Green extraction method for gelose

An extraction method and green technology, applied in the direction of pharmaceutical formulas, medical preparations containing active ingredients, organic active ingredients, etc., can solve problems affecting the health of workers and polluting the environment, so as to ensure good health, reduce environmental pollution, reduce The effect of alkali reaction concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

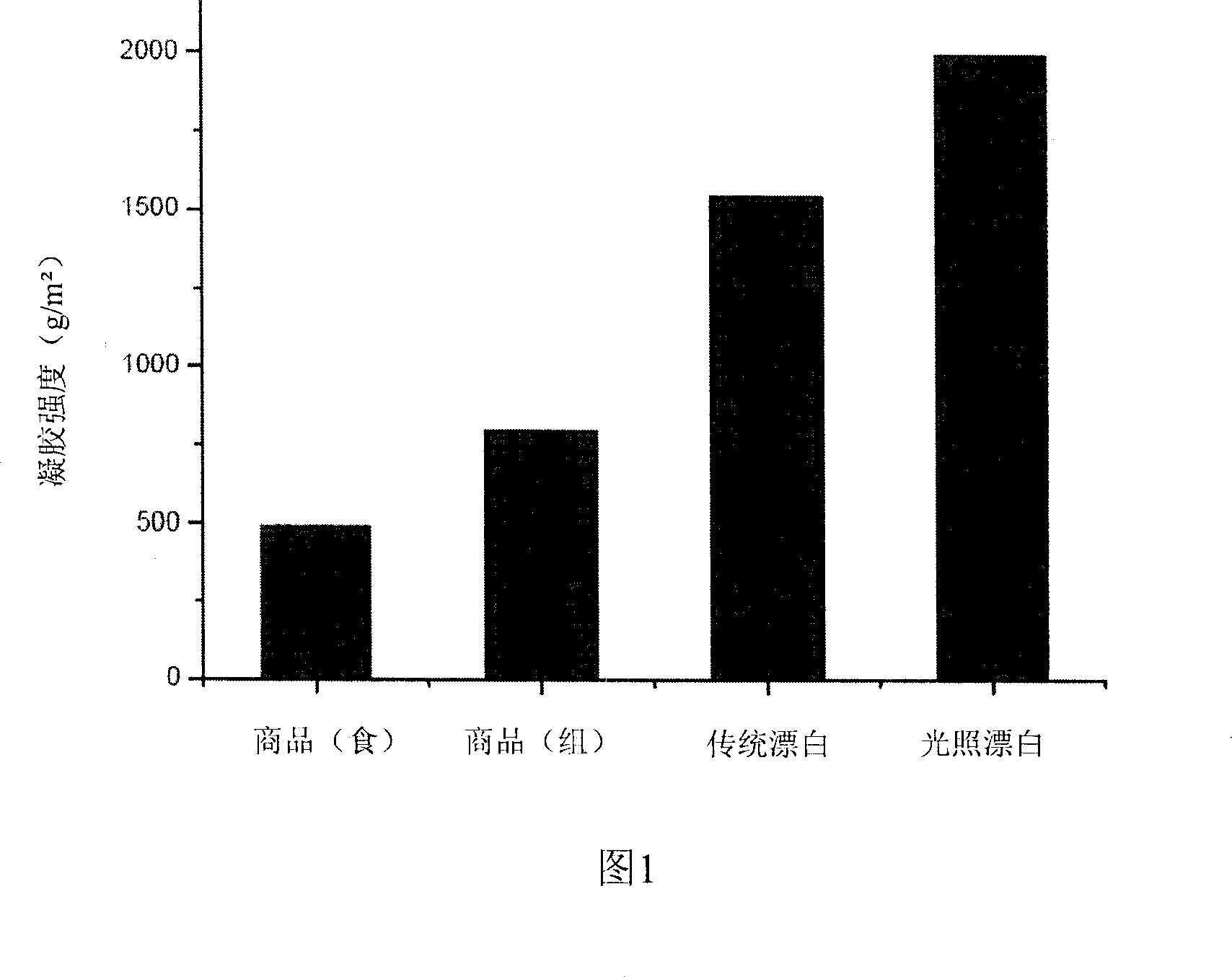

Embodiment 1

[0022] Clean the seaweed, remove sediment and other sundries, control the water, cut into 4 cm lengths; prepare 9% NaOH (mass percentage), the solid-liquid ratio is 1:50, heat to 90 ° C, add algae, and keep the temperature constant React for 1 hour; filter through an 80-mesh sieve, recover the lye, and wash the algae fully with water to approach neutrality; soak in 0.05% oxalic acid for 10 minutes to soften the tissue structure of the algae, and the algae is brownish yellow; soak in fresh water, and the liquid surface is submerged in the algae , loosely distributed, under the condition of light intensity of 120,000 lux, sufficient light for 3 hours, the algae body becomes off-white; water 40 times the weight of the algae is added to the filtered and cleaned algae body, and the gelatin is extracted by boiling under normal pressure for 3 hours , 500-mesh sieve to filter while it is hot; add water to the filter residue for the second gel extraction, the time and water consumption ...

Embodiment 2

[0026] Prepare 3% NaOH and heat to 80°C; add red algae that removes sediment and impurities, the solid-to-liquid ratio is 1:30, and react at a constant temperature for 4 hours; filter through an 80-mesh sieve, recover the lye, and wash the algae to be close to neutral ; Soak in 0.5% oxalic acid for 5 minutes to soften the structure of algae; under the condition of light intensity of 10,000 lux, light for 55 hours, the algae become off-white; water 35 times the weight of algae is added to the algae after filtration and cleaning In the middle, the gel was extracted under 0.07MPa gauge pressure for 1 hour, and filtered while hot with a 200-mesh screen; the filter residue was added with water for the second gel extraction, the time and water consumption were both halved, and the 200-mesh screen was filtered while hot; the filtrate filtered twice Combine, cool and solidify naturally, and cut into thin strips. Freeze the gel strips at -25°C for 28 hours, and the strips are completel...

Embodiment 3

[0029] Clean red algae to remove sediment and impurities; heat to 60°C with 1% NaOH at a solid-liquid ratio of 1:10, add algae, and react at a constant temperature for 6 hours; filter through an 80-mesh sieve, recover the lye, and wash the algae in close proximity to the medium resistance; soak in 0.1% oxalic acid for 8 minutes to soften the structure of the algae; under the condition of light intensity of 50,000 lux and sufficient light for 21 hours, the algae will become off-white; add water 30 times the weight of the algae to the algae, Extract the rubber under 0.06MPa gauge pressure for 4 hours, filter while hot with 80-mesh screen; add water to the filter residue for second gel extraction, the time and water consumption are both halved, and filter while hot with 80-mesh screen; combine the filtrates from the two filtrations, After natural cooling and solidification, cut into thin strips. Pre-cool the gel strips at 5°C for 5 hours; then freeze them at -20°C for 24 hours, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com