Sludge aerobic composting reactor

An aerobic composting and reactor technology, which is applied in the fields of sewage/sludge fertilizer, application, organic fertilizer, etc., can solve the problems of loss of nutrients, secondary environmental pollution, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

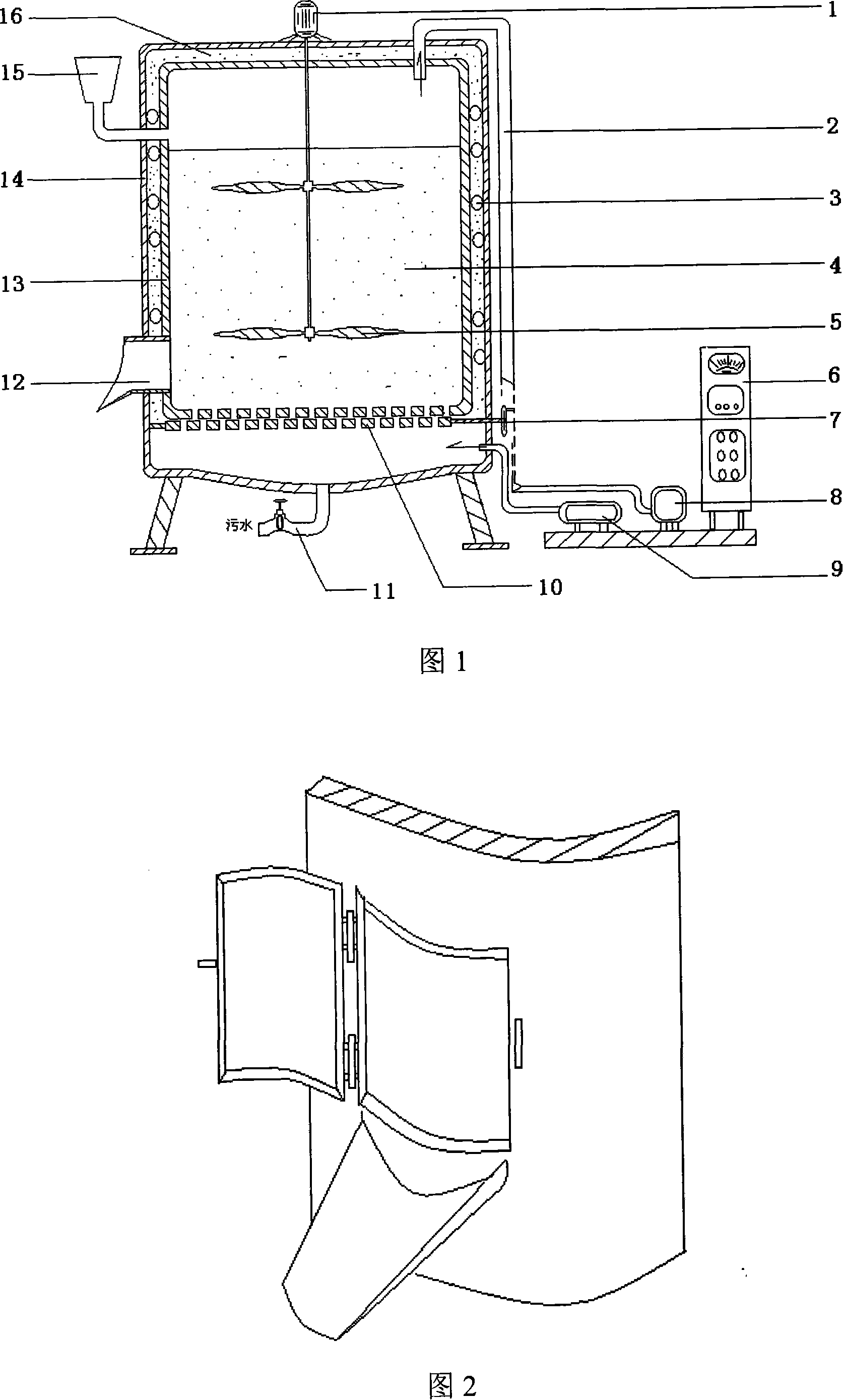

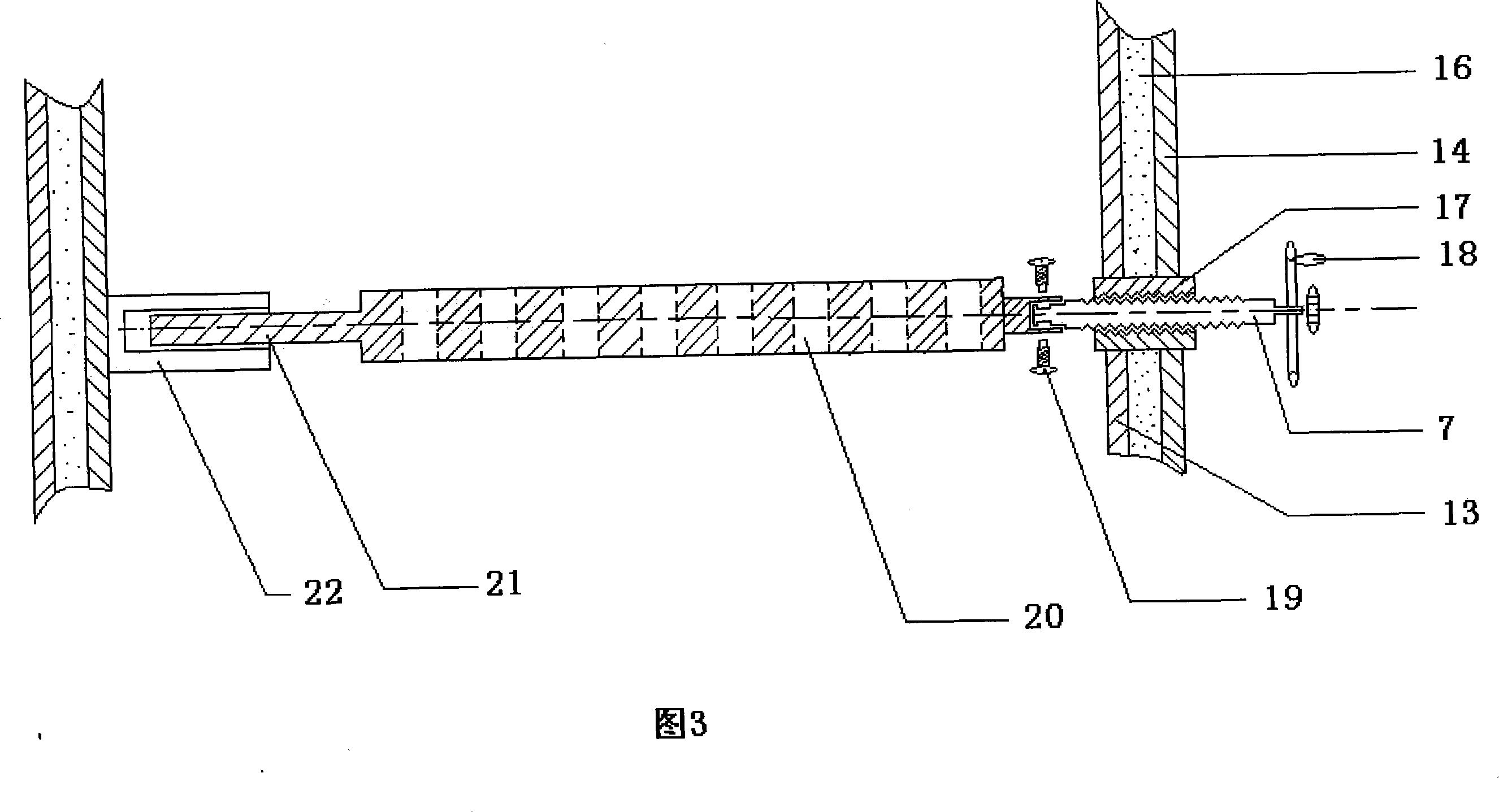

[0021] The sludge aerobic composting reactor is composed of an air inlet and outlet control system, a stirring system, a fermentation tank system, and a heating and temperature control system.

[0022] In the fermentation tank system, the inner tank is cylindrical with a radius of 500mm and a height of about 1700mm, and is made of steel plates with a thickness of 3mm; The top is 400mm, and the compost outlet is 50mm from the bottom of the inner tank. The air supply volume of the blower is controlled within the range of 30L / min. The motor is powered by a three-phase power supply. The total power of the electric furnace wire is 2000W, and the temperature of the heating layer is controlled at 45°C.

[0023] Take 500kg of sludge with an initial moisture content of 82.15%, add 0.5% sodium polyacrylate and 6.0% sawdust, pour it into the feed inlet, let it stand for 20 minutes, discharge 100kg of sewage, start the motor, and stir for 20 minutes. Stand for fermentation, start the vac...

Embodiment 2

[0025] The reactor structure of sludge aerobic composting is the same as that of Example 1. The air supply volume of the blower is controlled within the range of 30L / min. The motor is powered by a three-phase power supply. The total power of the electric furnace wire is 2000W, and the temperature of the heating layer is controlled at 55°C.

[0026] Take 500kg of sludge with an initial moisture content of 78.15%, add 0.8% sodium polyacrylate and 6.0% sawdust, pour it into the feed inlet, let it stand for 20 minutes, discharge 95kg of sewage, start the motor, and stir for 20 minutes. Stand still for fermentation, start the vacuum pump and blower once every 12 hours, and blow and pump air for 10 minutes each time; start the motor once every 24 hours for stirring, stirring for 10 minutes each time, after 10 days, composting ends, open the compost The discharge port of the tank, the discharge is packed into bags.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com