Formula of pre-mixed fodder for high effective well-fattened meat lamb

A premix, lamb technology, applied in the application, animal feed, animal feed and other directions, can solve the problems of affecting the nutrient digestion of feed, effective deposition of metabolism, lack of feed modulation technology, affecting the feed conversion rate and lamb shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

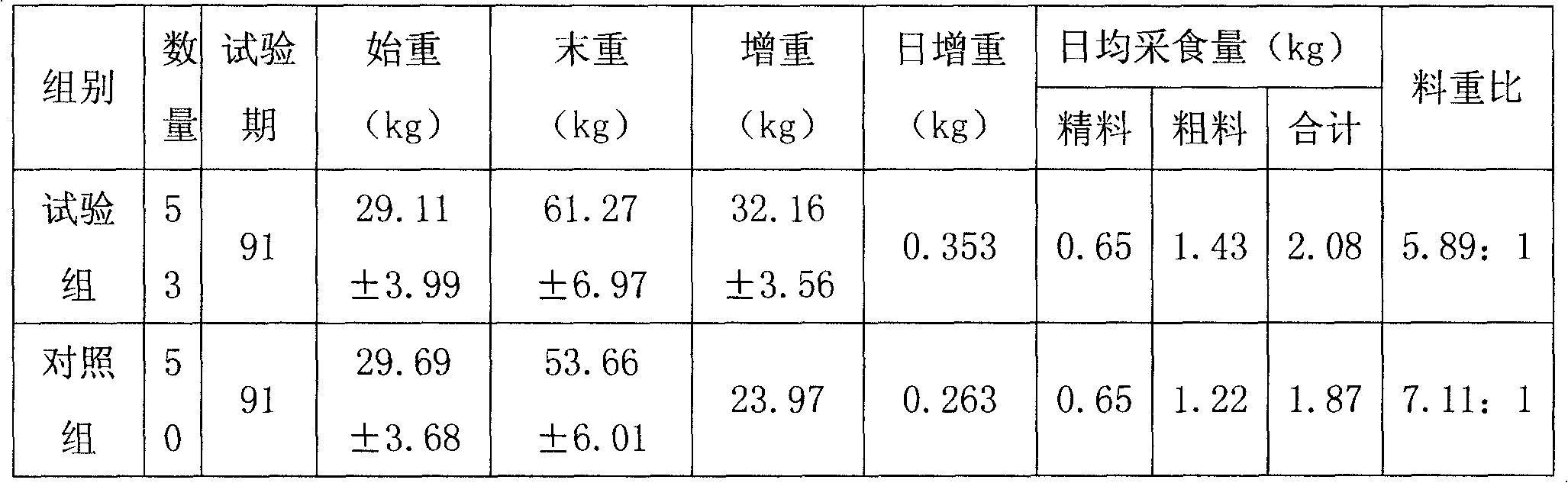

Examples

Embodiment approach 1

[0028] Embodiment 1: Lamb fattening premix for meat is prepared from raw materials with the following weight ratios:

[0029] MnSO4 ·H 2 O 2.3kg, FeSO 4 ·7H 2 O 3.0kg, CuSO 4 ·5H 2 O 1.0kg, KI 1.2kg, ZnO 1.0kg, Na 2 SeO 3 ·5H 2 O 0.6kg, CoCl 2 ·6H 2 O 0.53kg, MgO 12.0kg, NaHCO 3 17.0kg, Na 2 SO 4 17.0kg, vitamin A 0.035kg, vitamin D 0.019kg, vitamin E 0.18kg, stone powder 22.0kg, Ca(HPO 4 ) 2 35.0kg, monensin 0.16kg, bone meal 4.8kg, urea 2.0kg, hawthorn 176.0kg, malt 150.0kg, tangerine peel 80.0kg, Polygonum multiflorum 80.0kg, Schisandra 60.0kg, Chuanxiong 114.0kg, black soybean 150.0kg, secondary powder 70.176kg .

[0030] The above-mentioned raw materials are respectively crushed and directly mixed uniformly to obtain 1000 kg of premix. When in use, the premix is added according to 5% of the total weight of the concentrate ration after all mixing.

Embodiment approach 2

[0031] Embodiment 2: The lamb fattening premix for meat is prepared by the following solid raw materials in parts by weight:

[0032] MnSO 4 ·H 2 O 2.1kg, FeSO 4 ·7H 2 O 2.8kg, CuSO 4 ·5H 2 O 0.9kg, KI 1.1kg, ZnO 0.9kg, Na 2 SeO 3 ·5H 2 O 0.55kg, CoCl 2 ·6H 2 O 0.5kg, MgO 11.5kg, NaHCO 3 16.5kg, Na 2 SO 4 16.5kg, vitamin A 0.03kg, vitamin D 0.017kg, vitamin E 0.16kg, stone powder 21.5kg, Ca(HPO 4 ) 2 34.5kg, monensin 0.15kg, bone meal 4.7kg, urea 1.9kg, hawthorn 170kg, malt 145kg, tangerine peel 75kg, fleece-flower root 75kg, schisandra 55kg, chuanxiong 110kg, black soybean 145kg, sub-flour 70.8kg.

[0033] The above-mentioned raw materials are directly mixed evenly after crushing respectively to obtain 1000kg premix. When in use, the premix is added according to 5% of the total weight of the concentrate ration after all mixing.

Embodiment approach 3

[0034] Embodiment 3: The lamb fattening premix for meat is prepared from raw materials with the following weight ratios:

[0035] MnSO 4 ·H 2 O 2.5kg, FeSO 4 ·7H 2 O 3.2kg, CuSO 4 ·5H 2 O 1.1kg, KI 1.3kg, ZnO 1.1kg, Na 2 SeO 3 ·5H 2 O 0.65kg, CoCl 2 ·6H 2 O 0.56kg, MgO 12.5kg, NaHCO 3 17.5kg, Na 2 SO 4 17.5kg, vitamin A 0.04kg, vitamin D 0.021kg, vitamin E 0.2kg, stone powder 23.5kg, Ca(HPO 4 ) 2 35.3kg, monensin 0.17kg, bone powder 4.9kg, urea 2.1kg, hawthorn 170kg, malt 145kg, tangerine peel 80kg, Polygonum multiflorum 80kg, Schisandra 60kg, Chuanxiong 120kg, black soybean 145kg, sub-flour 30.66kg.

[0036] The above-mentioned raw materials are crushed respectively and directly mixed uniformly to obtain 1000 kg of premix. When in use, the premix is added according to 5% of the total weight of the concentrate ration after all mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com