Preparation technique of organic silicon resin for high temperature resisting powder paint

A technology for powder coating and preparation process, which is applied in powder coatings, coatings and other directions, can solve the problems of high temperature resistance of powder coatings and high toxicity in the coating industry, and achieve the effects of protecting the environment, good economic benefits, and reducing the degree of gelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

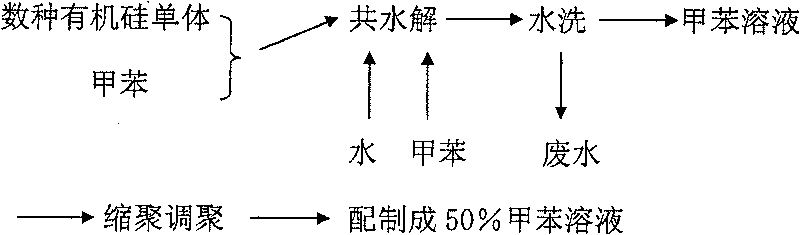

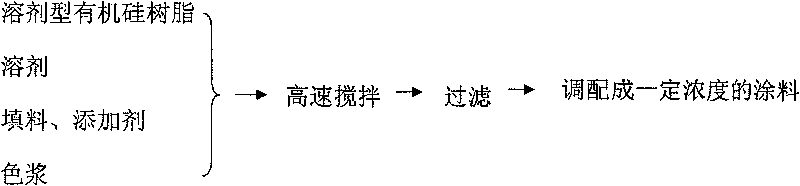

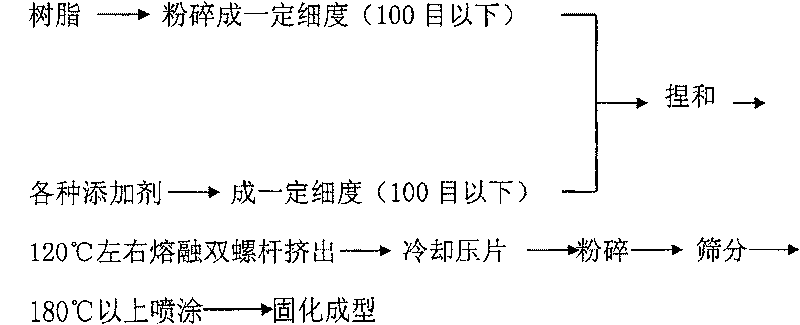

Method used

Image

Examples

Embodiment 1

[0024] a. Raw material composition ratio by mass

[0025] Dimethyldichlorosilane 99.9% purity 80 parts

[0026] Monomethyltrichlorosilane Purity>99% 120 parts

[0027] Diphenyldichlorosilane Purity>99% 120 parts

[0028] One-phenyltrichlorosilane Purity>99% 80 parts

[0029] Ester group-containing silicone coupling agent purity > 99% 120 parts

[0030] b. Fully mix the above-mentioned organosilicon monomers in proportion and add them into 600 parts of benzene solvent, add 1200 parts of methyl ethyl ketone and 600 parts of water, control the temperature at 5°C, carry out co-hydrolysis, and then add 1 part of catalyst ring Lead alkanoate telomerization polycondensation, add 140 parts of regulator epoxy-based silicone low molecular weight, reduce gel degree, remove solvent under vacuum negative pressure condition, cool and press tablet to obtain solid product.

[0031] The performance of the prepared silicone resin is basically good, the softening point and leveling property ...

Embodiment 2

[0033] a. Raw material composition ratio by mass

[0034] Dimethyldichlorosilane 99.9% purity 60 parts

[0035] Monomethyltrichlorosilane Purity>99% 110 parts

[0036] Diphenyldichlorosilane Purity>99% 110 parts

[0037] One-phenyltrichlorosilane Purity>99% 60 parts

[0038] Methyl vinyl dichlorosilane purity > 99% 65 parts

[0039] Methyl hydrodichlorosilane Purity>99% 60 parts

[0040] Hydroxyl-containing organosilicon coupling agent purity>99% 100 parts

[0041] b. Fully mix the above-mentioned organosilicon monomers in proportion, add them to 800 parts of benzene solvent, add 1800 parts of butyl ethyl ether and 900 parts of water, control the temperature at 10°C, carry out co-hydrolysis, and then add 0.8 parts of catalyst Platinum salt telomerization and polycondensation, adding 180 parts of regulator hydroxy silicone low molecular weight to reduce the degree of gelation, removing the solvent under vacuum and negative pressure, cooling and pressing to obtain a solid p...

Embodiment 3

[0044] a. Raw material composition ratio by mass

[0045] Dimethyldichlorosilane 99.9% purity 60 parts

[0046] Monomethyltrichlorosilane Purity>99% 120 parts

[0047] Diphenyldichlorosilane purity>99% 60 parts

[0048] One-phenyltrichlorosilane Purity>99% 110 parts

[0049] Epoxy-containing organosilicon coupling agent purity >99% 140 parts

[0050]b. Fully mix the above-mentioned organosilicon monomers in proportion and add them to 500 parts of benzene solvent, add 1800 parts of methyl ethyl ketone and 1000 parts of water, control the temperature below 10°C, carry out co-hydrolysis, and then add 1 part Catalyst zinc acetate for telomerization and polycondensation, add 140 parts of regulator hydroxyorganosilicon low molecular weight, reduce gel degree, remove solvent under vacuum negative pressure condition, cool and press tablet to obtain solid product.

[0051] The obtained silicone resin has good performance, but it has a slight gel, and the processing performance is g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com