Method for controlling transfer single-wall carbon nanotube array structure

A single-walled carbon nanotube, array structure technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of inability to maintain the original structure and low success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

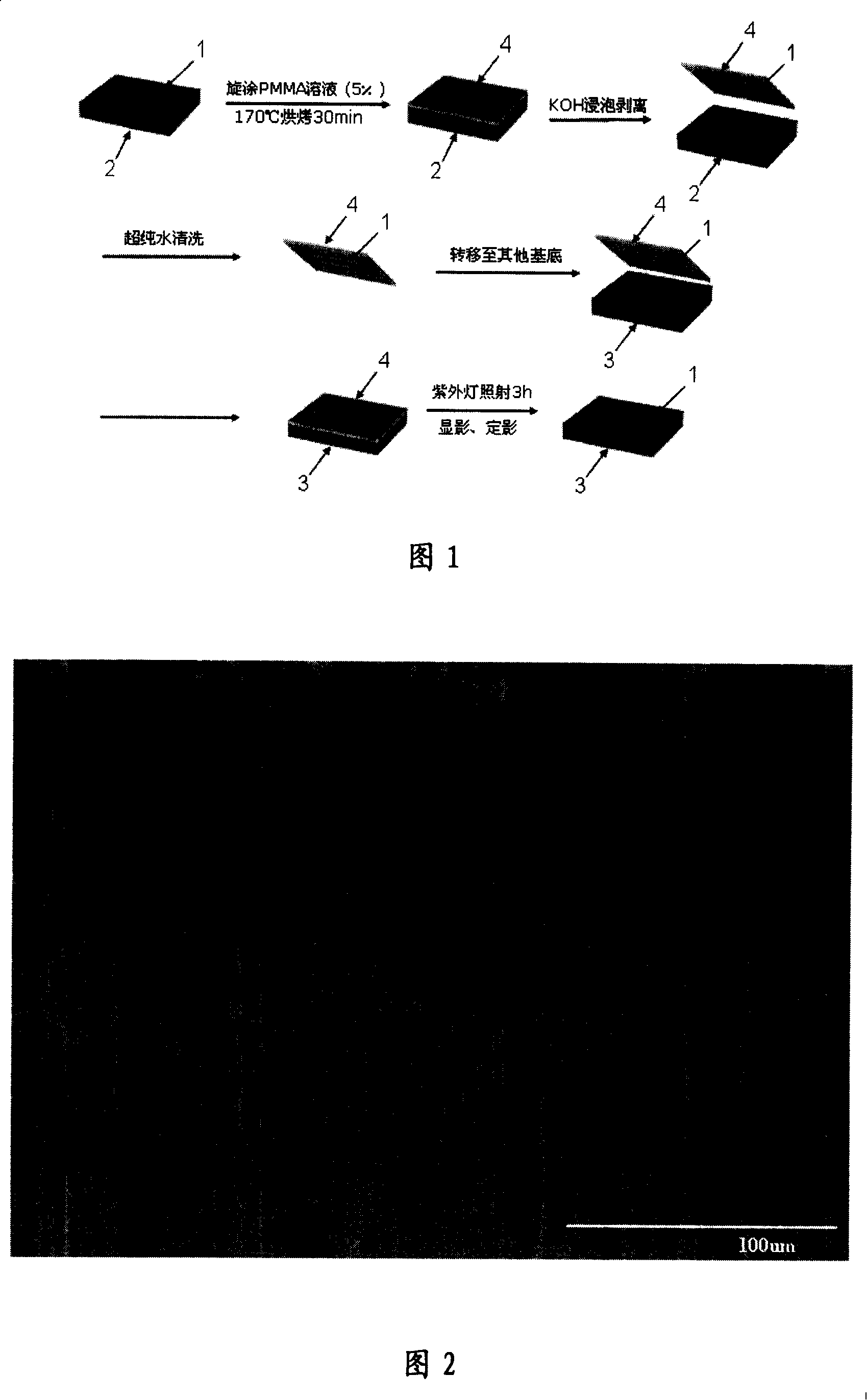

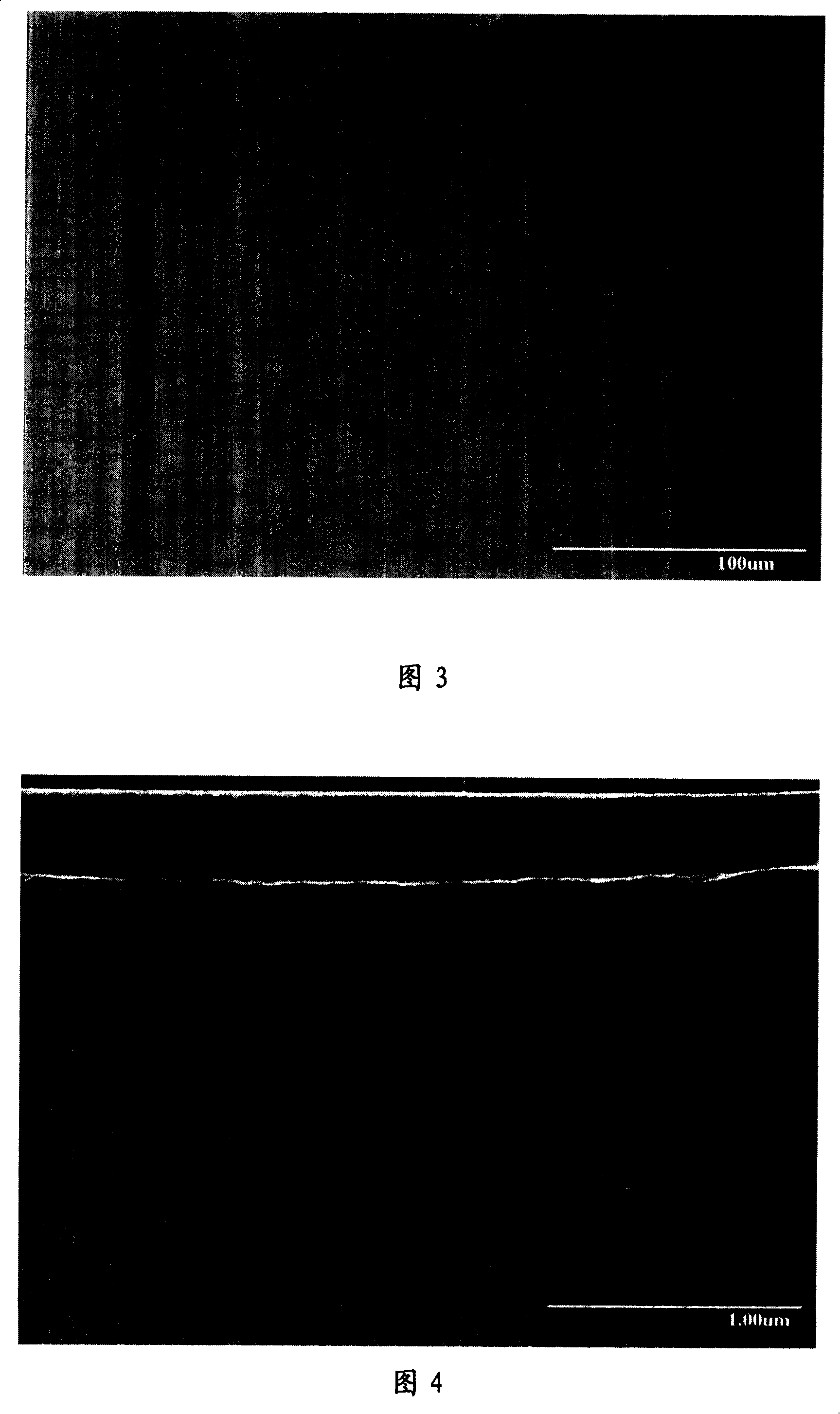

[0026] (1) Using chemical vapor deposition (CVD) on SiO 2 On the surface of the / Si substrate, an array structure of ultra-long parallel single-walled carbon nanotubes with gas flow orientation is grown, as shown in Figure 2;

[0027] (2) the anisole solution of one deck PMMA is spin-coated on its surface, and in 110 ℃ of baking 45 minutes, remove solvent, form PMMA film;

[0028] (3) The SiO covered with PMMA film 2 / Si substrate placed in 1mol·L -1 Heating in the sodium hydroxide solution makes it slightly boil until the PMMA film is separated from the surface and floats;

[0029] (4) Wash the PMMA film with ultrapure water and stick it on another SiO 2 / On the surface of the Si substrate, dry it with high-purity nitrogen and bake it at 110°C for 45 minutes;

[0030] (5) The second piece of SiO with PMMA film on the surface 2 / Si substrate placed under ultraviolet light for 3 hours, and then developed, the PMMA film was removed during the fixing process, and the SiO 2...

Embodiment 2

[0032] (1) Using chemical vapor deposition (CVD) to grow airflow-oriented ultra-long parallel single-walled carbon nanotube array structures on the surface of Si substrates;

[0033] (2) the anisole solution of one deck PMMA is spin-coated on its surface, and in 130 ℃ of baking 40 minutes, remove solvent, form PMMA film;

[0034] (3) Place the Si substrate covered with PMMA film in 2mol L -1 Heating in the sodium hydroxide solution makes it slightly boil until the PMMA film is separated from the surface and floats;

[0035] (4) Wash the PMMA film with ultrapure water, and stick it on the SiO with Pt electrode structure 2 / Si substrate, blow dry with high-purity nitrogen, and bake at 130°C for 40 minutes;

[0036] (5) SiO with a Pt electrode structure with a PMMA film on the surface 2 / Si substrate placed under ultraviolet light for 3 hours, and then developed, the PMMA film was removed during the fixing process, and the ultra-long parallel single-walled carbon nanotube arra...

