Apparatuses and methods for manipulating droplets on a printed circuit board

A printed circuit board, printed circuit technology, applied in chemical instruments and methods, biochemical equipment and methods, microelectronics and microstructure devices, etc., can solve problems such as low resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

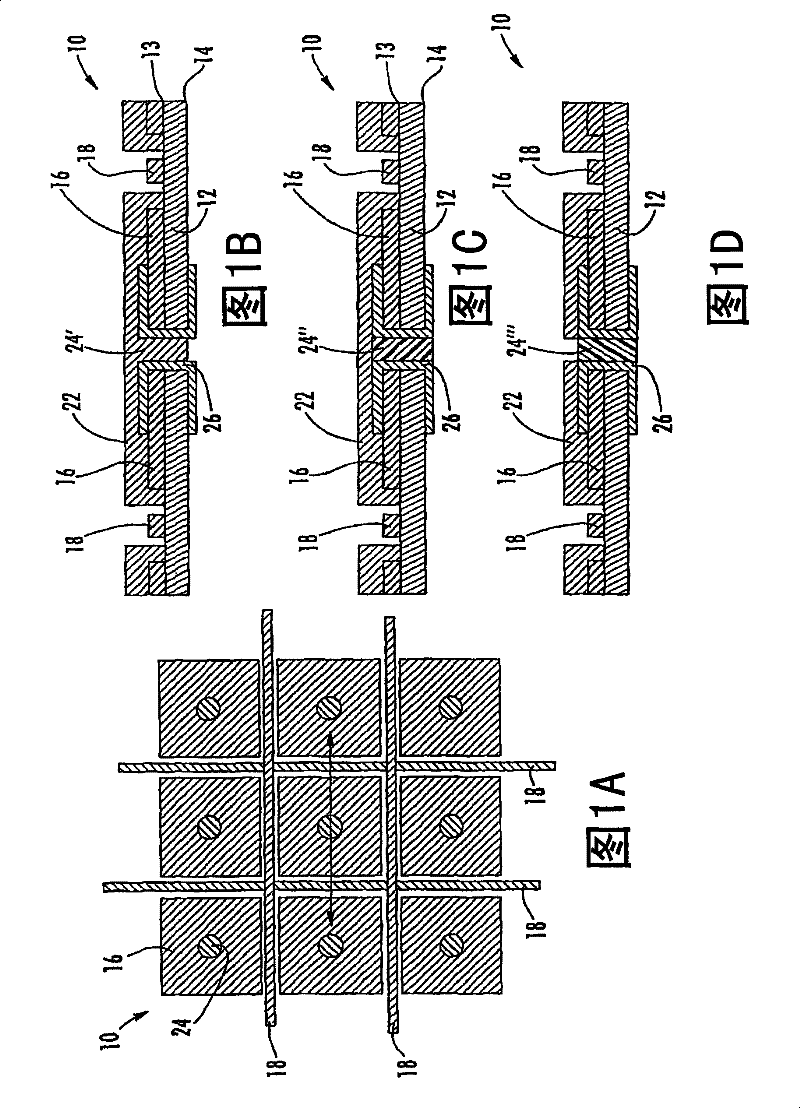

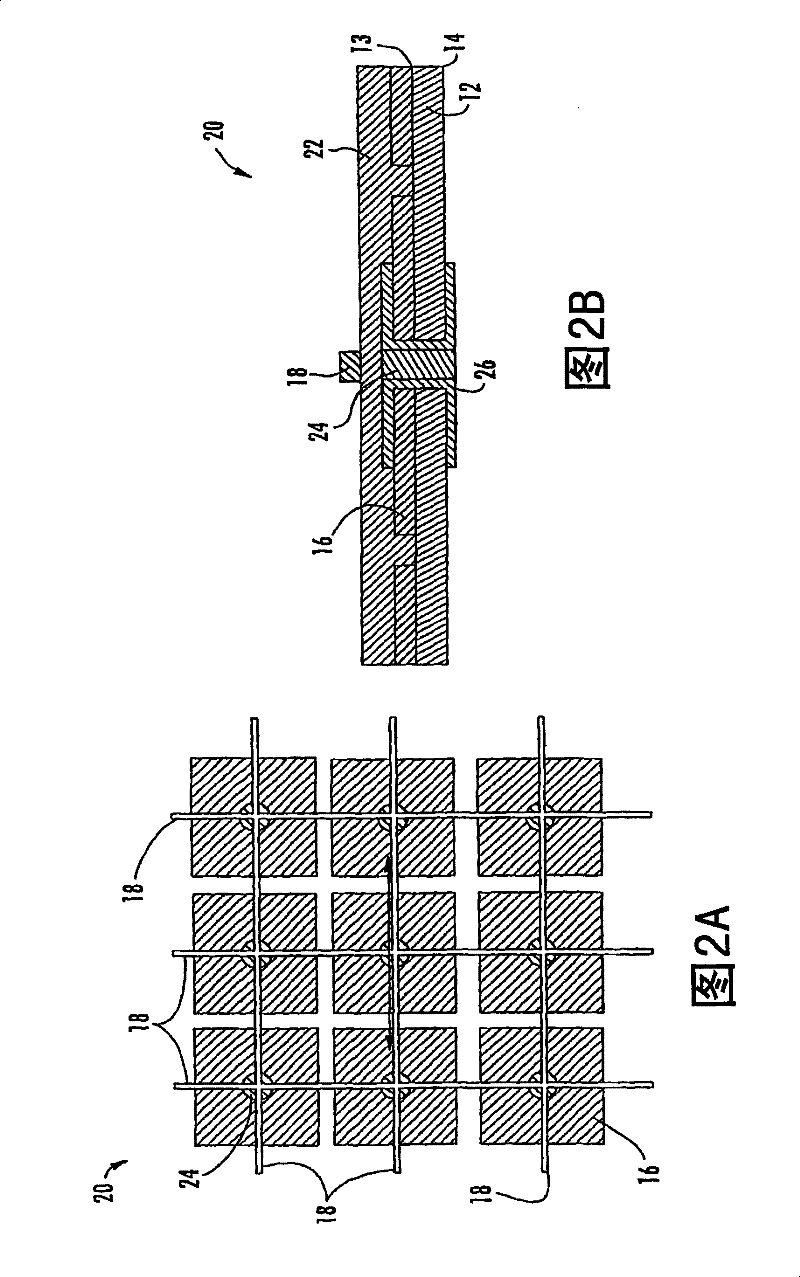

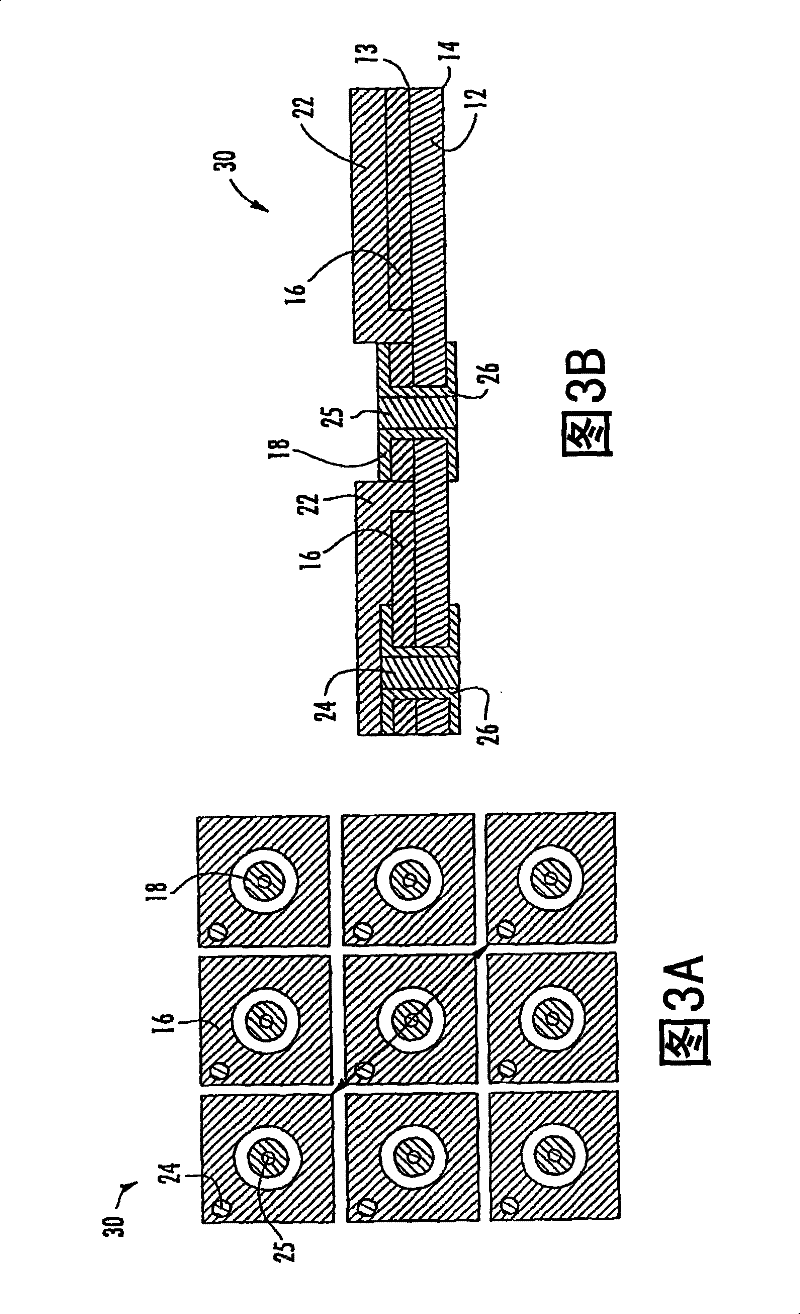

[0104] Having discussed above general embodiments and processes of the present invention, a more specific embodiment of the manufacture of a device for manipulating microvolume liquid samples, wherein the device comprises a printed circuit board substrate, will now be discussed.

[0105] In a preferred embodiment, a 1 / 4 Oz (~9 μm) clad copper. Drill 8mil vias through the substrate. These vias are then plated with copper and filled with solder mask or epoxy. Preferably, the vias are button-plated to a thickness of about 5 μm, with specific vias plated, while the rest of the plate is covered by a mask. Mechanically level the button, then fill the vias with solder mask or non-conductive epoxy. After the vias are processed, a flash plating step is performed to a thickness of less than 5 μm. In cases where unfilled vias are desired, another drilling step can be performed to obtain unfilled holes and, if necessary, electroplating. Temporarily, the designed electrode pattern ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com