Volume type assembled multifunctional heat exchanger

A heat exchanger and assembly type technology is applied in the fields of showers, volumetric assembled wall-mounted gas heating, heat exchangers, and antifreeze multifunctional heat exchangers. High technical requirements, to achieve the effect of high labor intensity of workers, improved labor productivity, and clean and hygienic working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

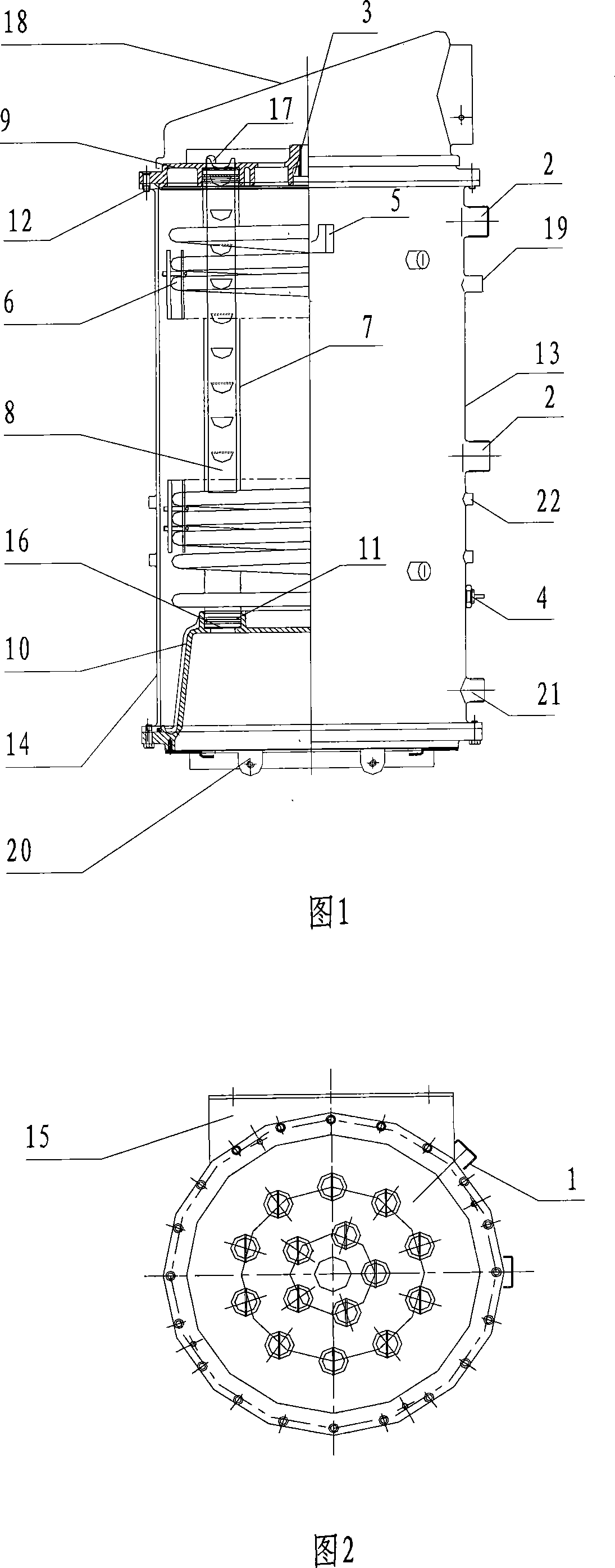

[0021] As shown in Figures 1 and 2, the present invention consists of a housing 13, an electric heater 4, a coil 6, inner and outer finned tubes 7, a spoiler 8, an upper tube plate 9, a combustion chamber 10, a fastening bracket 15, a condensation The water absorber 16, the burner fixing part 20, the emptying / replenishing water port 21, and the temperature limiter of the heating belt are composed of 22. All parts are socket-type, connected by tongue and groove, and fixed and positioned by multiple screws. The pipe fittings connected to the heater are connected to the heat exchanger through seals, and external interfaces are provided on the shell: domestic hot water thread head 1, heating thread head 2 and overflow thread head 3, and coil pipes 6 and The inner and outer ribbed tubes 7 are provided with spoilers 8; the inside and outside of the housing are provided with electric heaters 4, the lower part of the housing is provided with a combustion chamber 10, and the upper part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com