Intelligent monitoring wind power box-type transformer station

A box-type substation, intelligent monitoring technology, applied in the direction of electrical components, energy industry, circuit devices, etc., can solve the problems of remote monitoring that cannot be found and processed in real time, slow information transmission, low work efficiency, etc., to achieve shortened time, Centralized management and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

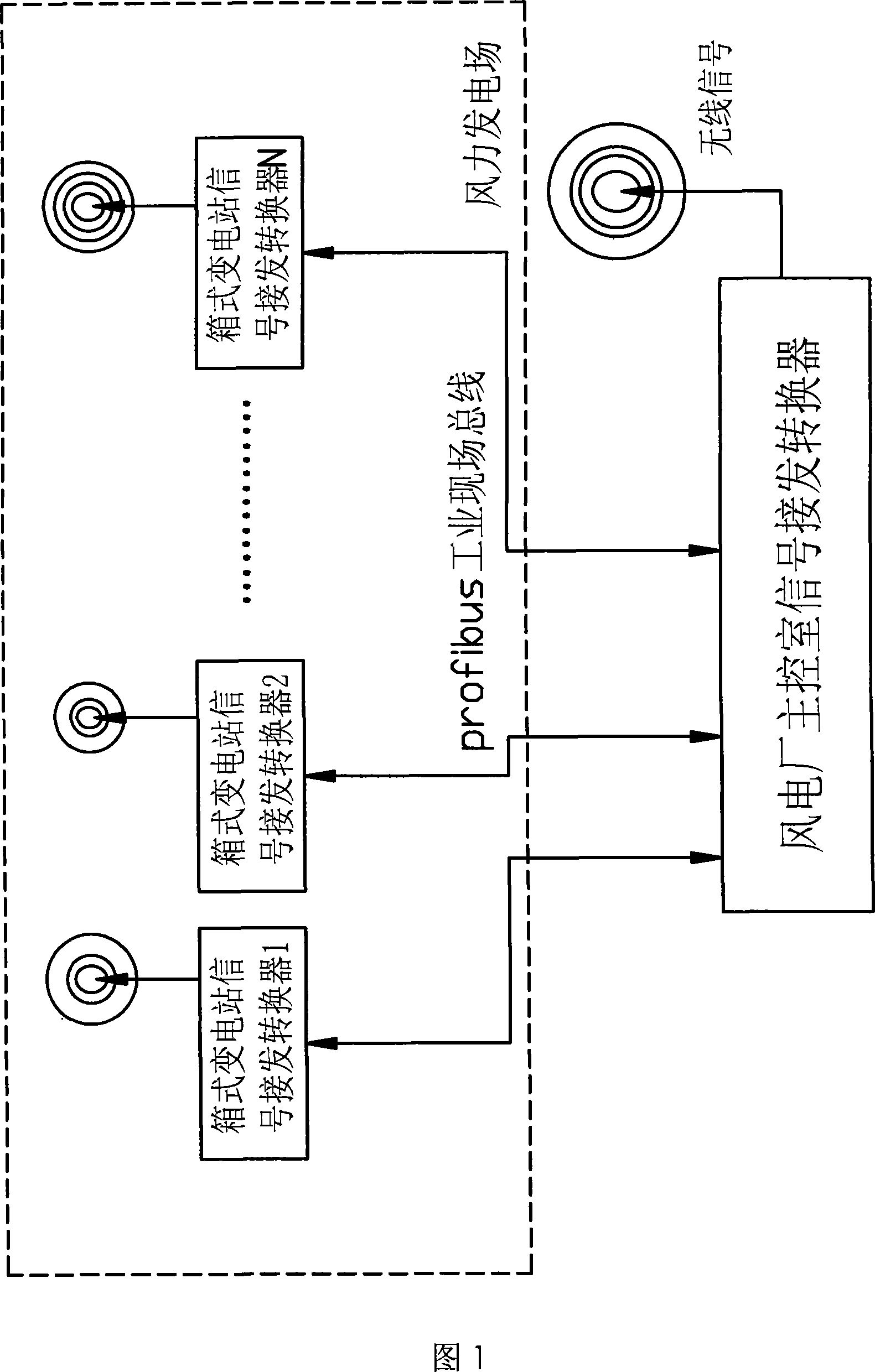

[0013] As shown in Figure 1, intelligent monitoring of wind power box-type substations, based on the basic technology of box-type substations, by setting signal converters in each box-type substation and the main control room of the wind power plant, the box-type substation of the wind farm and the main control room of the wind power plant The control room communicates with each other, so that the control signal and data collection information are transmitted between each box-type substation and the main control room of the wind power plant, realizing the functions of remote control, telemetry, remote communication, and remote adjustment, and self-diagnosing and monitoring the internal faults of the transformer. Troubleshooting for outgoing circuits.

[0014] The communication method adopts a wired or wireless communication method, or a combination of the two. The wired communication method is to set the profibus industrial field bus between each box-type substation and the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com