Focusing leveling measuring method and device

A technology for focusing, leveling, and measuring systems, applied in the field of optical measurement, to achieve the effects of reducing errors, stabilizing the measurement system, and improving measurement resolution and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

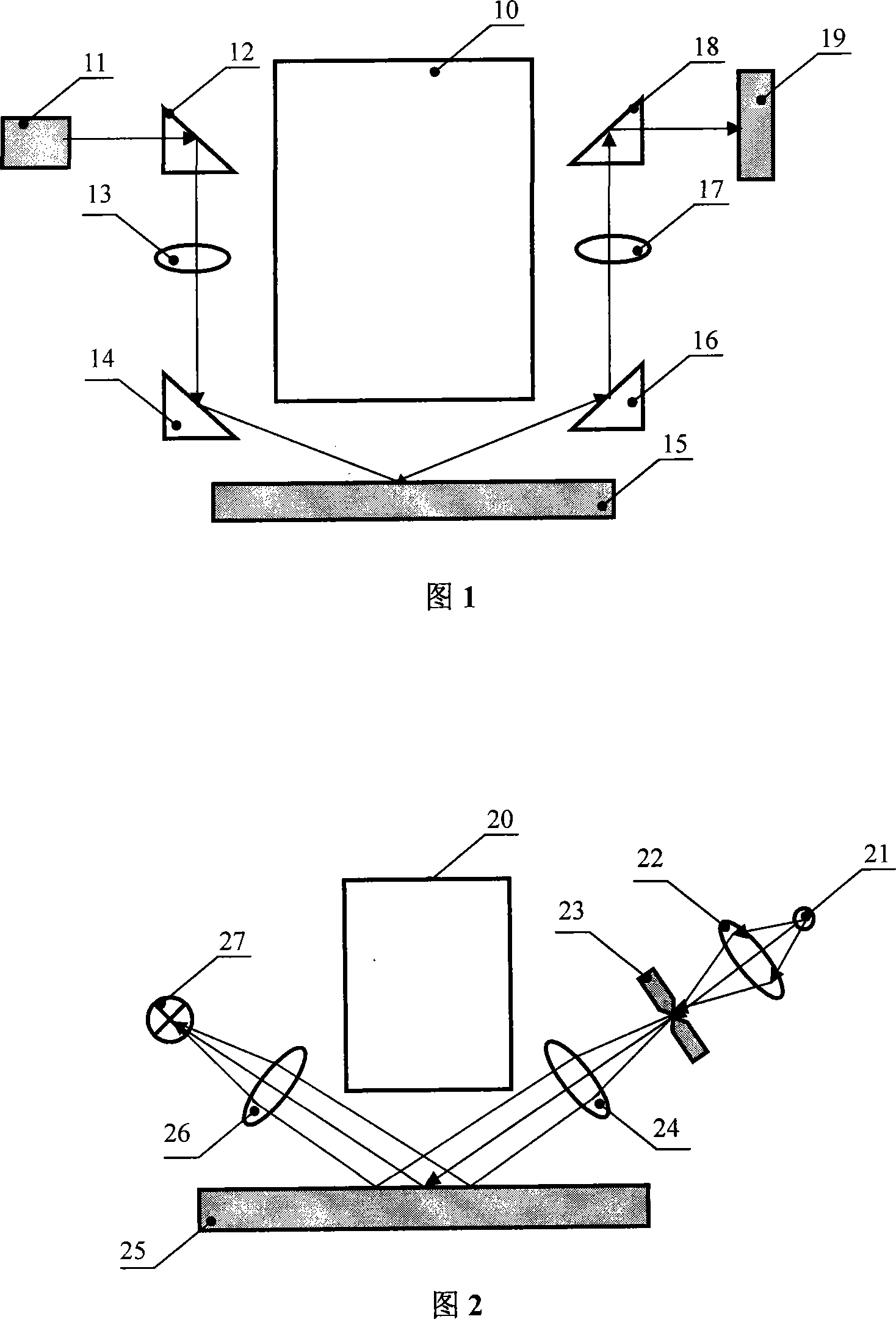

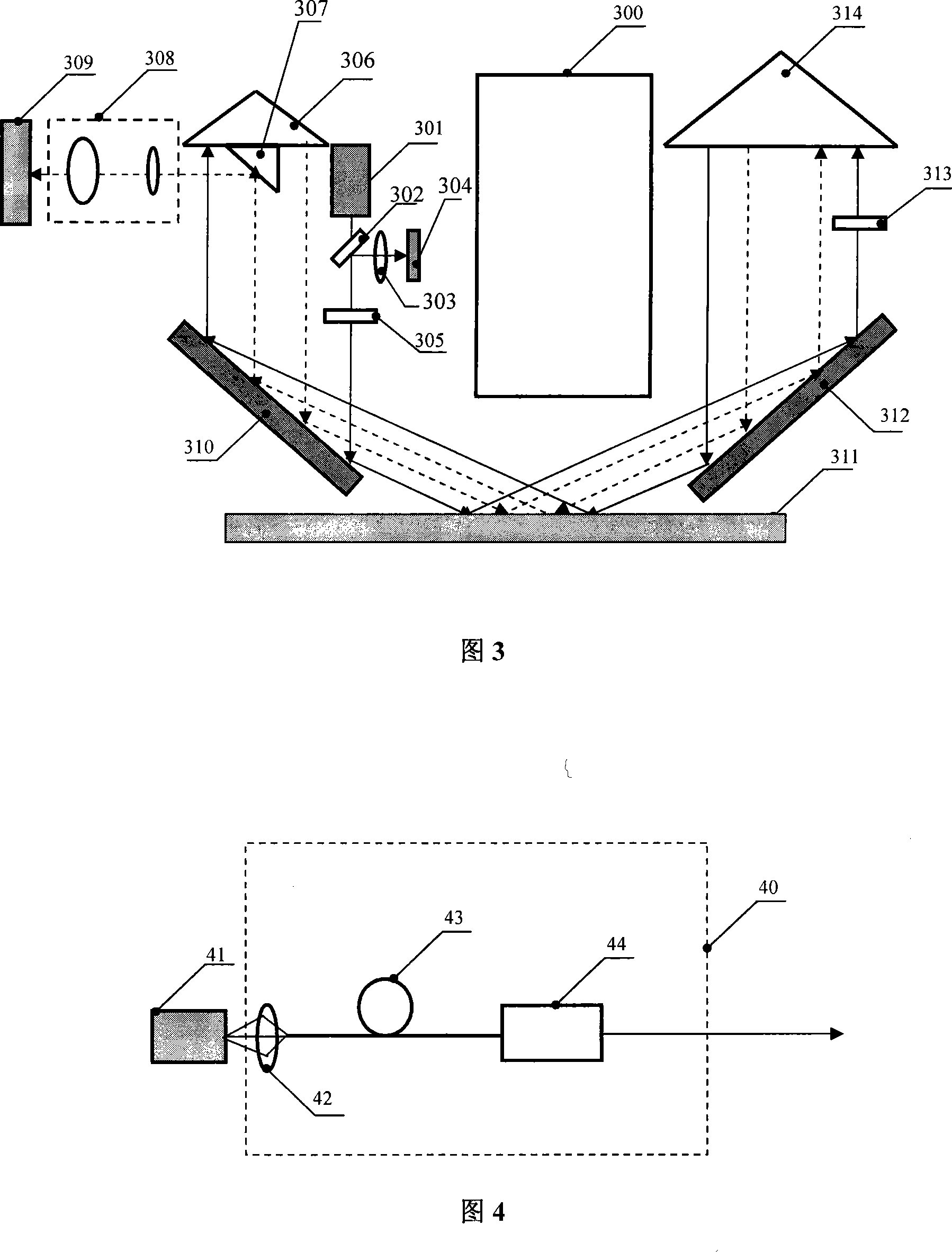

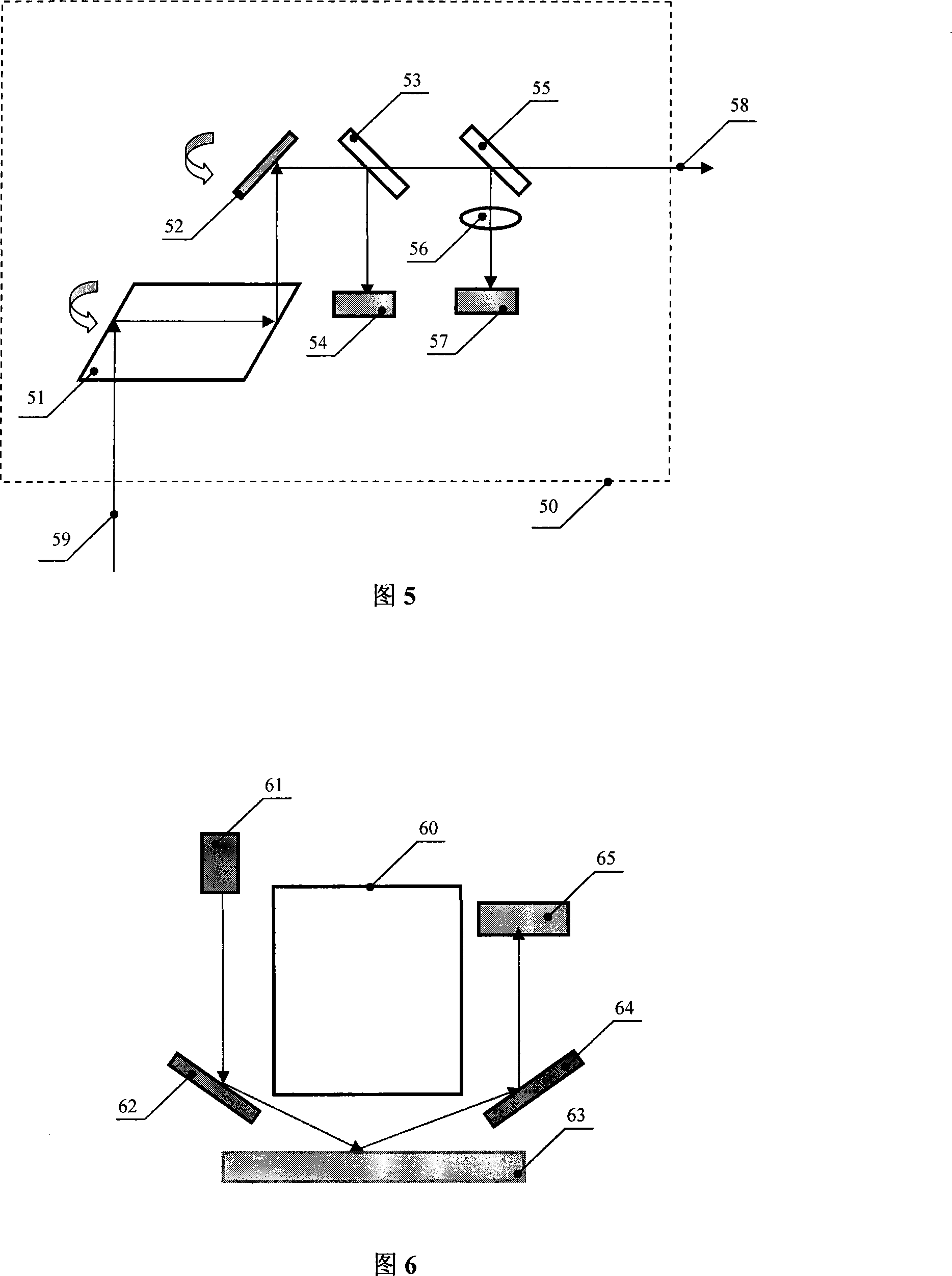

[0043] Further illustrate the present invention below in conjunction with accompanying drawing.

[0044] As shown in FIG. 3 , it is a schematic structural diagram of a focusing and leveling system of a photolithography machine according to the present invention. Each component module of the optical system of the present invention will be described one by one in conjunction with FIG. 3 below. The light source collimation module 301 emits highly stable collimated laser light, which becomes linearly polarized light through the polarization beam splitter 302, passes through the λ / 4 wave plate 305, passes through the plane mirror 310, and is incident on the surface 311 of the silicon wafer to be measured. The light is reflected from the silicon wafer surface 311 and the plane mirror 312 to the half mirror 313 . The half-reflector 313 splits the light into two parts (reflected light and transmitted light). The reflected light returns in reverse along the original optical path, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com