Polarizable electrode, capacitor using same, and method for manufacturing polarizable electrode

A polarized electrode and conductive agent technology, applied in the field of capacitors, can solve the problem of large surface area of activated carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

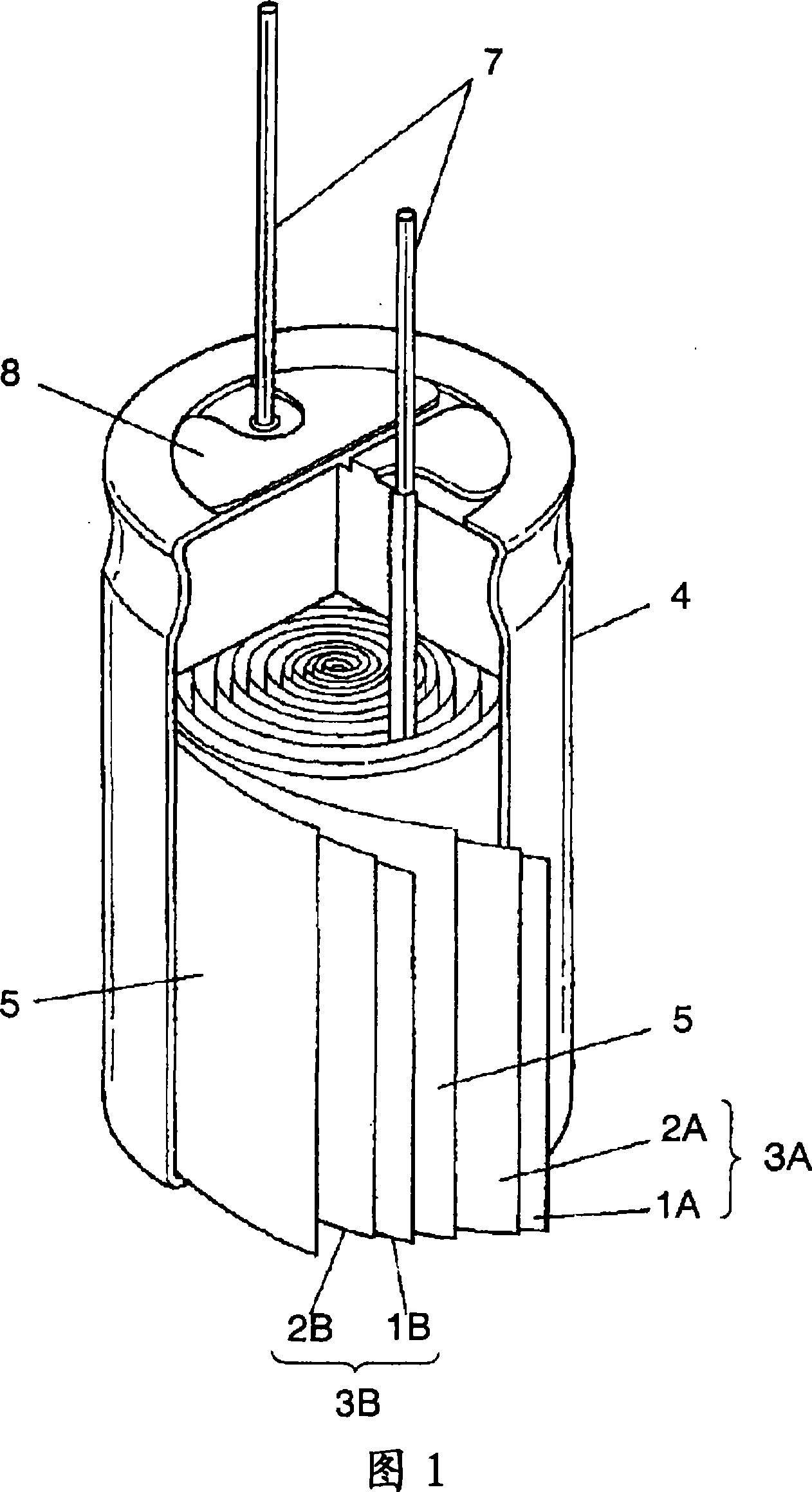

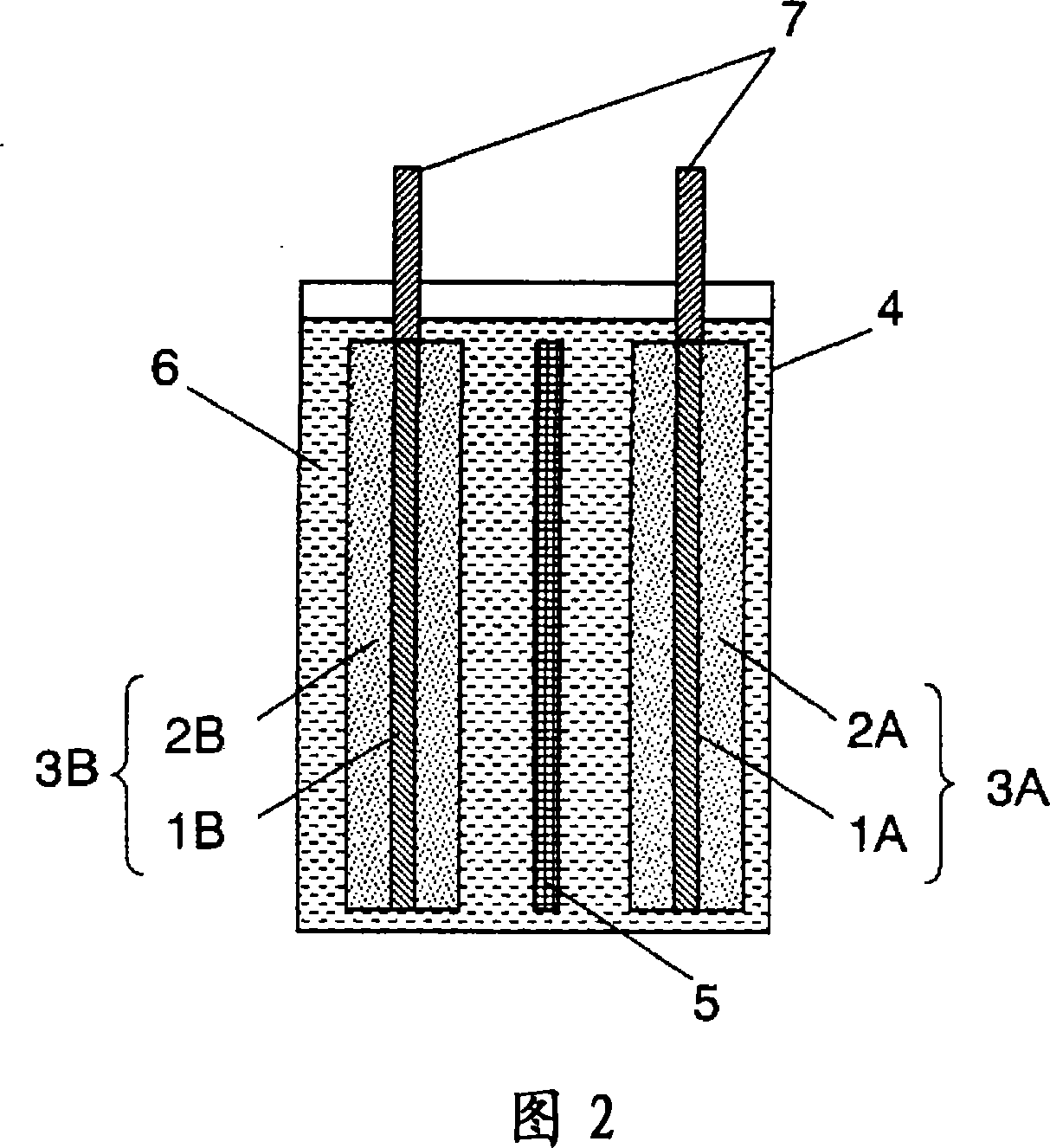

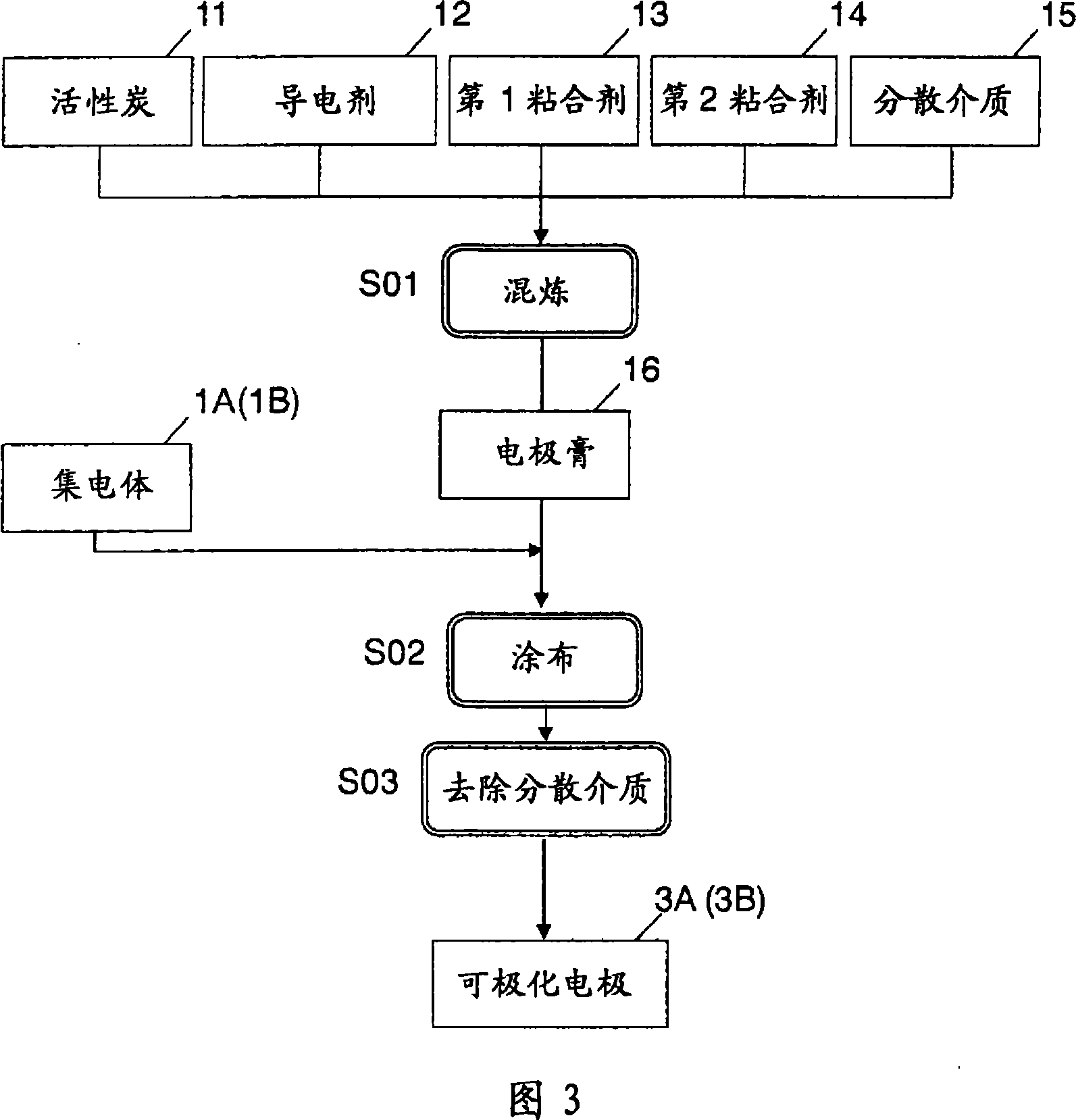

[0036] FIG. 1 is a partially cutaway perspective view of a capacitor according to an embodiment of the present invention, and FIG. 2 is a conceptual configuration diagram of the capacitor. Fig. 3 is a diagram showing a method of fabricating a polarizable electrode. This capacitor has: first and second polarizable electrodes (hereinafter referred to as electrodes) 3A, 3B; a diaphragm 5 interposed between the electrodes 3A, 3B; Electrolyte 6 inside 4.

[0037] Lead wires 7 are connected to the electrodes 3A and 3B, respectively. Electrolytic solution 6 is filled between electrodes 3A, 3B and separator 5 . Electrodes 3A, 3B are wound through separator 5 . The sealing material 8 seals the opening of the case 4 . Through holes are provided in the sealing material 8 so that the lead wires 7 are exposed to the outside. The casing 4 is made of aluminum, for example.

[0038] The electrode 3A has a first current collector (hereinafter referred to as a current collector) 1A and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com