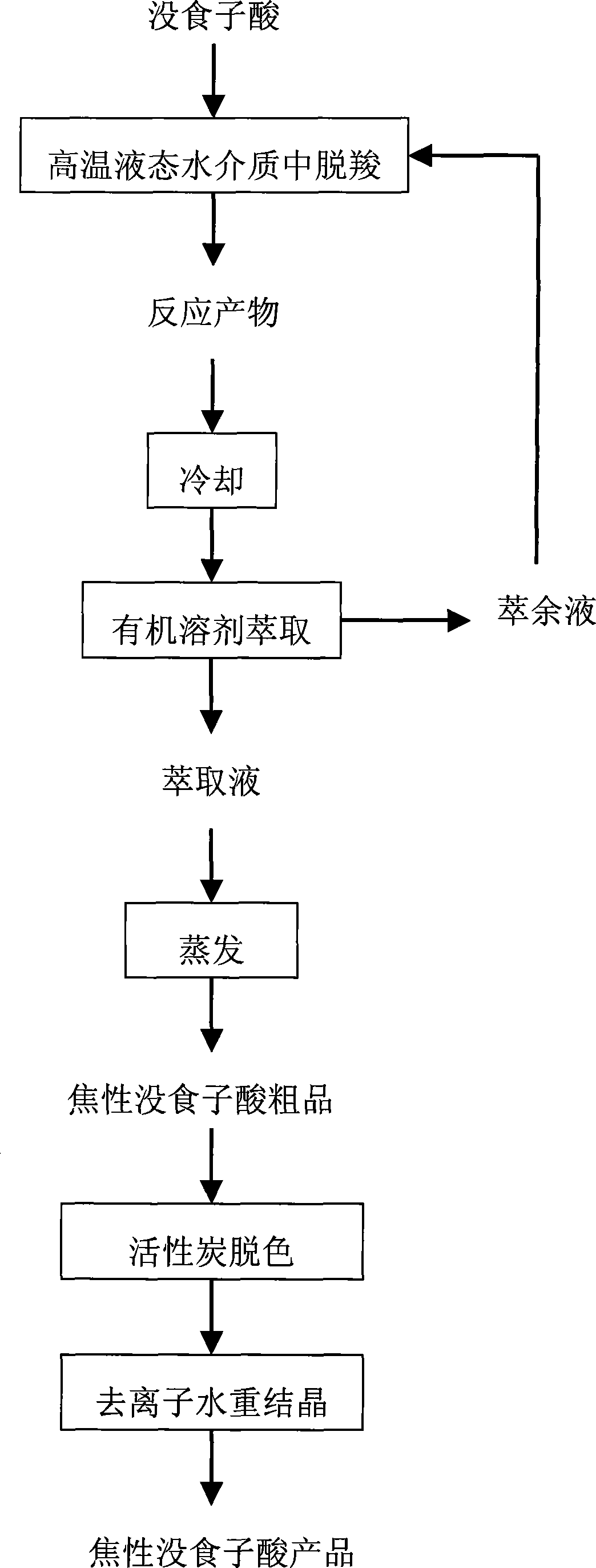

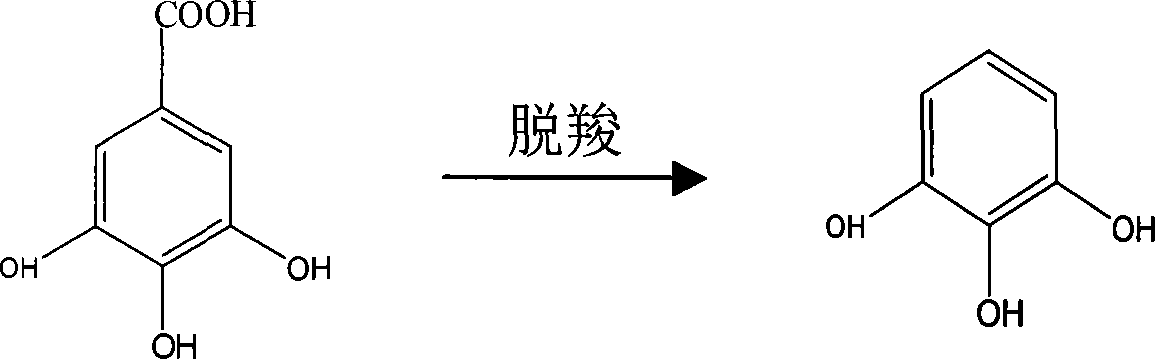

Method for preparing pyrogallic acid from gallic acid in high temperature liquid state water medium by catalyst-free decarboxylating

A technology of pyrogallic acid and high-temperature liquid water, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of shortening the service life of equipment, serious environmental pollution, and low proportion of analytical grade products, and achieves The effect of high raw material utilization rate, simple reaction process and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 267g of deionized water and 133g of gallic acid into a 500mL intermittent high-pressure reactor, the mass ratio of deionized water to gallic acid is 2:1, start stirring, heat up to boiling under normal pressure, open the exhaust valve for 3min, and use steam Exclude the air in the kettle; close the exhaust valve, continue to heat up to 190 ° C for 3.5 hours; the reaction product is cooled to room temperature and extracted with ethyl formate, and the extract is evaporated to remove the organic solvent to obtain the crude product of pyrogallic acid. The crude product is deionized water Dissolved, decolorized by activated carbon, recrystallized, and vacuum dried to obtain 107.4 g of pyrogallic acid product, the product was analyzed by HPLC with a purity of 99.3% (wt%) and a yield of 80.8%.

Embodiment 2

[0028] Add 267g of deionized water and 133g of gallic acid into a 500mL intermittent high-pressure reactor, the mass ratio of deionized water and gallic acid is 2:1, start stirring, heat up to boiling under normal pressure, open the exhaust valve for 4min, and use steam Exclude the air in the kettle; close the exhaust valve, continue to heat up to 210 ° C for 2.5 hours; the reaction product is cooled to room temperature and extracted with ethyl acetate, and the extract is evaporated to remove the organic solvent to obtain the crude product of pyrogallic acid. The crude product is deionized water Dissolved, decolorized with activated carbon, recrystallized, and vacuum dried to obtain 108.8 g of pyrogallic acid product, the product was analyzed by HPLC with a purity of 99.4% (wt%) and a yield of 81.8%.

Embodiment 3

[0030] Add 286g of deionized water and 114g of gallic acid into a 500mL intermittent high-pressure reactor, the mass ratio of deionized water and gallic acid is 2.5:1, start stirring, heat up to boiling under normal pressure, open the exhaust valve for 2min, and use steam Exclude the air in the kettle; close the exhaust valve, continue to heat up to 180 ° C for 4 hours; the reaction product is cooled to room temperature and extracted with methyl acetate, and the extract is evaporated to remove the organic solvent to obtain crude pyrogallic acid, which is dissolved in deionized water , after activated carbon decolorization, recrystallization, and vacuum drying, 99.4g of pyrogallic acid product was obtained, and the product was analyzed by HPLC with a purity of 99.6% (wt%) and a yield of 87.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com