Device with internal laser carving

A laser engraving and laser technology, which is applied in the direction of lasers, semiconductor lasers, laser welding equipment, etc., can solve the problems of large burst point size, slow engraving speed, large vibration and noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

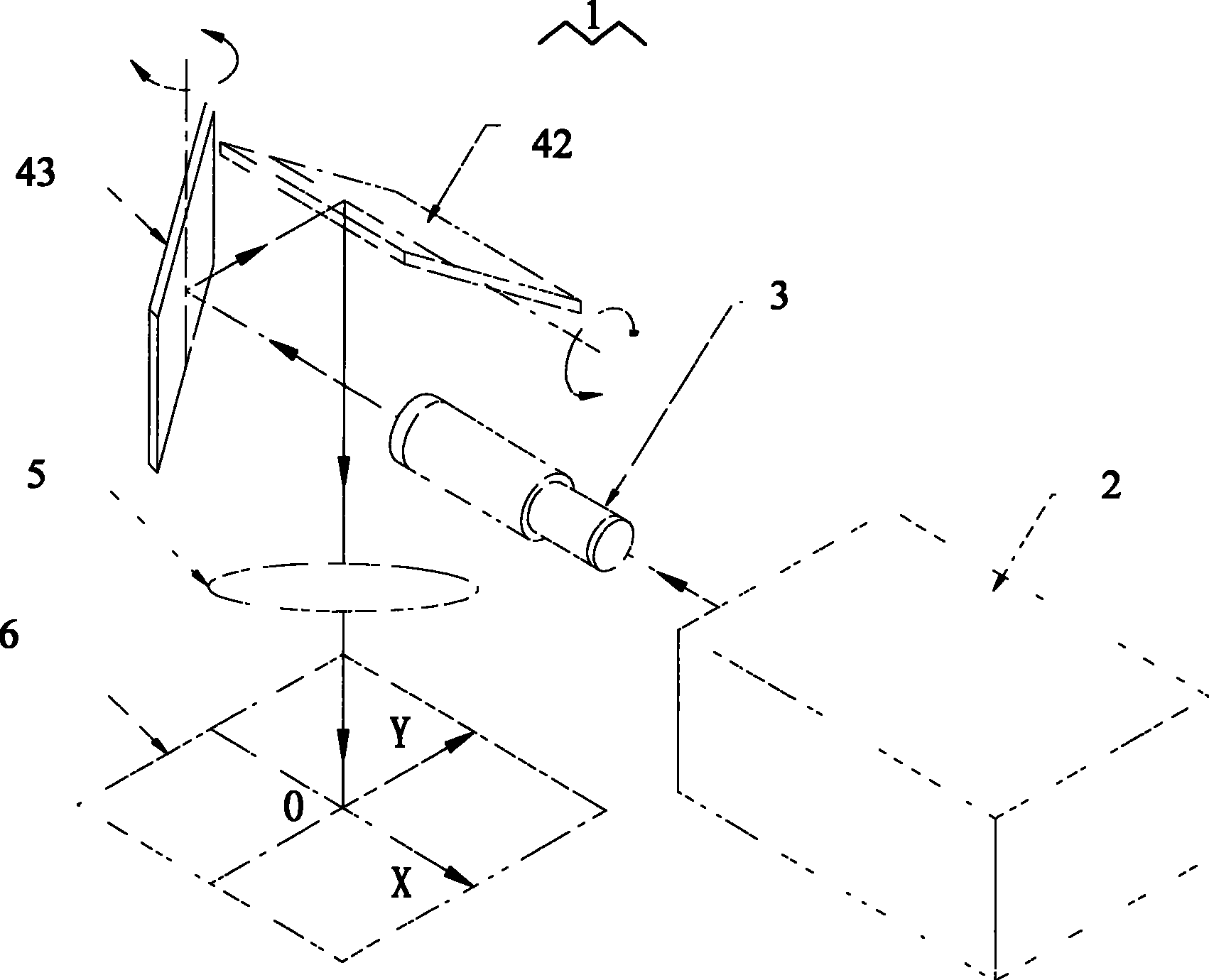

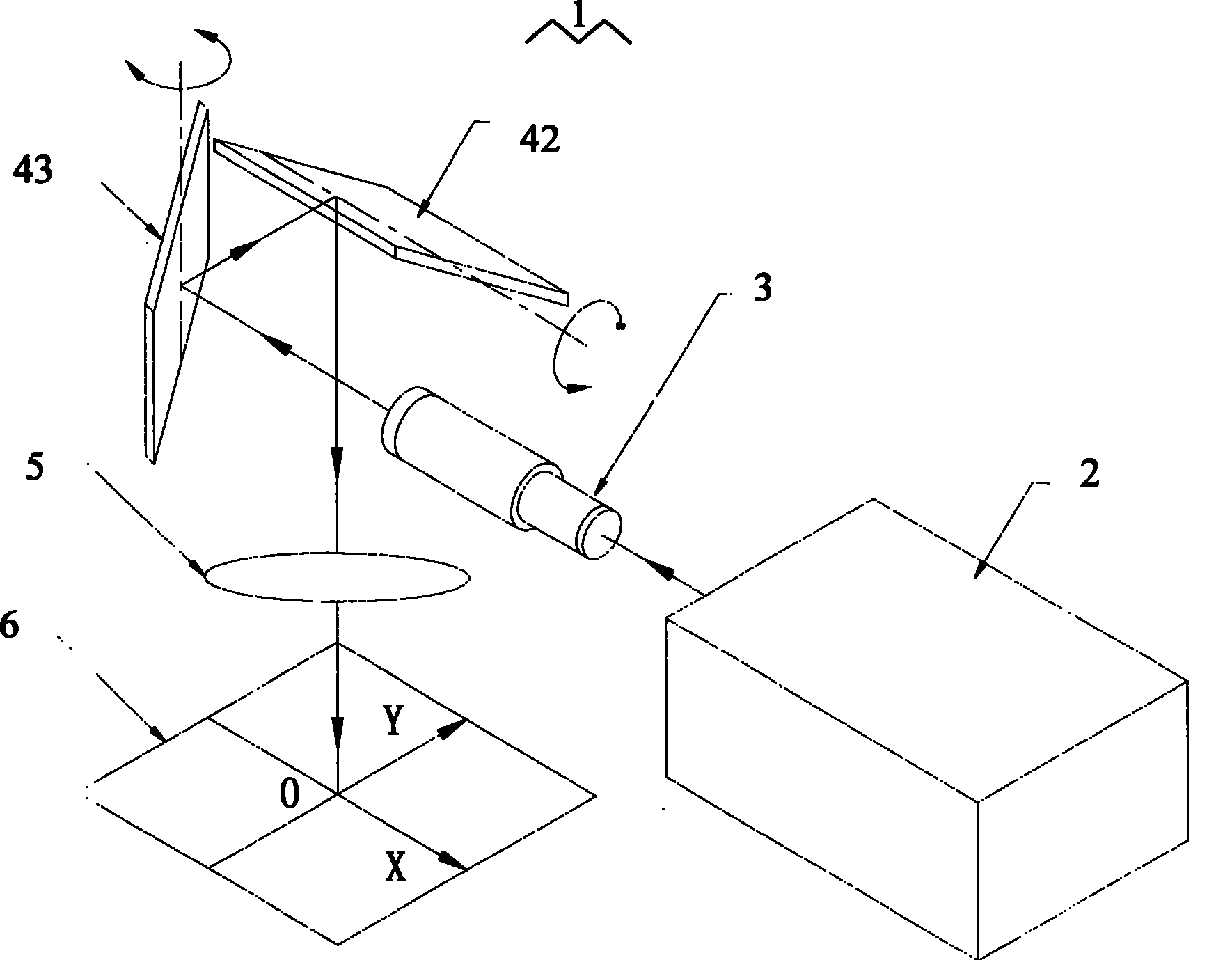

[0016] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an embodiment of the ultraviolet internal engraving device of the present invention. In this embodiment, the ultraviolet engraving device 1 includes: a laser generator 2 for generating an ultraviolet laser with a wavelength of 0.355 μm, a beam expander 3, a vibrating mirror scanner including at least two reflective vibrating mirrors 42, 43, a Focusing F-Theta lens 5 and a workbench 6 for carrying the material to be processed (not shown), wherein the reflective galvanometers 42, 43 can drive the laser beam to perform fast two-dimensional scanning in a predetermined plane under computer control , and the workbench 6 is driven by a one-dimensional transmission mechanism in a direction perpendicular to the predetermined plane under the control of the computer.

[0017] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com