Method of forming a phase change memory and method for forming phase change layer

一种相变存储器、相变层的技术,应用在制造相变存储器,形成相变存储器中的相变层领域,能够解决GST层沉积温度增加等问题,达到尺寸减小、增加集成度、重置电流减小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will now be described more fully with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown. Here, the thicknesses and regions of layers shown in the drawings are exaggerated for clarity.

[0041] First, a method of manufacturing a phase change memory will be described. In addition, a method of manufacturing a phase change layer in a phase change memory will be described simultaneously.

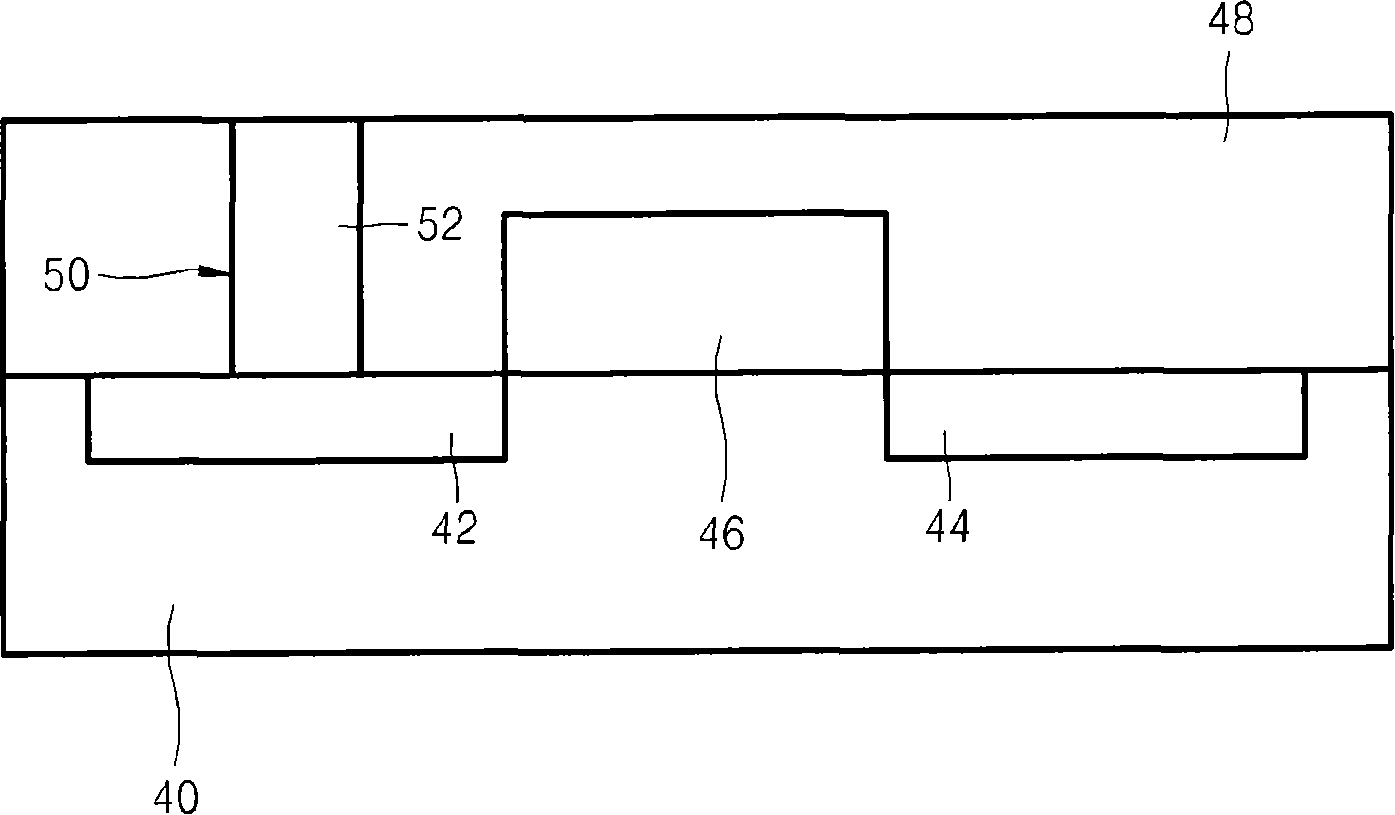

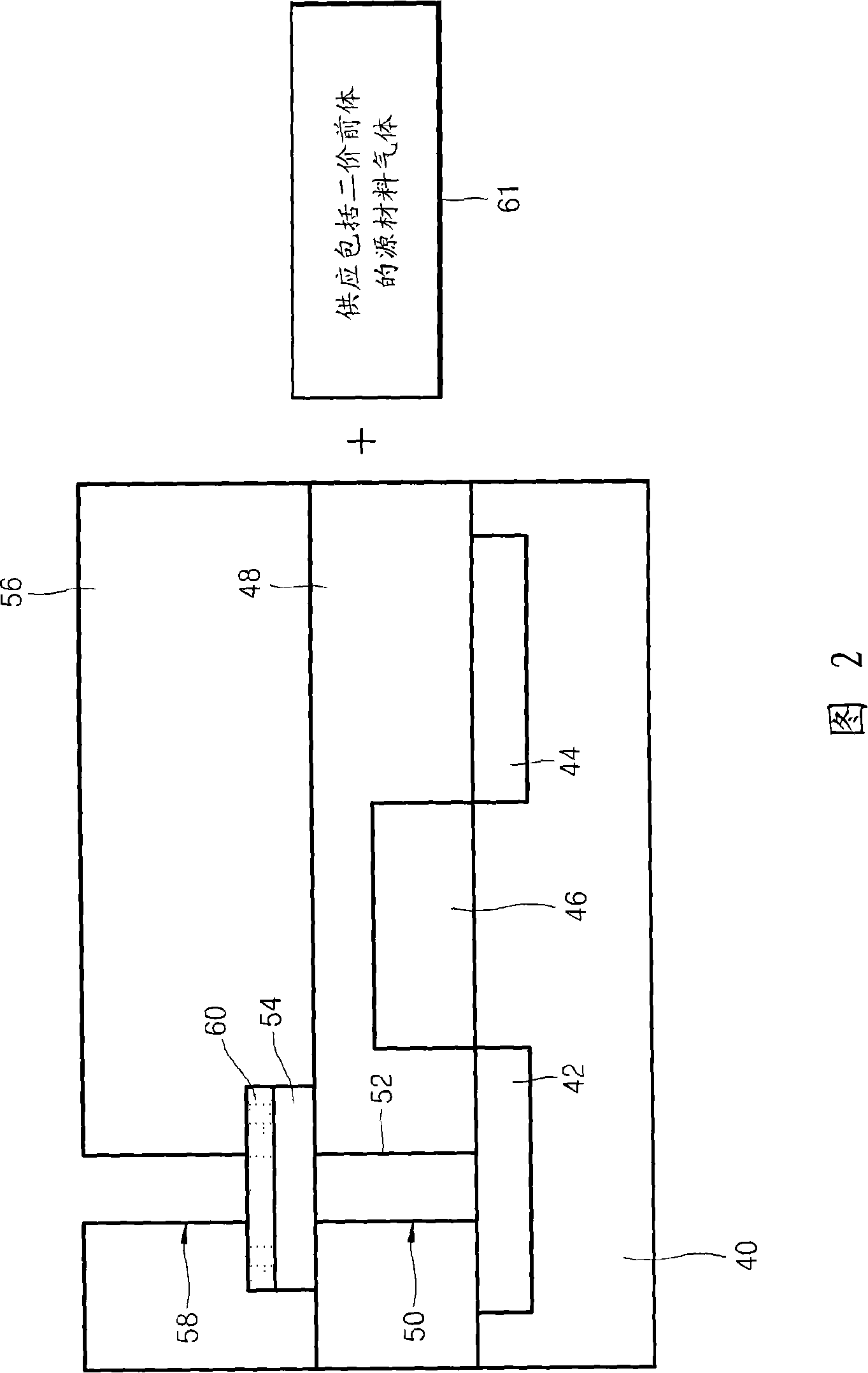

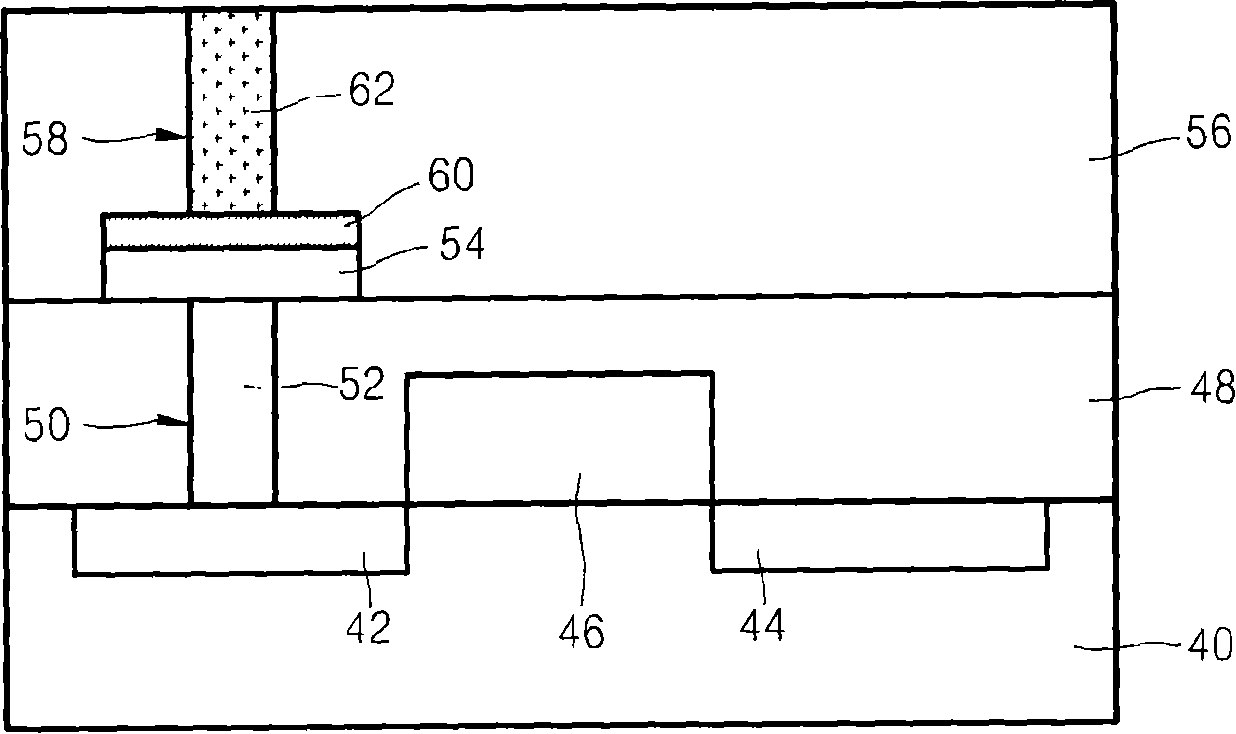

[0042] Figures 1 to 4 is a cross-sectional view illustrating a method of manufacturing a phase change memory according to an embodiment of the present invention. refer to figure 1 A gate stack 46 is formed in a predetermined region of an active region defined by a device isolation layer (not shown) on the p-type or n-type substrate 40 . The gate stack 46 includes a gate insulating layer and a gate electrode. The first impurity region 42 and the second impurity region 44 are formed between the device isolation layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com