High-pressure pulse electric sterilization process device for liquid food

A high-voltage pulsed electric field and liquid food technology, which is applied in food science and other fields, can solve the problems of high technical difficulty, unreasonable structure of the sterilization chamber, and high cost of the sterilization device, and achieve the effect of simple circuit structure, obvious sterilization rate, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

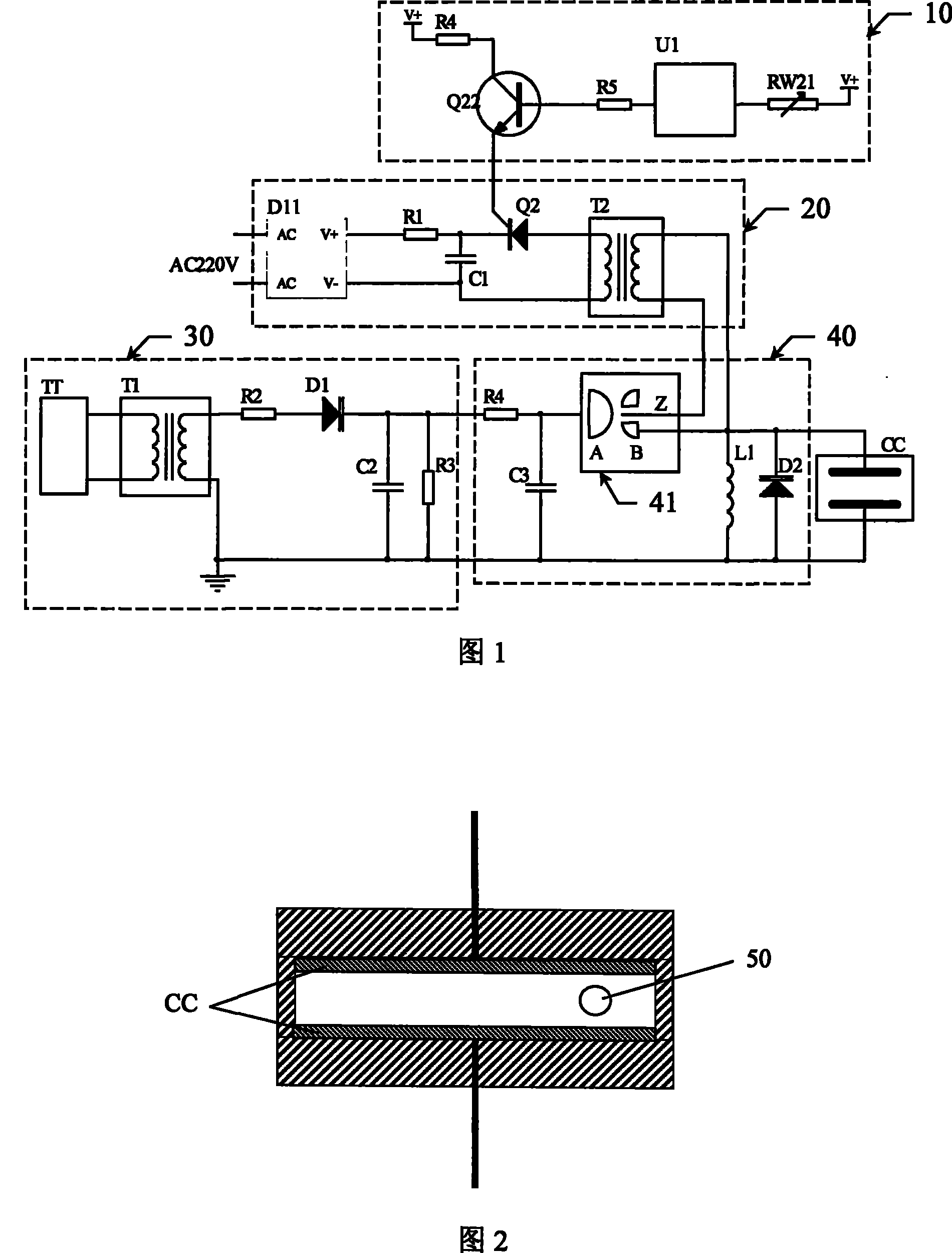

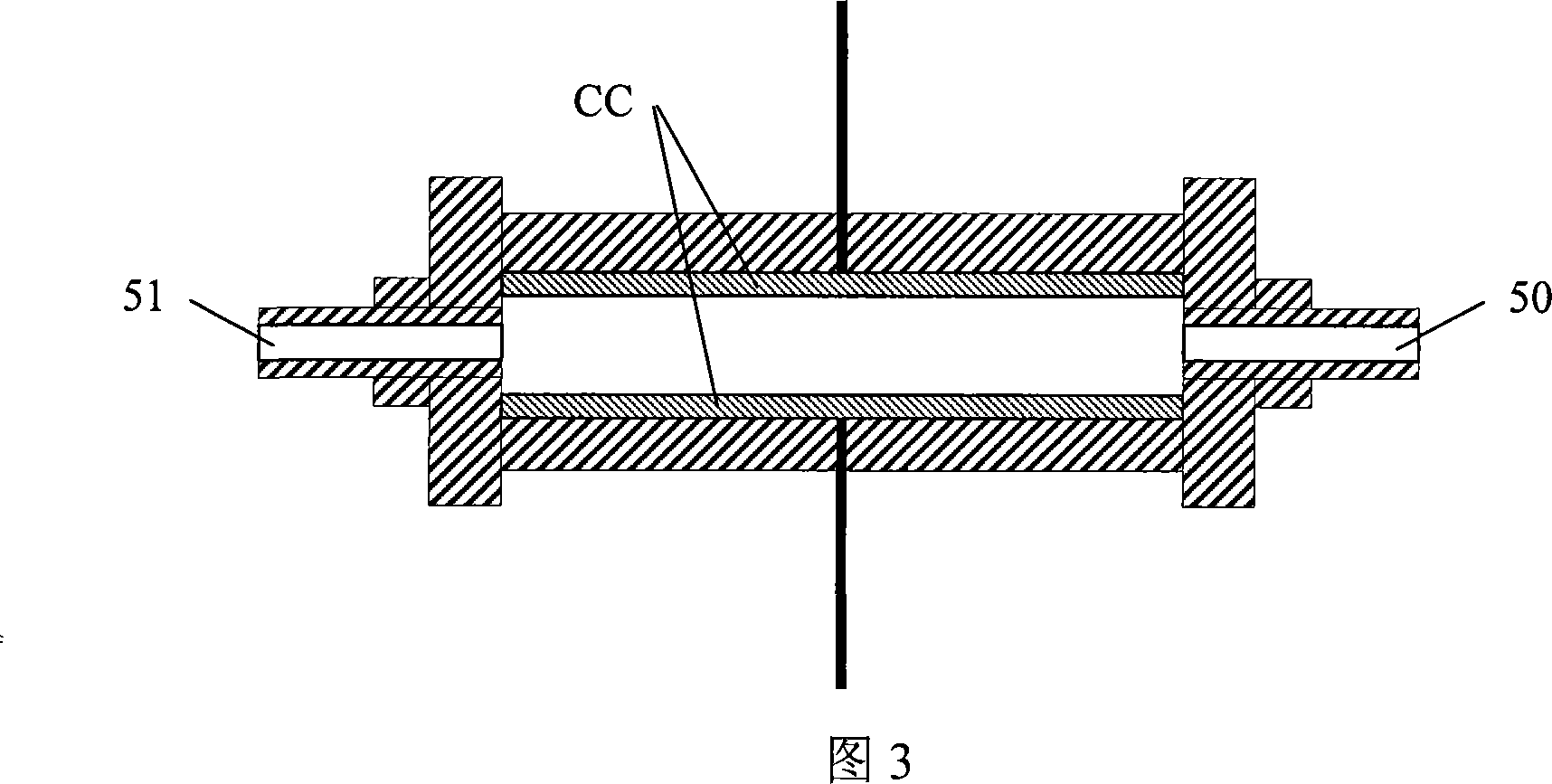

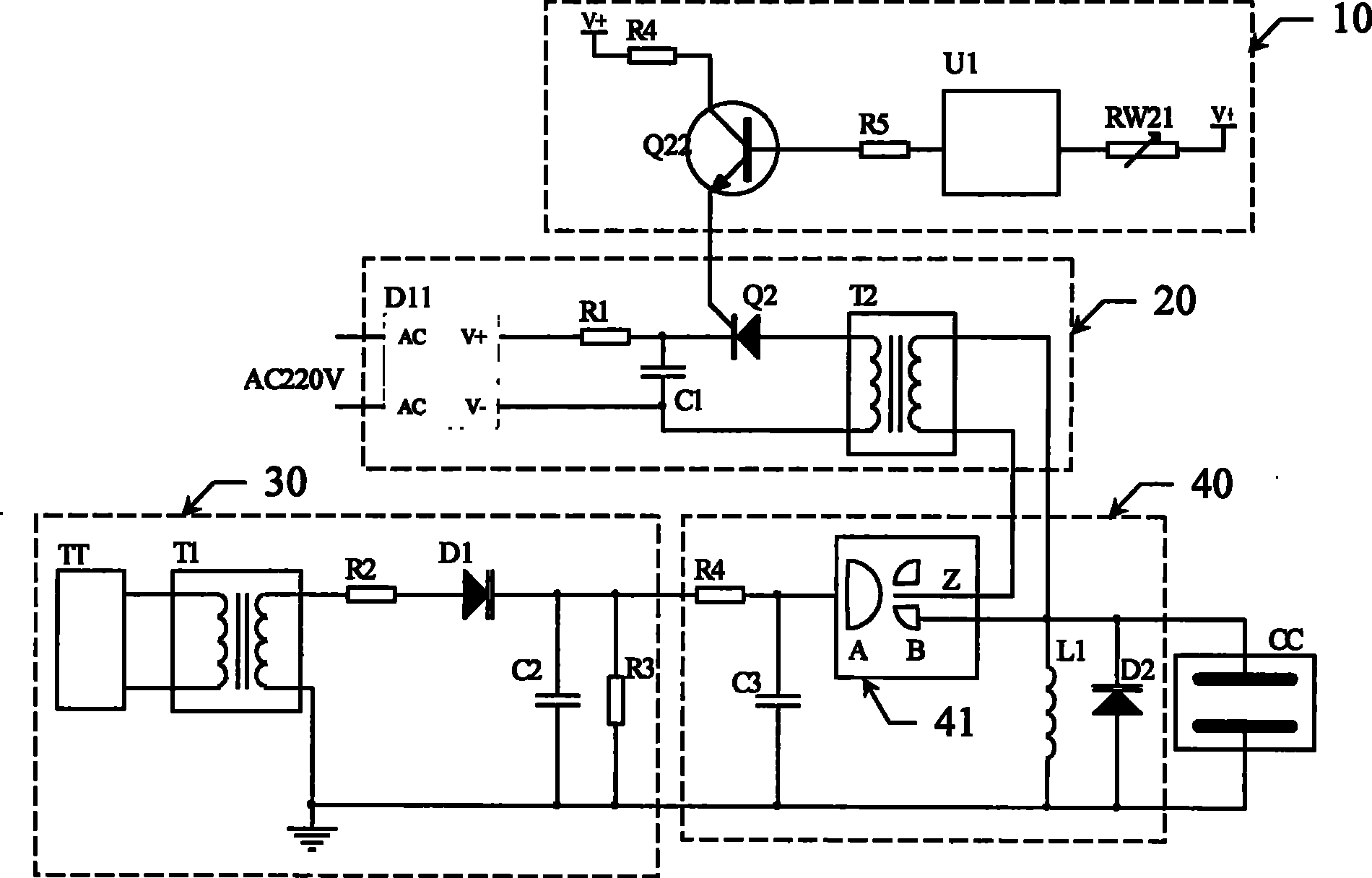

[0008] Embodiment 1: The high-voltage pulse electric field sterilization treatment device for liquid food is composed of a pulse trigger generating circuit, a sterilization capacitor CC and a processing chamber. The pulse trigger generating circuit is composed of a pulse signal generating circuit 10, a pulse trigger circuit 20, and a booster circuit. 30. The discharge circuit 40 is composed of a pulse signal generating circuit 10 generating a pulse signal with a frequency of 0.5Hz to 50Hz. The pulse signal output terminal of the pulse signal generating circuit 10 is connected to the control signal input terminal of the pulse