Method for producing acetylacetone copper

A technology of copper acetylacetonate and production method is applied in directions such as aldehyde/ketone chelate preparation, organic chemistry, etc., can solve problems such as low yield, complicated process, difficult separation, etc., and achieves reduction of production cost, process difficulty, and reduction of Effects of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Add 200Kg of ethanol to the reaction kettle as a solvent, add 100Kg of copper oxide powder under stirring, let it disperse evenly in the ethanol, then add 0.1% of the mass of copper oxide as a protonic acid catalyst, and then dropwise add 200Kg of acetylacetone, the system Spontaneously raise the temperature, keep the reaction at 40°C for 4 hours, cool, remove the solvent, and dry to obtain the product with a yield of 92%.

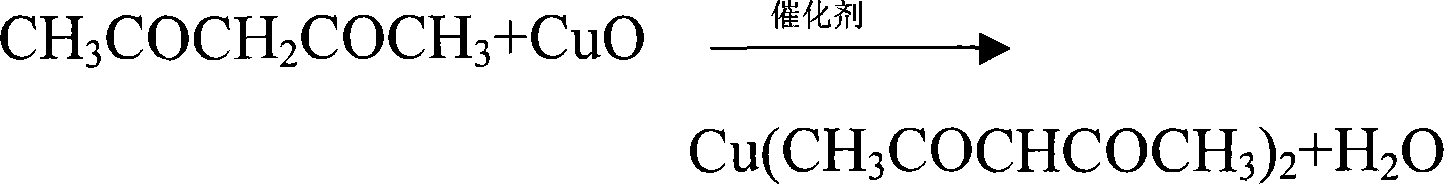

[0013] Its reaction formula is:

[0014]

Embodiment 2

[0016] Add 400Kg of ethanol as a solvent to a one-ton reactor, add 200Kg of copper oxide powder under stirring, let it disperse evenly in the ethanol, then add 2% of the mass of copper oxide as a protonic acid catalyst, and then dropwise add 400Kg of acetyl Acetone, the temperature of the system rises spontaneously, and the reaction is kept at 90°C for 2 hours, cooled, desolventized, and dried to obtain the product with a yield of 90%.

Embodiment 3

[0018] Add 300Kg of ethanol as a solvent to a one-ton reaction kettle, add 150Kg of copper oxide powder under stirring, let it disperse evenly in the ethanol, then add 1% of the mass of copper oxide as a protonic acid catalyst, and then dropwise add 300Kg of acetyl Acetone, the temperature of the system rises spontaneously, and the reaction is kept at 60°C for 3 hours, cooled, desolventized, and dried to obtain the product with a yield of 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com