Method for preparing high purity oxygen by double-tower low temperature rectification

A low-temperature rectification and high-purity oxygen technology, which is applied in oxygen preparation, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of small production scale and high price of adsorption materials, and achieve low cooling loss and heat exchange effect Good, guaranteed removal of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

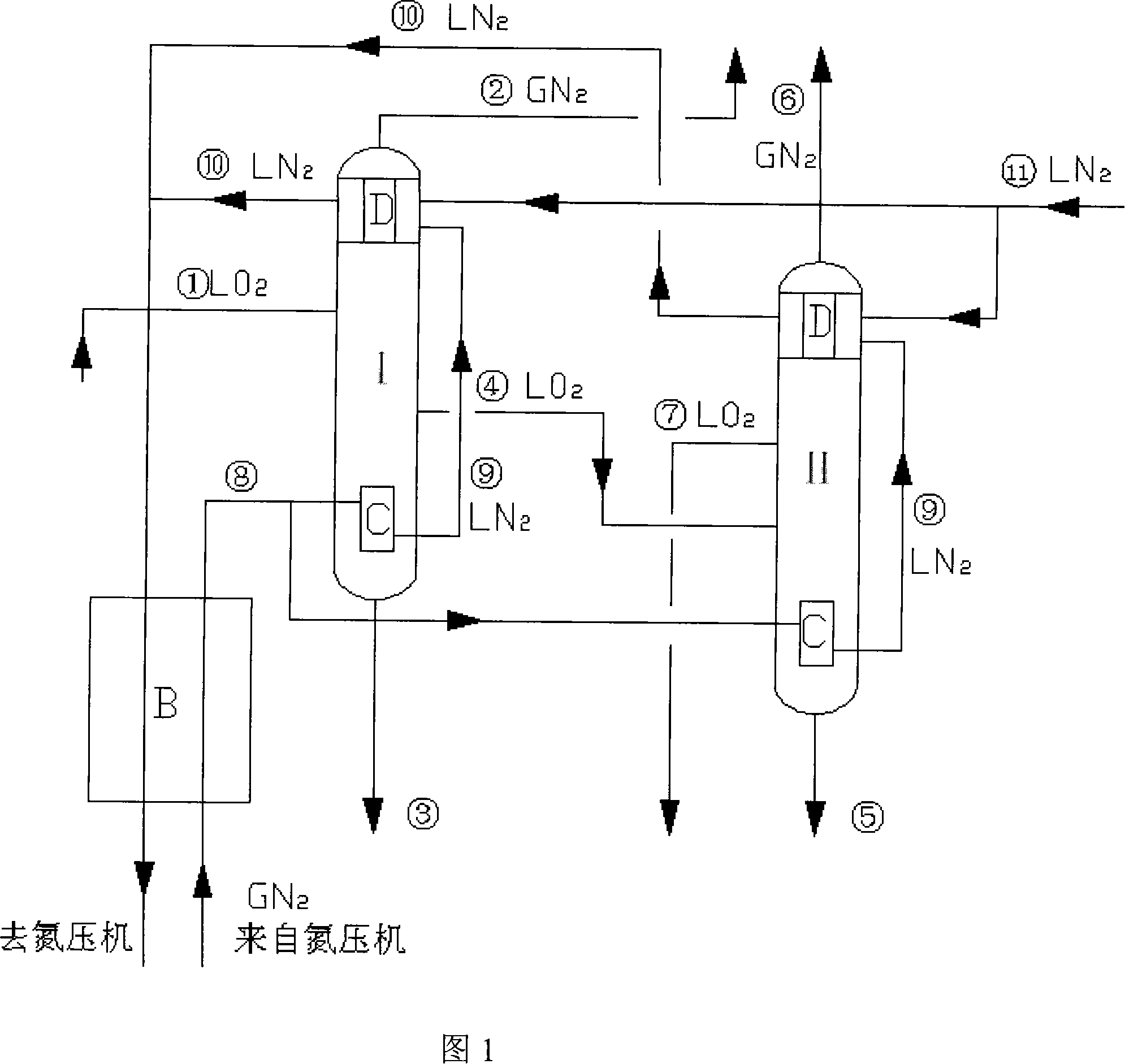

[0026] The present invention will be discussed in more detail below with reference to the accompanying drawings of examples. Now see Figure 1,

[0027] The method for preparing high purity oxygen by double-tower cryogenic rectification includes:

[0028] a. Two structured packing rectification towers with condenser D at the top and evaporator C at the bottom, I rectification tower and II rectification tower, each rectification tower is divided into three rectification sections, the upper, middle and lower sections. A main heat exchanger B is provided outside the distillation tower;

[0029] b. The raw material of industrial liquid oxygen 1 with a pressure of 0.2MPa and a temperature of 95K is directly introduced into the middle section of the I rectification tower, and through low-temperature rectification in the tower, the resulting pressure is 0.13MPa, the temperature is about 93K, and the components containing 7.5% argon Gas 2 is discharged from the top of the tower, resulting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com