Method for manufacturing optical glass, method for manufacturing precision press molding preform and method for manufacturing optical element

A manufacturing method and technology of optical glass, applied in glass forming, glass pressing, glass manufacturing equipment, etc., can solve the problems of corroding crucible, reducing the quality of optical glass, etc., and achieve the effect of reducing foreign matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] Example 1 (Manufacturing example of optical glass)

[0113] Phosphates, fluorides, and the like corresponding to the respective glass components were used as raw materials for the glass, and the raw materials were weighed and sufficiently mixed in order to obtain glasses having compositions No. 1 to No. 14 shown in Tables 1 to 3 .

[0114] The above blended raw materials were put into a carbon (graphite) crucible, melted at 850° C. for 1 hour while stirring, then rapidly cooled and pulverized to obtain a coarse cullet. In this melting step, nitrogen gas was continuously supplied into the carbon crucible, and the atmosphere was kept as a non-oxidizing atmosphere.

[0115] Next, 10 kg of the crude cullet was charged into a platinum crucible sealed with a lid, heated to 900° C., and stirred and melted. Thereafter, a very dry gas was introduced into a platinum crucible, and the molten glass was clarified at 1100° C. for 2 hours while maintaining the dry atmosphere. Example...

Embodiment 2

[0137] Example 2 (Manufacturing example of preform)

[0138] A conduit made of platinum alloy that adjusts the temperature of each molten glass formed from optical glass Nos. 1 to 14 obtained in Example 1 to a temperature range where the glass can flow out stably without devitrification at a constant flow rate Flow, by dripping, or by using a support to support the front end of the flow of molten glass and then rapidly lowering the support to separate the gob, separates gobs of molten glass at a target preform weight. Next, each of the obtained molten glass gobs is accommodated in a die having a gas outlet at the bottom, and gas is ejected from the gas outlet to form the glass gob while floating, thereby manufacturing optical glass No. 1 ~14 formed preforms for precision compression molding. By adjusting and setting the separation interval of the molten glass, the preform can be made into a spherical or oblate spherical shape. The weight of each obtained preform is precise...

Embodiment 3

[0144] Example 3 (Manufacturing example of optical element)

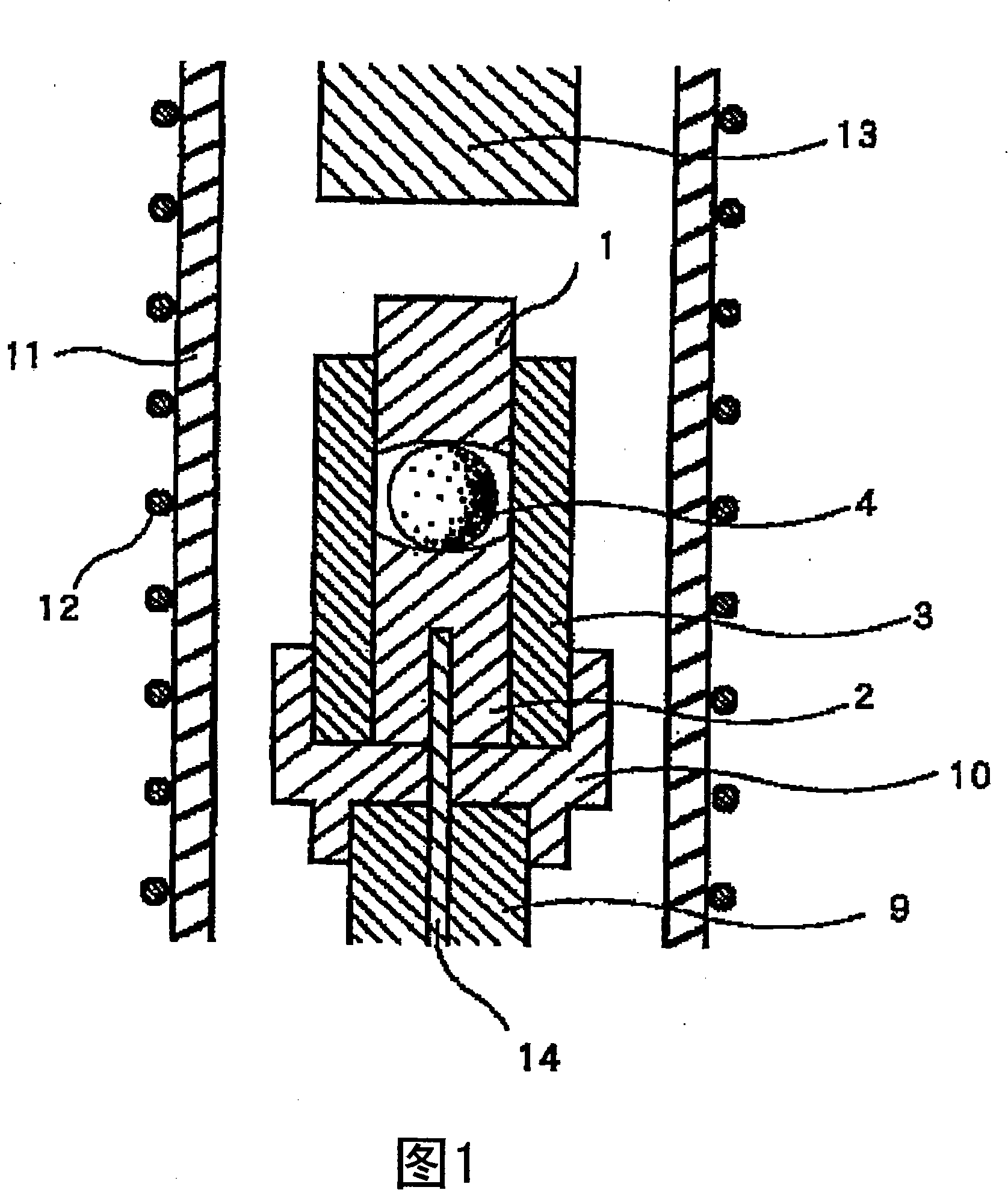

[0145] Preforms formed of optical glasses Nos. 1 to 14 obtained in Example 2 were subjected to precision press molding using the press apparatus shown in FIG. 1 to obtain aspheric lenses. Specifically, after the preform 4 is placed between the lower die 2 and the upper die 1 of the compression molding die consisting of the upper die 1, the lower die 2, and the body die 3, the inside of the quartz tube 11 is made into a nitrogen atmosphere, giving The heater 12 is energized to heat the inside of the quartz tube 11 . Set the temperature inside the press forming mold so that the formed glass shows 10 8 ~10 10 While maintaining the temperature at the viscosity of dPa·s, the push rod 13 is lowered to press the upper die 1, and the fixed preform is molded in the molding die. The molding pressure was 8 MPa, and the molding time was 30 seconds. After molding, remove the molding pressure, and keep the molded glass prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com