Outside thermal insulation construction method for anchoring and sticking composite thermal insulation plate outside wall

A technology of external thermal insulation and composite thermal insulation of external walls, applied in covering/lining, building, building structure, etc., can solve the problems of high thermal conductivity of thermal insulation layer, environmental pollution, easy cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

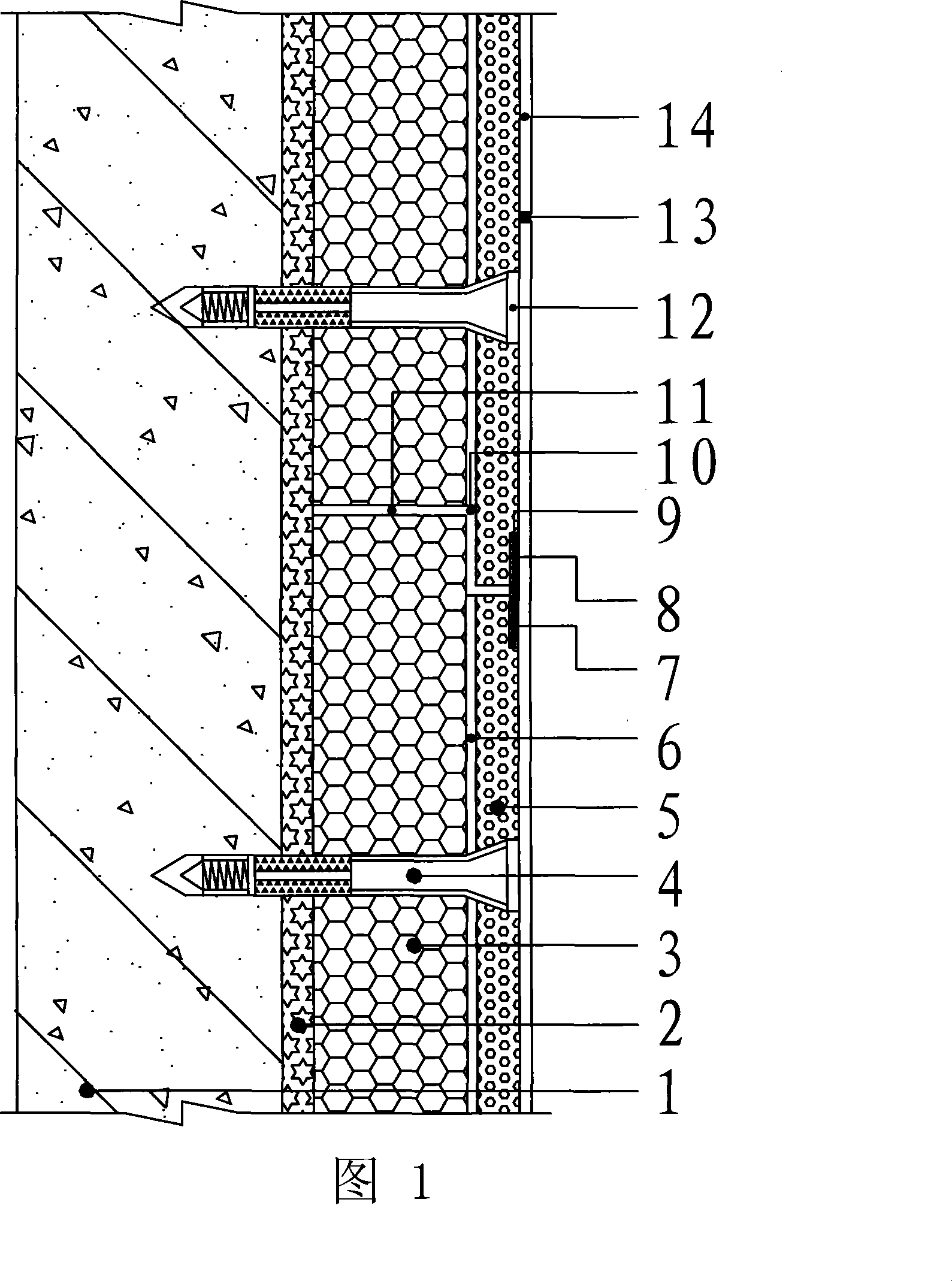

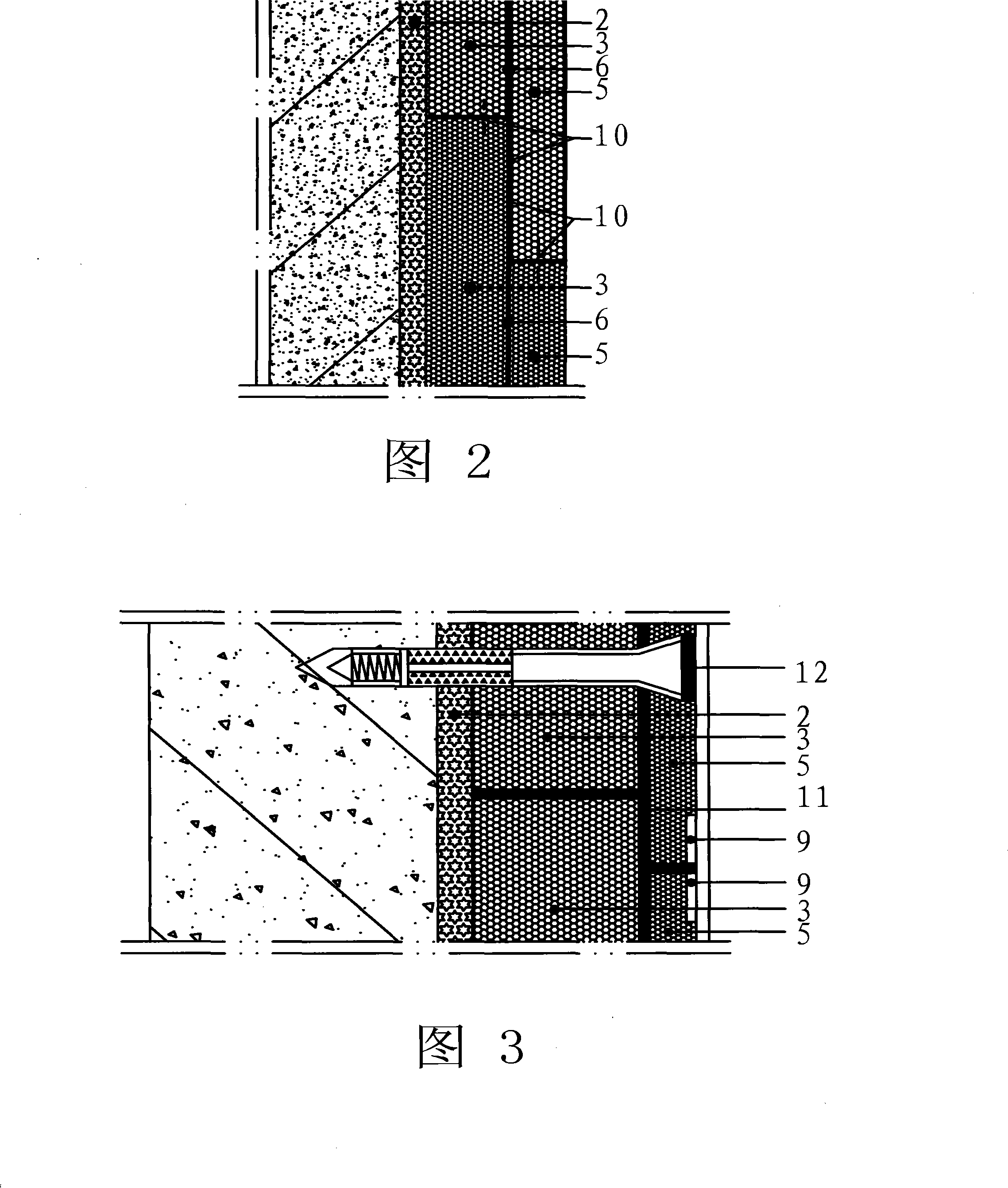

[0005] It contains microfoam glue 2, insulation board 3, TOX nylon sleeve steel nail 4, cement-based environmentally friendly lightweight board 5, adhesive 6, flexible anti-crack putty 7, alkali-resistant mesh cloth 8, groove 9, L-shaped groove 10. Styrofoam 11. Flexible anti-crack putty of the same material 12. Weather-resistant silicone sealant 13. Finishing 14. First, use adhesive 6 to bond the thermal insulation board 3 and the cement environmental protection lightweight board 5 into a composite thermal insulation board with an L-shaped tongue-and-groove 10 falcon connection structure. And use TOX nylon sleeve steel nail 4 to anchor. Then form an anchor, bond and composite connection to achieve long-term safety and high reliability of external wall insulation. The L-shaped tongue and groove 10 butt joints of the composite insulation board are sealed with foam glue 11, and there are pre-processed grooves 9 with a depth of 1.5-2.0mm and a width of 50-80mm on the surfaces of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com