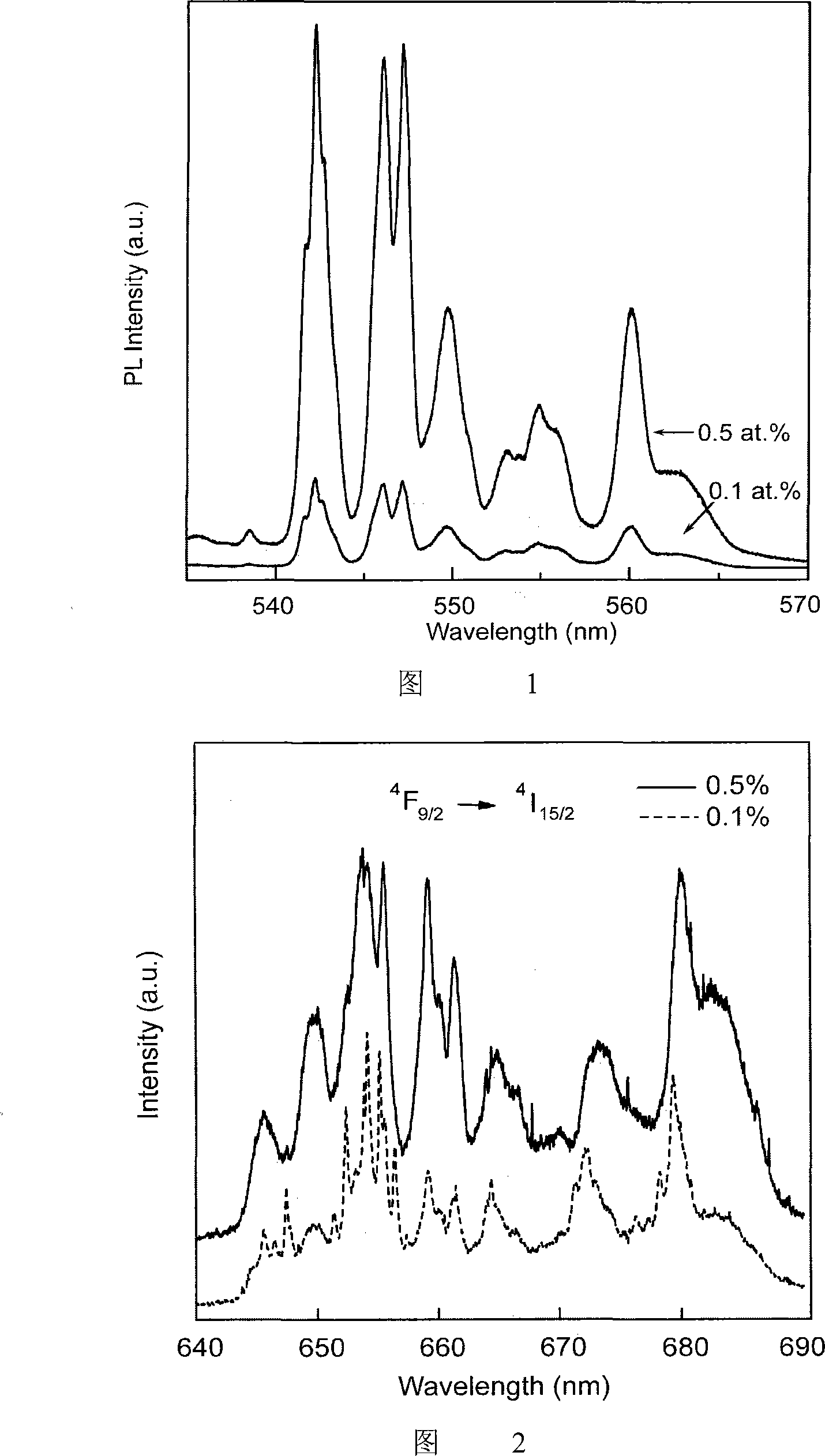

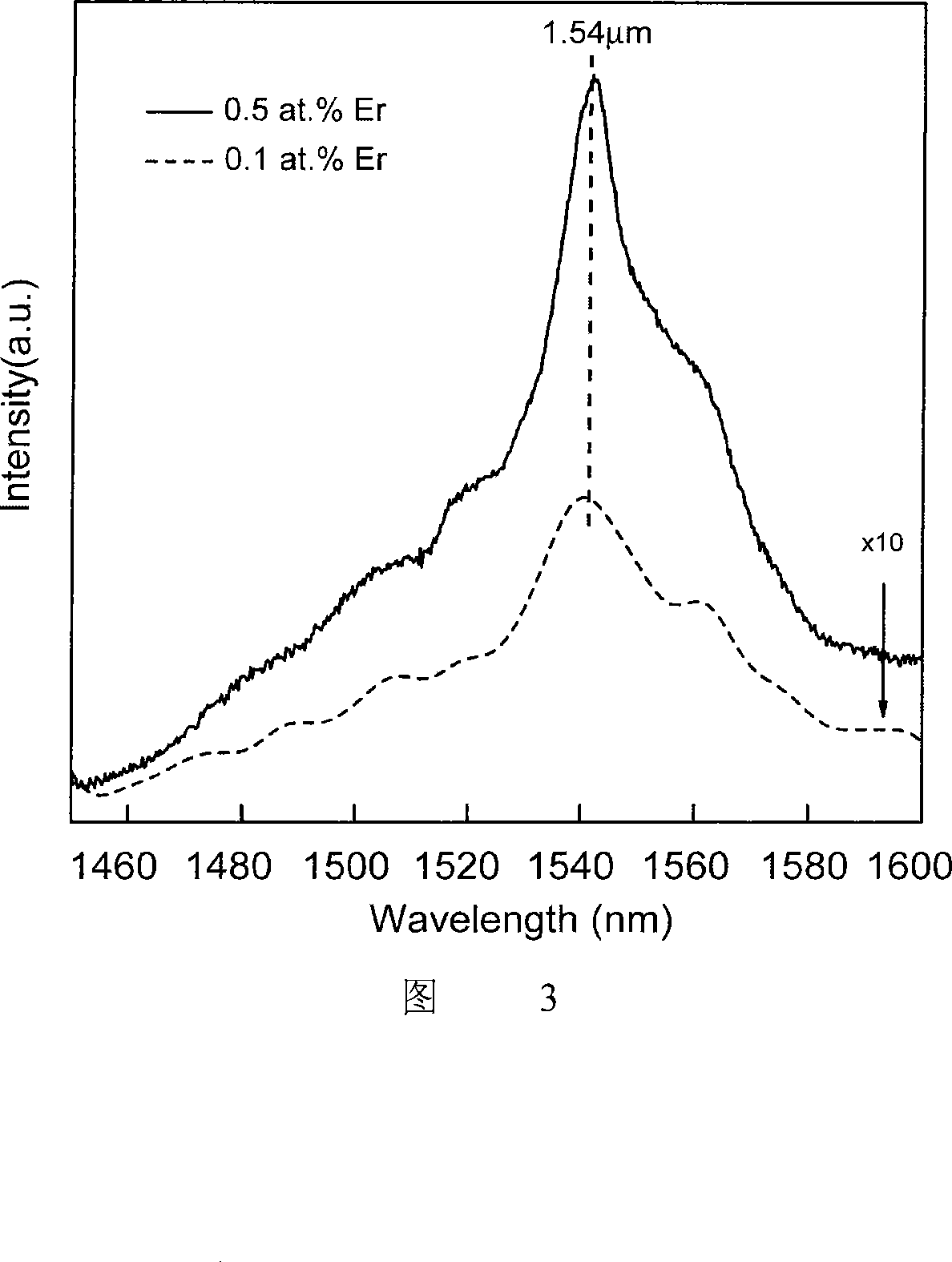

Visible and infrared luminescent C12A7 powder and preparation method thereof

A technology of infrared luminescence and dodecacalcium, which is applied in the field of materials and can solve problems affecting the luminous efficiency of rare earths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. get 7.878g (0.02100mol) purity to be 99.99% Al (NO 3 ) 3 powder and 1.998 g (0.01800 mol) of 99.95% pure CaCl 2 The raw materials are uniformly mixed in the water phase at the atomic level according to the chemical dosage ratio of 14:12;

[0021] 2. Add 0.04800g (0.000105mol) of Er(NO) with a purity of 99.99% 3 ) 3 The raw materials are doped according to the atomic molar ratio of erbium to aluminum at 0.5%, and the precipitant NH is added after uniform mixing 3 .H 2 O, to adjust the distance between cations. Slowly pour the mixed solution into the excess NH 3 .H 2 O in a beaker to ensure that each cation can be uniformly precipitated according to a certain ratio without causing phase separation, and 0.5% erbium-doped heptaaluminate dodecacalcium (12CaO 7Al 2 o 3 ) gel precursor.

[0022] 3. The obtained erbium-doped calcium heptaaluminate (12CaO·7Al 2 o 3 ) The gel precursor is dried and dehydrated at a temperature of 100°C;

