Process for enriching copper and nickel in electroplating copper-nickel mixed waste water

A technology for mixing wastewater and electroplating copper, applied in the electrolysis process, electrolysis components, water/sewage treatment and other directions, can solve the problems of narrow application of ion exchange method, reduced resin processing capacity, environmental protection pressure, etc., to improve the regeneration rate and Effect of ion exchange processing capacity, prevention of resin contamination and poisoning, and reduction of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

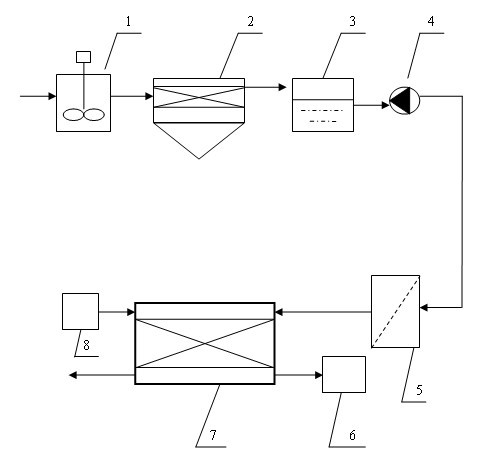

Image

Examples

Embodiment 1

[0022] A process for enriching copper-nickel from electroplating copper-nickel mixed wastewater, comprising the following steps:

[0023] ①Pretreatment: Adjust the pH value of the electroplating copper-nickel mixed wastewater to 4 in the neutralization tank, and then discharge it into the sedimentation tank to make Fe(OH) 3 Sedimentation and separation of flocs and solid impurities, removal of soluble oil and particulate impurities, and finally control of the oxidation-reduction potential of the wastewater to ≤30mV;

[0024] ② Ion exchange adsorption: The wastewater after the above pretreatment enters the ion exchange device, and the ion exchange resin absorbs and enriches copper and nickel until it is saturated;

[0025] ③ Ion exchange regeneration: connect the regeneration tank and ion exchange device, first use hydrochloric acid to regenerate and recover copper and nickel, and then use complexing agent citric acid and ethanol to regenerate and restore resin activity.

Embodiment 2

[0027] A process for enriching copper-nickel from electroplating copper-nickel mixed wastewater, comprising the following steps:

[0028] ①Pretreatment: Adjust the pH value of the electroplating copper-nickel mixed wastewater to 5 in the neutralization tank, and then discharge it into the sedimentation tank to make Fe(OH) 3 Sedimentation and separation of flocs and solid impurities, removal of soluble oil and particulate impurities, and finally control of the oxidation-reduction potential of the wastewater to ≤30mV;

[0029] ②Ion exchange adsorption step: the waste water after the above pretreatment enters the ion exchange device, and the ion exchange resin absorbs and enriches copper and nickel until saturated;

[0030] ③Ion exchange regeneration step: connect the regeneration tank and the ion exchange device, first use hydrochloric acid to regenerate and recover copper and nickel, and then use complexing agents citric acid, ethylenediaminetetraacetic acid, ethanol, and aceto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com