Method for controlling double-screw reactor to produce TPU by reaction temperature rising and gel time

A twin-screw reactor and gel time technology, applied in the field of material temperature control, can solve the problems of difficult production of adhesive TPU, slow reaction, flexible production technology, etc., to improve batch-to-batch stability, high production efficiency, The effect of suppressing the occurrence of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] highly reactive system

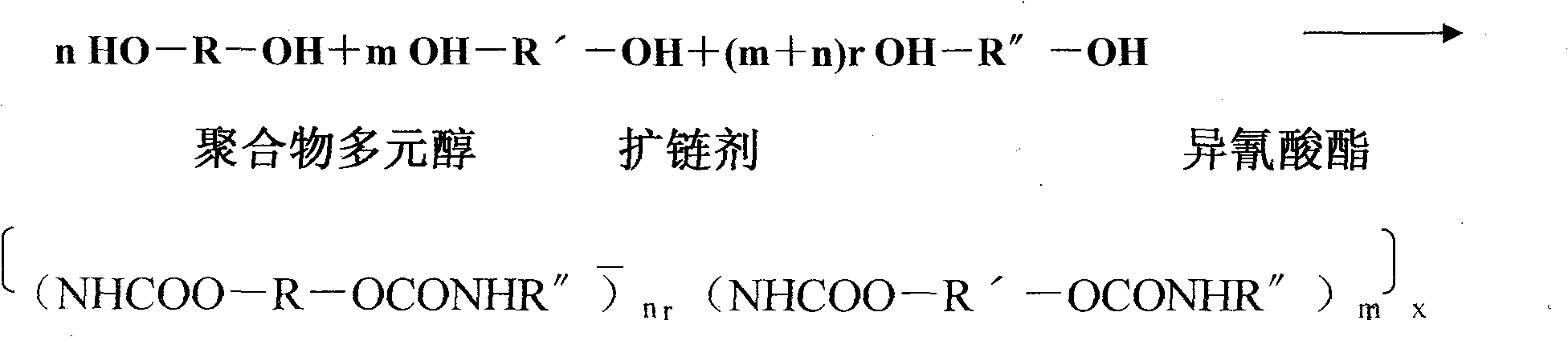

[0020] 1mol of polymer polyol with a molecular weight of 500-1000, 1-10mol of small molecule chain extender, the molar number of isocyanate is the sum of the former two, and the isocyanate index is about 1; the total amount of materials is about 100g; Add the molecular chain extender into the reactor equipped with a stirrer, heat and melt, and dehydrate under reduced pressure for 2 hours at 120°C, return to normal pressure, cool down to 60°C and turn off the heater, add isocyanate, and the temperature rise of the reaction can be measured If it is >50°C / 3 minutes, and the gel time is <90 seconds / 200°C, it can be judged as a high-reactivity system.

[0021] Setting of screw parameters for high reactivity system: material temperature is 60°C-70°C, screw feeding section is set from room temperature to 120°C, reaction section is set at 120-180°C, and output section is set at 180°C; screw speed 20~25HZ; the cutting machine speed is set to fast; the c...

Embodiment 2

[0023] Medium reactive system

[0024] 2000-3000 molecular weight polymer polyol 1mol, small molecule chain extender 0.5-5mol, isocyanate mole number is the sum of the former two, isocyanate index is about 1; the total amount of materials is about 100g; polymer polyol, small Molecular chain extender is added to the reactor equipped with a stirrer, heated and melted, and dehydrated under reduced pressure for 2 hours at 120°C, then returned to normal pressure, cooled to 80°C and turned off the heater, and the reaction temperature can be measured by adding isocyanate 20-50°C / 10 minutes, gel time 90-300 seconds / 200°C, it can be judged as a medium reactive system.

[0025] Setting of medium reactive screw parameters: material temperature is 70°C-80°C, screw feed section is set from 120-140°C, reaction section is set at 160-200°C, discharge section is set at 190°C; screw speed 16 ~20HZ; the cutting machine speed is set to medium; the cooling water temperature is set to 15 ~ 25 ℃. ...

Embodiment 3

[0027] low reactivity system

[0028] 1 mol of polymer polyol with a molecular weight above 3000, 0.5-5 mol of small molecule chain extender, the molar number of isocyanate is the sum of the former two, and the isocyanate index is about 1; the total amount of materials is about 100g; Add the chain extender into the reactor equipped with a stirrer, heat and melt, and dehydrate under reduced pressure for 2 hours at 120°C, return to normal pressure, cool down to 80°C and turn off the heater, add isocyanate, the reaction temperature can be measured as 300 seconds / 200°C, it can be judged as a low reactivity system.

[0029] Setting of screw parameters with low reactivity: material temperature is 80°C-100°C, screw feeding section is set from 120-160°C, reaction section is set at 160-210°C, discharge section is set at 200°C; screw speed 12 ~16HZ; the cutting machine speed is set to low speed; the cooling water temperature is set to 10 ~ 15 ℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com