Coal mine light concentration mash gas safety conveying method and conveying system

A low-concentration gas and transportation system technology, which is applied in the field of low-concentration gas safe transportation methods and transportation systems, can solve the problems of fine water mist failure, influence on atomization effect, small passing gap, etc., and achieve extremely easy formation and maintenance, The effect is easy to guarantee and guarantee the effect of water sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

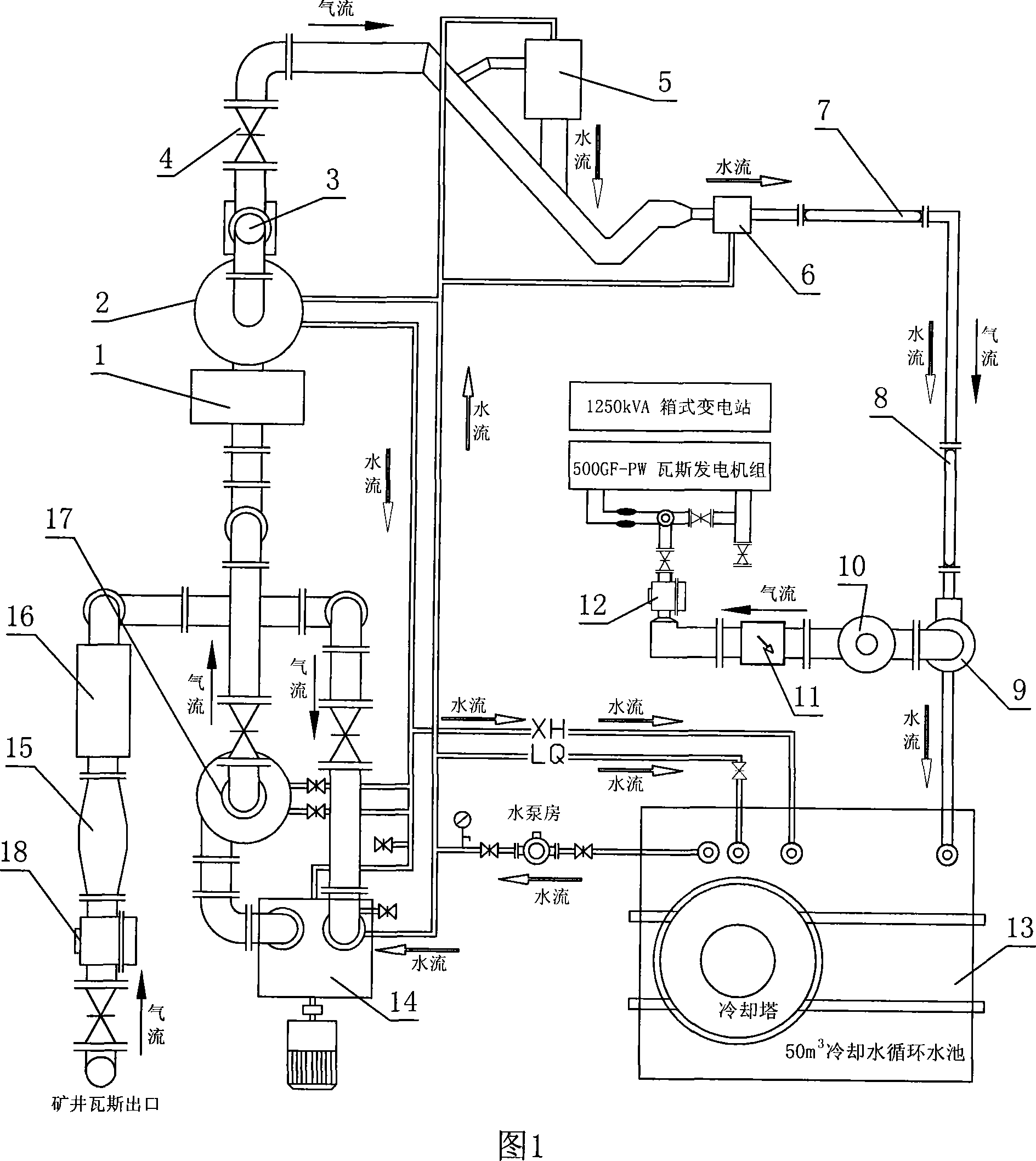