[0023] 4. Put it in a high...

Embodiment 2

[0026] 1. get 7.787g (0.02100mol) purity to be 99.99% Al (NO 3 ) 3 powder and 1.998 g (0.01800 mol) of 99.95% pure CaCl 2 The raw materials are uniformly mixed in the water phase at the atomic level according to the chemical dosage ratio of 14:12;

[0027] 2. Add 0.009688g (0.000021mol) of 99.99% Er(NO 3 ) 3 The raw materials are doped according to the atomic molar ratio of erbium to aluminum at 0.1%, and the precipitant NH is added after uniform mixing 3 .H 2 O, to adjust the distance between cations. Slowly pour the mixed solution into the excess NH 3 .H 2 O in a beaker to ensure that each cation can be uniformly precipitated according to a certain ratio without causing phase separation, and 0.1% erbium-doped heptaaluminate dodecacalcium (12CaO 7Al 2 o 3 ) gel precursor.

[0028] 3. The obtained 0.1% erbium doped calcium heptaaluminate (12CaO·7Al 2 o 3 ) The gel precursor is dried and dehydrated at a temperature of 90°C;

[0029] 4. Put it in a high-temperature ...

Embodiment 3

[0032] Steps 1 and 2 are the same as in the embodiment, the drying and water removal time in step 3 is 120°C, the sintering temperature in step 4 is 1250°C, and the time is 6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com