Surface array semiconductor laser light beam shaping device

A beam shaping and semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of poor beam quality, difficulty in obtaining high-brightness small spots, etc., and achieve the effect of simple structure, convenient adjustment, and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

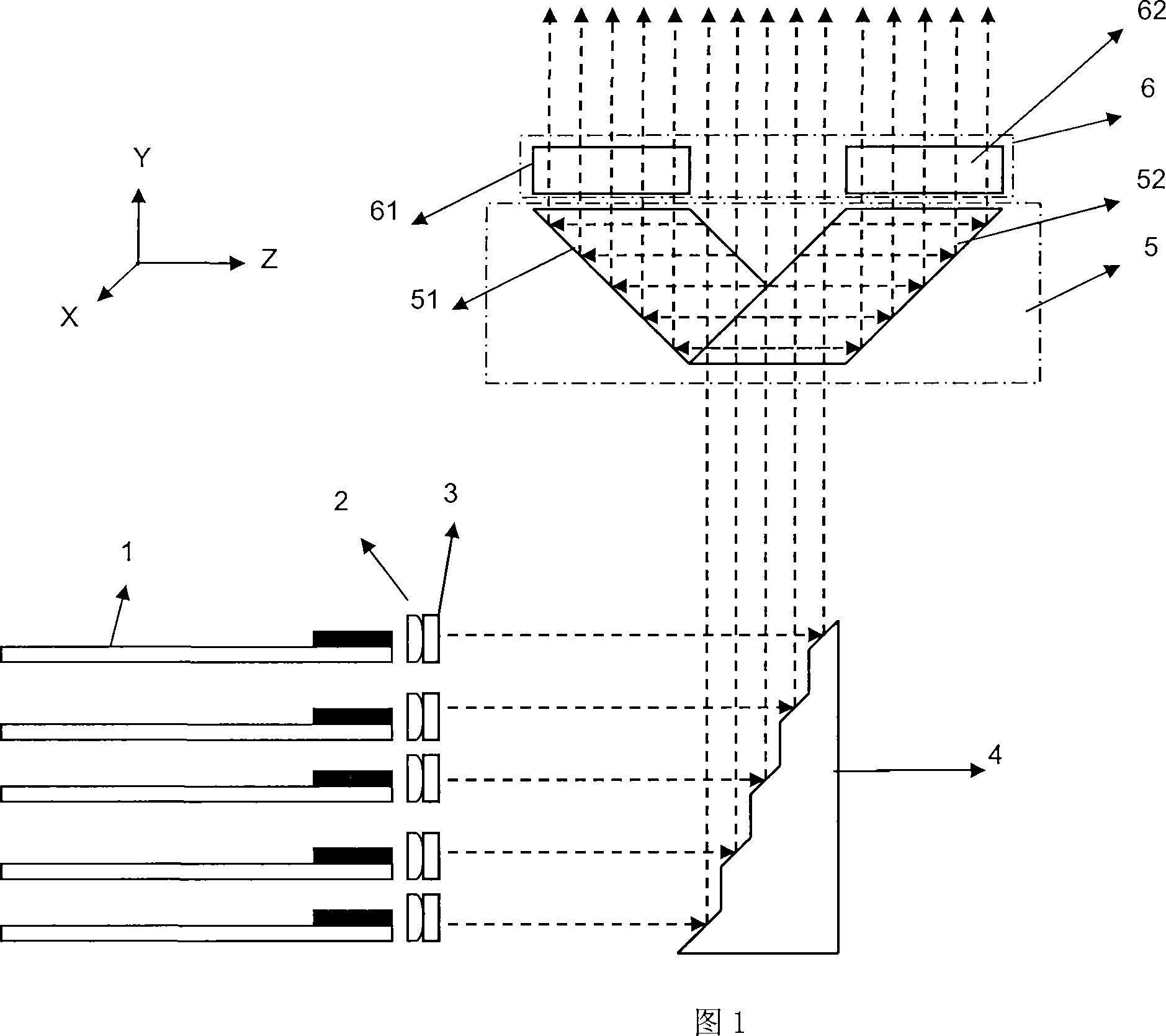

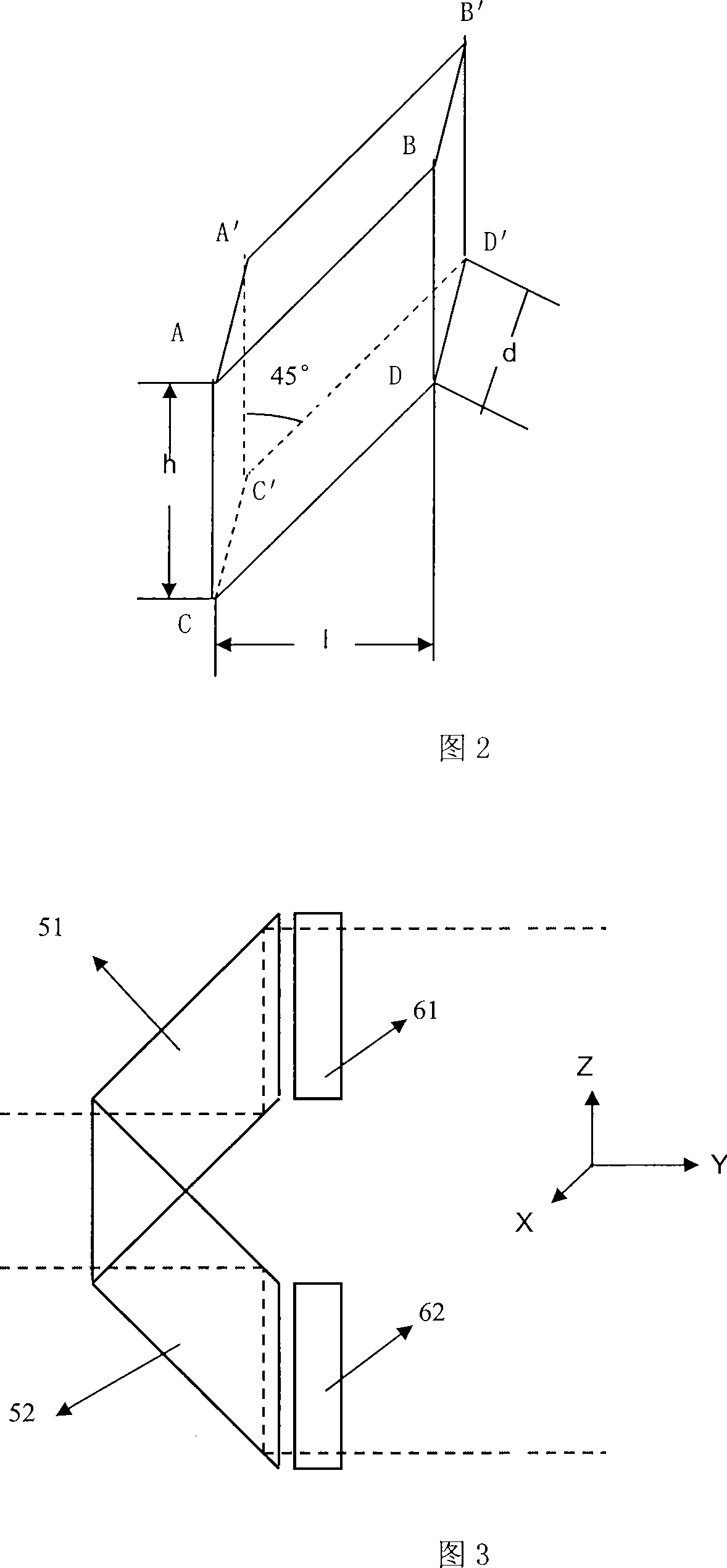

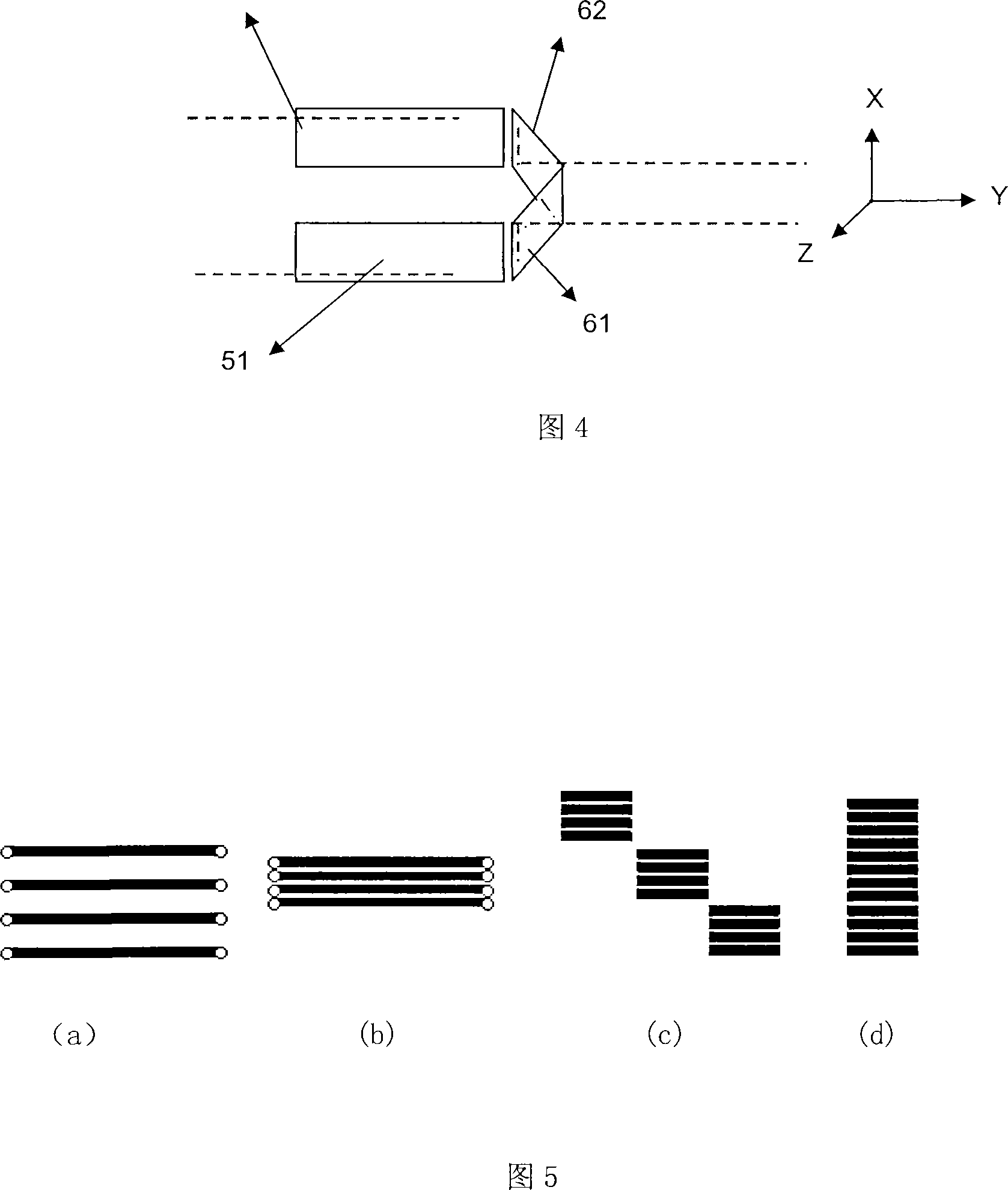

[0019] As shown in Figure 1, the beam shaping device of the area array semiconductor laser of the present invention comprises fast axis collimator mirror 2, slow axis collimator mirror 3, stepped mirror 4, the first parallelepiped prism group 5, the second parallelepiped prism group 6.

[0020] The light beam emitted by the area array semiconductor laser propagates along the Z-axis direction; before the light beam changes direction without step mirror 4, the fast axis direction is the Y-axis direction shown in Figure 1, and the slow axis direction is the X-axis direction shown in Figure 1 After the light beam is changed in direction by the stepped mirror 4, the fast axis direction is the Z-axis direction shown in Figure 1, and the slow axis direction is the X-axis direction shown in Figure 1.

[0021] The fast-axis collimator 2 adopts a cylindrical lens, a semi-cylindrical lens or a graded-index lens; the slow-axis collimator 3 adopts a microcylindrical lens array. The fast-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com