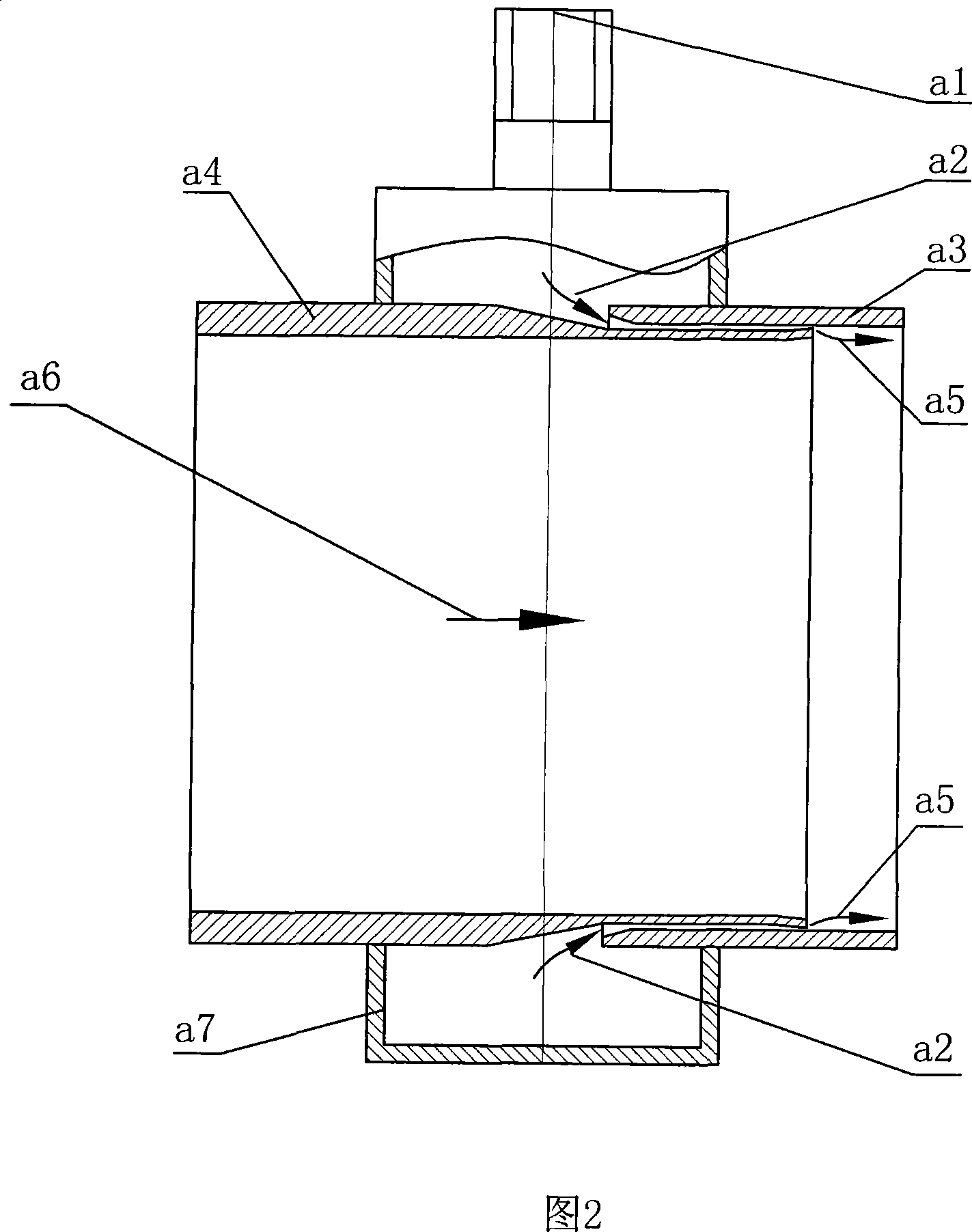

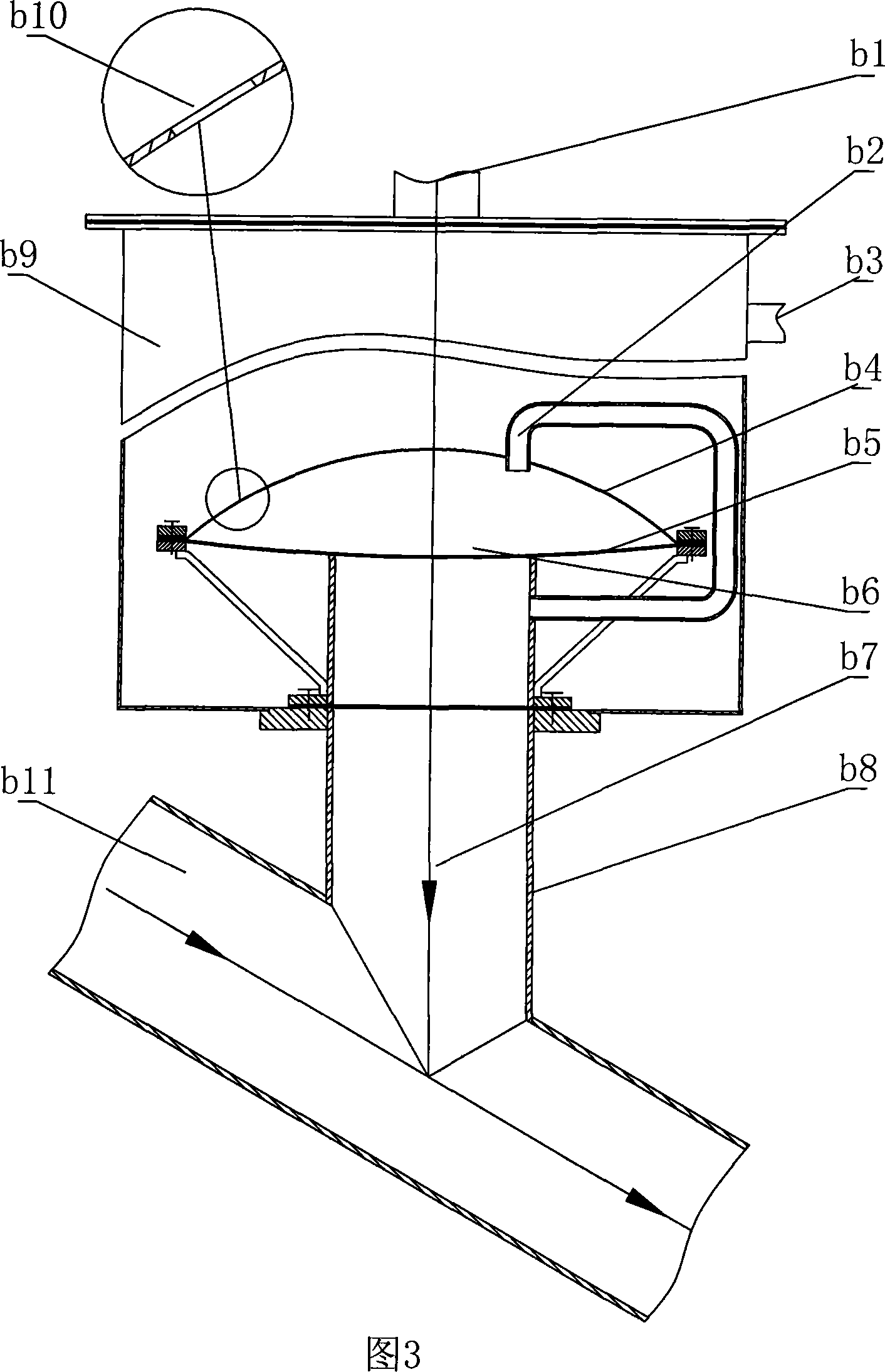

[0035]Referring to Fig. 1, the coal mine gas drainage power equipment adopts a water ring vacuum pump 14, and the mine gas outlet is connected to the inlet of the water ring vacuum pump 14 through a copper mesh flame arrester 15 and a front-stage flashback prevention device 16 arranged in series; The outlet of the vacuum pump 14 is connected to the positive pressure conveying main pipe of the gas utilization equipment, and the gas-water separator 17 in the input section, the explosion-proof and temperer-proof device 1 in the input section, and the voltage stabilizer in the input section are arranged in sequence in the initial section of the gas extraction pumping station. Diffuse device 2, gas emptying pipe 3, control valve 4, plunger flow device 5, and circulation device 6; in the low-concentration gas-water two-phase flow safety delivery pipeline, a transparent observation tube 7 in the front section is installed at the initial section, and a transparent observation tube 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com