trigger circuit 20. The pulse signal The two pulse signal output terminals of the trigger circuit 20 are connected with the two pulse control signal input terminals of the discharge circuit 40, the voltage signal input terminals of the discharge circuit 40 are connected with the voltage signal output terminals of the booster circuit 30, and the discharge cir...

specific Embodiment approach 2

[0011] Embodiment 2: The difference between this embodiment and the high-voltage pulse electric field sterilization treatment device for liquid food described in Embodiment 1 is that the pulse trigger circuit 20 is composed of a rectifier bridge D11, a first resistor R1, a first capacitor C1, SCR Q2 and pulse transformer T2 are composed, the two AC input ends of the rectifier bridge D11 are respectively connected to the two power output ends of the external AC 220V power supply, and one end of the first resistor R1 is connected to the positive output end of the rectifier bridge D11 The other end of the first resistor R1 is respectively connected to one end of the first capacitor C1 and the cathode of the thyristor Q2, and the other end of the first capacitor C1 is connected to the negative output end of the rectifier bridge D11. The anode of the silicon controlled silicon Q2 is connected to the negative output terminal of the rectifier bridge D11 through the primary coil of the...

specific Embodiment approach 3

[0013] Specific embodiment three: The difference between this embodiment and the liquid food high-voltage pulse electric field sterilization treatment device described in specific embodiment one or two is that the boost circuit 30 is composed of a voltage regulator TT, a step-up transformer T1, a second The resistor R2, the first silicon stack D1, the charging capacitor C2 and the third resistor R3 are composed. The two signal output ends of the voltage regulator TT are respectively connected to the two ends of the primary coil of the step-up transformer T1. The step-up transformer One end of the secondary coil of T1 is connected to one end of the second resistor R2, the other end of the secondary coil of the step-up transformer T1 is connected to the power ground, the other end of the second resistor R2 is connected to the first silicon stack D1 The anode is connected, the cathode of the first silicon stack D1 is connected to the voltage signal input end of the discharge circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com