Double-system sanitary sewage purifying biogas generating pit

A domestic sewage and dual-system technology, applied in biological sludge treatment, anaerobic digestion treatment, waste fuel, etc., can solve the problems of short service life, long construction period, affecting use, etc., and achieve long service life, convenient construction, The effect of compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

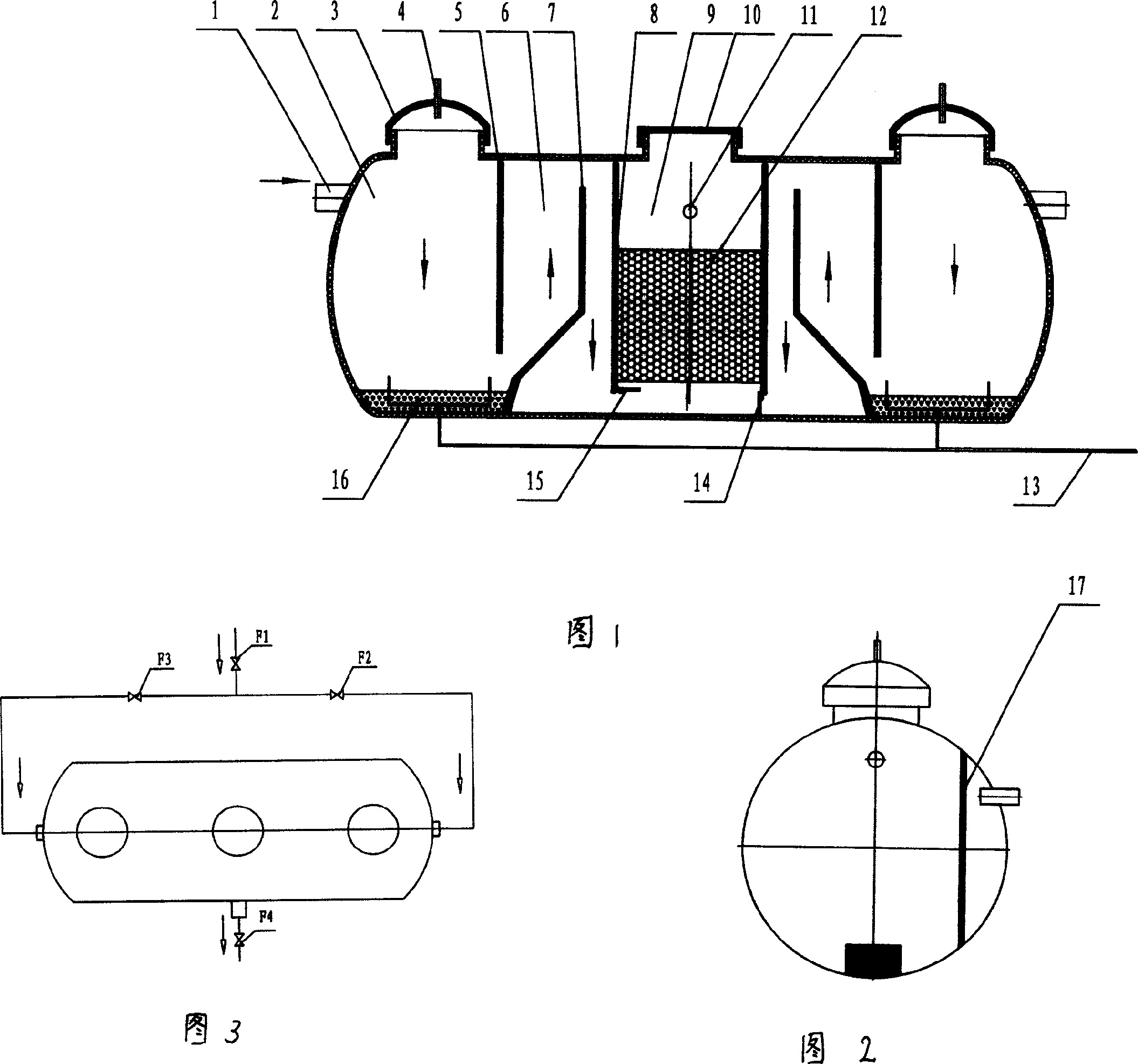

[0014] The present invention is made of glass fiber reinforced plastics, has an integral structure, and has a multi-stage self-flow and overflow anaerobic consumption system.

[0015] 1. As shown in the figure, the structure of the biogas digester consists of five parts: two primary anaerobic chambers (2), two secondary anaerobic chambers (6), two water inlets (1), and two water outlets (11) and a biological filtration chamber (9), wherein the primary anaerobic chamber (2), the secondary anaerobic chamber (6), and the biological filtration chamber (9) constitute a processing system.

[0016] 2. The primary anaerobic chamber (2) and the secondary anaerobic chamber (6) are separated by a primary partition (5), and the lower part of the primary partition (5) has a through hole, which is used as the digested biogas slurry to flow to the secondary Access to the anaerobic chamber (6). There is an anaerobic bacteria sludge layer (16) at the bottom of the primary anaerobic chamber (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com