Composite frozen confections

A technology for freezing sweets and sweets, which is applied in the directions of frozen sweets, baked goods, food preparation, etc., and can solve the problems such as the loss of brittleness of baked food particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

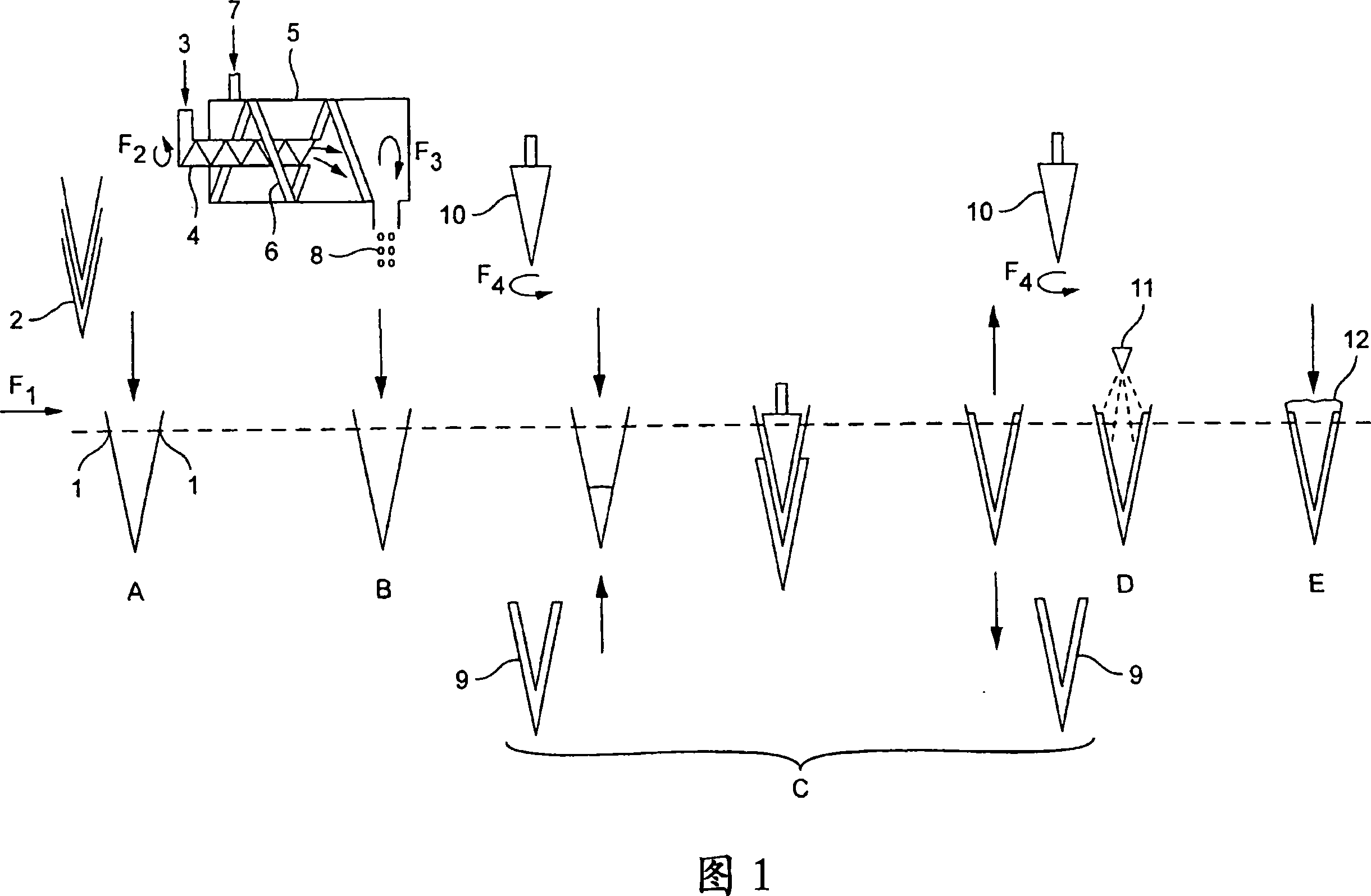

Method used

Image

Examples

example 1

[0052] 1) Preparation of improved biscuit products

[0053] Breakfast cereal flakes (CPW Golden Graham obtained from CPW Factory, Rumilly, France) measuring 6 x 6 mm were subdivided into particles with an average diameter of 0.5-6 mm. The resulting granular material has a particle size as measured by sieving: >90% of the particles are retained on a 0.7 mm sieve and <10% are retained on a 4.8 mm sieve. In stage B, 70 parts of the granulated breakfast cereal at ambient temperature are mixed with 30 parts of various essential oils based on various essential oils such as shea butter, mistletoe butter, mango oil, sal and A cocoa butter equivalent blend of fractionated and unhydrogenated palm oil supplied by Aarhus Oliefabfik A / S, Denmark under the name Illexao 30-61 (Illexao is a registered trademark). The above components are continuously mixed at 45°C in a rapid mixing device Parimix (Parimix is a registered trademark), wherein a continuous supply of dry crispy particles is ...

example 2

[0057] Preparation of composite frozen desserts using cereal cones

[0058] The cone prepared in Example 1 was maintained at a temperature of 32° C. and filled with ice cream on a standard filling line within 14 seconds after the cone was formed. The cooling effect of the ice cream rapidly crystallizes the cocoa butter equivalent, resulting in a composite frozen confection comprising a rigid cone filled with ice cream. As a receptacle for ice cream, the cone-shaped modified biscuit product acts as a good moisture barrier.

example 3

[0060] Preparation of complex frozen confectionery using cereal cones coated with chocolate mixture

[0061] The process of Example 2 was repeated with an additional step of coating the inner surface of the formed cereal cone with the mixed coating composition prior to filling with ice cream.

[0062] The coating composition is made from a mixture of refined vegetable oil, sugar, cocoa powder and soybean lecithin, and its total oil content is 52-55%. The mixture is passed through a refiner to obtain a particle size of approximately 85% of the particles having an average diameter less than or equal to 25 microns. When using a Brookefield LVT type viscometer with a rotating shaft 21 to measure at 40°C, the plastic viscosity of the mixture is 60-100cP, and the yield value is 3-7D / cm 2 , using 6.5 g of coating material, the mixture was sprayed with a nozzle at a temperature of 50° C. until the inner surface and the upper edge of the cereal cone were completely coated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com