Embodiment 3

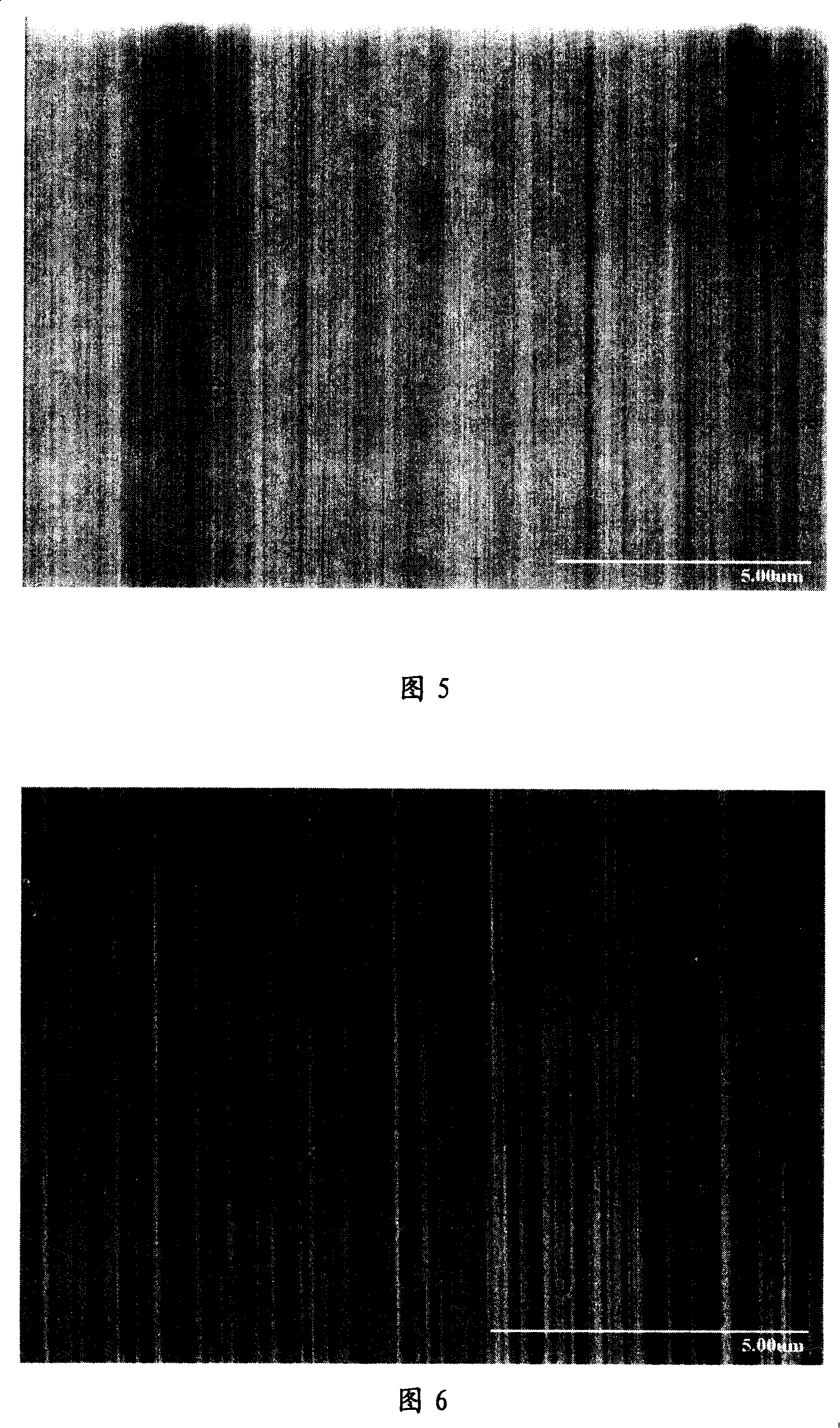

[0038] (1) using chemical vapor deposition (CVD) to grow a single-walled carbon nanotube array structure with a crystal plane orientation on the a crystal plane of the Sapphire substrate, as shown in Figure 5;

[0039] (2) Spin-coat an anisole solution of one deck PMMA on its surface, and bake at 170 DEG C for 30 minutes to remove the solvent to form a PMMA film;

[0040] (3) Place the Sapphire substrate coated with PMMA film in 4mol L -1 Heating in the potassium hydroxide solution makes it slightly boil until the PMMA film is separated from the surface and floats;

[0041] (4) Wash the PMMA film with ultrapure water and stick it on SiO 2 / Si substrate, blow dry with high-purity nitrogen, and bake at 170°C for 30 minutes;

[0042] (5) SiO with PMMA film on the surface 2 / Si substrate placed under ultraviolet light for 3 hours, and then developed, the PMMA film was removed during the fixing process, and the parallel single-walled carbon nanotube array structure grown on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com