Device and method for testing rubber aggregate and cement stone interface binding intensity

A technology of rubber aggregates and interface bonding, which is applied in measuring devices, mechanical devices, and materials analysis, etc., can solve the problems of measuring and reflecting bonding properties, large errors, and low accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

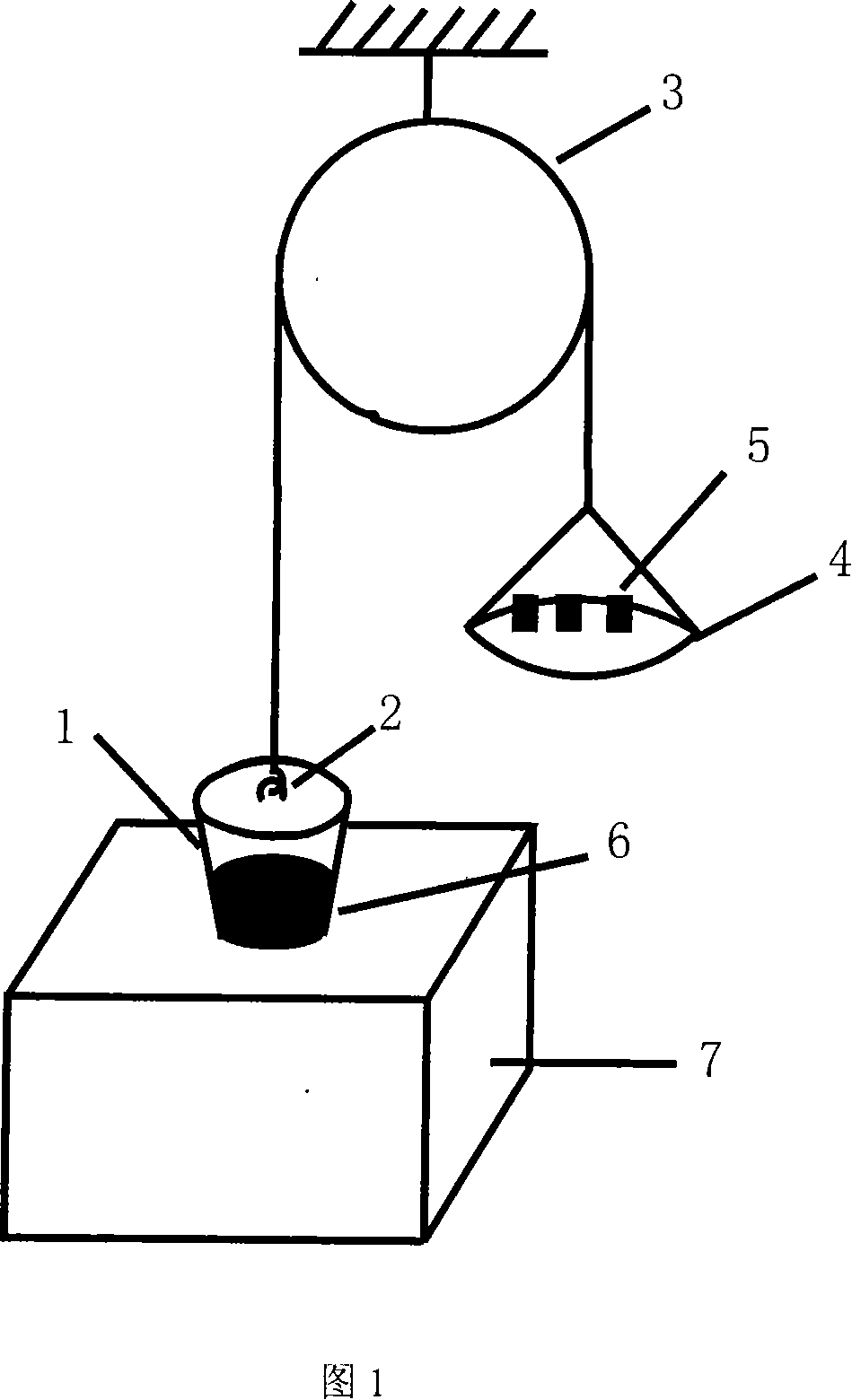

[0014] In order to test the effect of different rubber interface agents on improving the interface bond strength between cement concrete matrix and rubber aggregates, three different interface treatment agents were selected in the test: titanate coupling agent, styrene-acrylate-organic Silicon coupling agent copolymer, siloxane coupling agent, and in conjunction with the accompanying drawings, test according to the following steps.

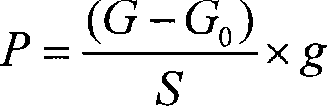

[0015] 1, make 4 frustum-shaped rubber blocks 1, the diameter of the small-diameter surface is 6cm, and the diameter of the large-diameter surface is 10cm, and the large-diameter surface of the truncated rubber block 1 is fixed with the pull ring 2 with epoxy resin adhesive, Polish the small-diameter surface and side of the truncated conical rubber block 1 with sandpaper, clean the small-diameter surface and the side with 1% NaOH aqueous solution, and apply the above-mentioned three kinds of coupling agents 6 on the small-diameter surfaces of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com