A making method for white LED chip

A white light-emitting and light-emitting chip technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems that the packaging solution is difficult to meet the requirements, the chip cannot be coated with phosphor powder, and the glue is difficult to withstand high temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

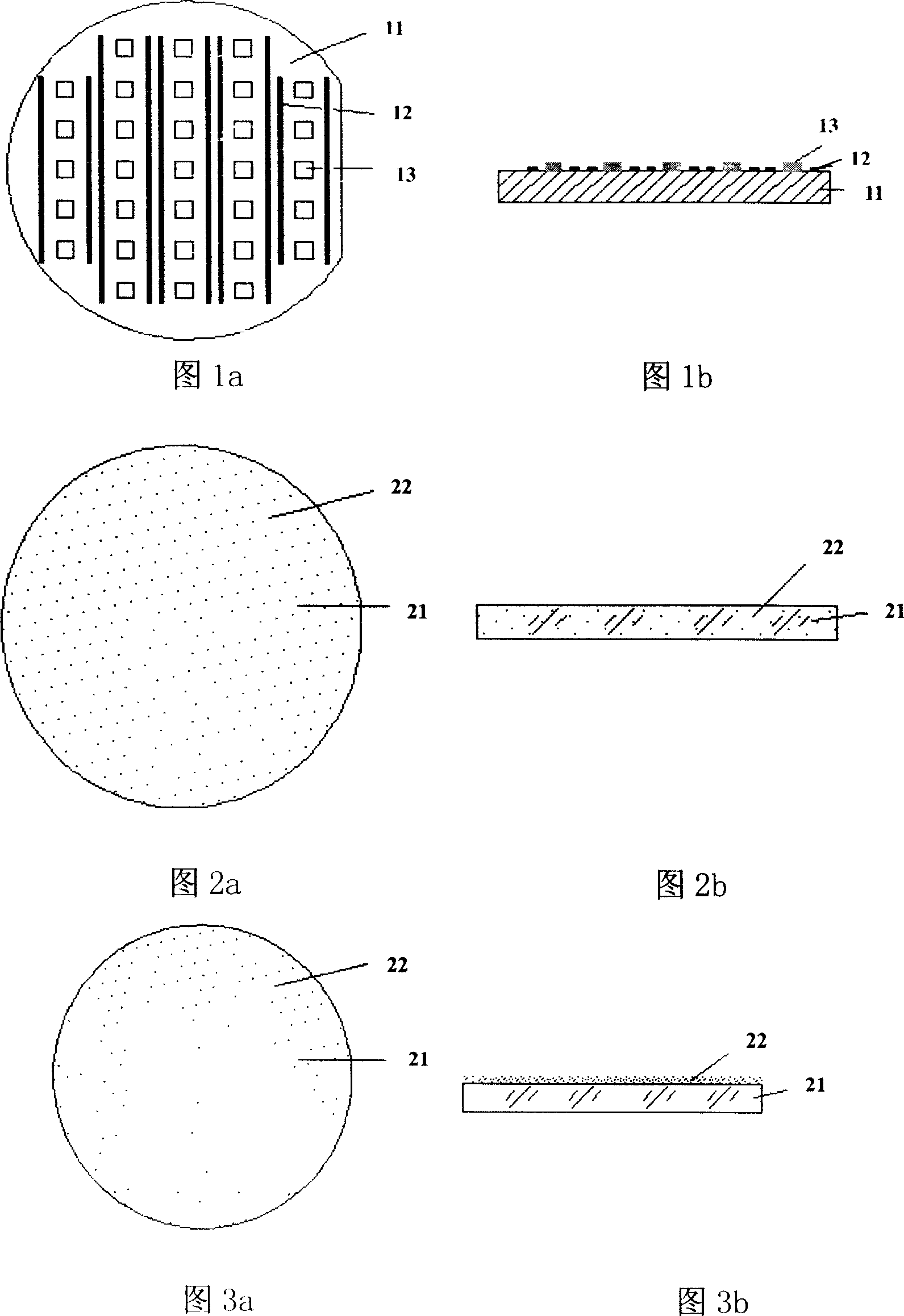

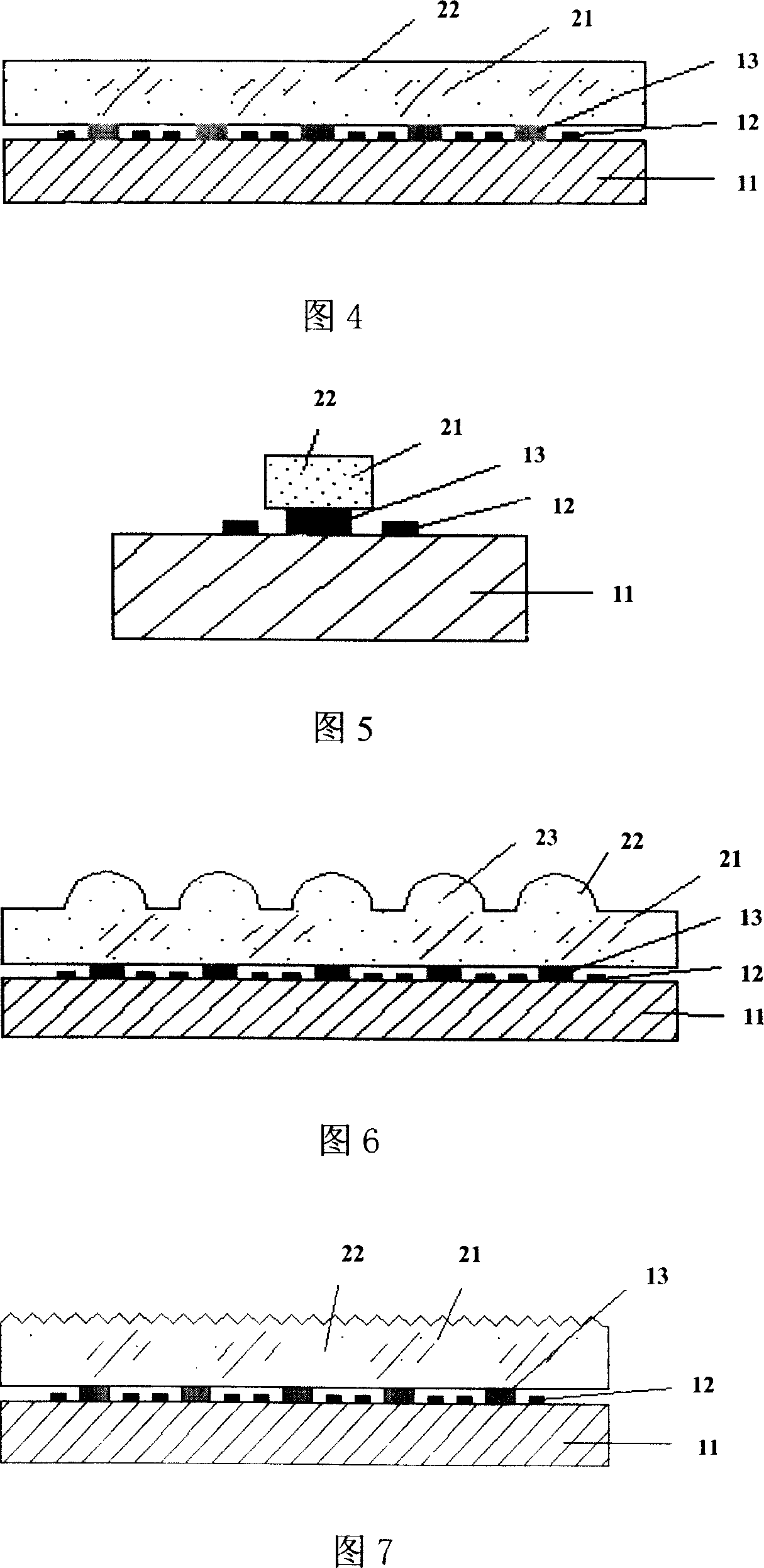

[0017] Referring to Fig. 1a and Fig. 1b, GaN blue LED chips 13 and electrodes 12 formed in an array on a silicon wafer substrate 11; referring to Fig. 2a and 2b, YAG yellow phosphor 22 is doped in a transparent glass substrate 21; 3a, FIG. 3b, YAG yellow phosphor powder 22 is deposited on the surface of the transparent substrate 21 by evaporation deposition or suspension coating process.

[0018] See Figure 4 and Figure 5 for the manufacturing process of white LED chips. The specific steps are as follows:

[0019] A. GaN blue light-emitting chips 13 and electrodes 12 are fabricated into an array on the silicon wafer substrate 11 by multi-layer epitaxy and photolithography, etching, and flip-chip methods;

[0020] B. Add aluminum yttrium garnet (YAG) yellow fluorescent powder 22 into the borosilicate glass raw material, mix it evenly, sinter and shape it, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com