Fluorosilicones and fluorine- and silicon-containing surface treatment agent

A technology of polysiloxane and fluorinated alkyl, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of reducing hydrophobicity and oil repellency, and achieve the effect of good texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0200] The following preparation examples and examples further illustrate the present invention in detail, but should not be construed as limiting its scope. Unless otherwise indicated, all parts and percentages in the examples are based on weight, and all tests are obtained at about 23°C.

[0201] 1. Shower water repellency test (JIS-L-1092)

[0202] According to JIS-L-1092, the spray water repellency test is carried out. The spray water repellency is represented by the hydrophobic number (shown in Table 1 below).

[0203] A glass funnel with a volume of at least 250ml and a nozzle that can spray 250ml of water within 20-30 seconds are used. The sample frame (flame) is a metal frame with a diameter of 15 cm. Three specimens with a size of about 20 cm×20 cm were prepared, and the specimens were mounted on the specimen holding frame so that the specimens had no wrinkles. The center of the spray is located in the center of the proof sheet. Fill the glass funnel with room temperature...

preparation example 1

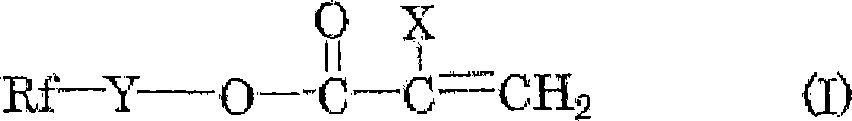

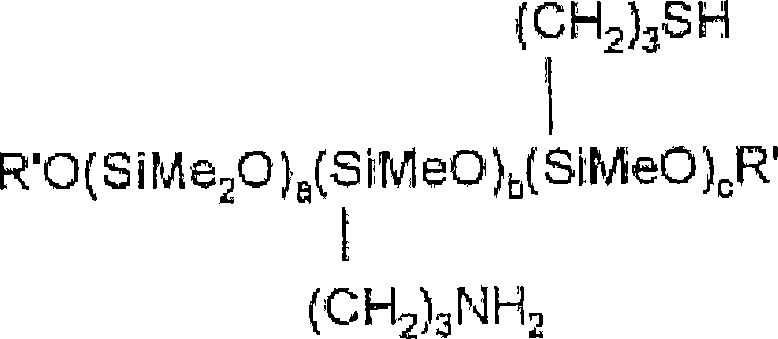

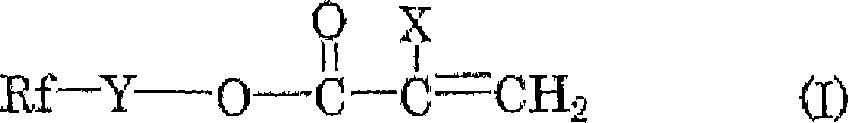

[0234] Fill a 300ml flask with CF 3 CF 2 -(CF 2 CF 2 ) n -CH 2 CH 2 OCOCCl=CH 2 (n=1.0) (33g), stearyl acrylate (18g), N-methylol acrylamide (1.1g), methacrylic acid-3-chloro-2-hydroxypropyl ester (0.53g), silicon Oxyane 2 (2.5g), pure water (66.1g), tripropylene glycol (14.4g), acetic acid (0.11g), polyoxyalkylene (or polyoxyalkylene) ether (0.7g), polyoxyethylene sorbitan Sugar monolaurate (2.8g) and stearyltrimethylammonium chloride (2.1g) were emulsified by ultrasonic at 60°C for 15 minutes with stirring. The atmosphere of the flask was replaced with nitrogen, and then 2,2'-azobis(2-amidinopropane) dihydrochloride (0.3 g) was added and reacted at 60° C. for 3 hours to produce an aqueous polymer dispersion.

preparation example 2

[0236] Fill a 300ml flask with CF 3 CF 2 -(CF 2 CF 2 ) n -CH 2 CH 2 OCOCCl=CH 2 (n=1.0) (33g), stearyl acrylate (18g), N-methylol acrylamide (1.1g), methacrylic acid-3-chloro-2-hydroxypropyl ester (0.53g), silicon Oxyane 2 (1.5g), methyl isobutyl ketone (1.3g), methanol (1.3g), pure water (66.1g), tripropylene glycol (14.4g), acetic acid (0.11g), polyoxyalkylene ether (0.7g), polyoxyethylene sorbitan monolaurate (2.8g) and stearyltrimethylammonium chloride (2.1g) were emulsified by ultrasonic at 60°C for 15 minutes under stirring. The atmosphere of the flask was replaced with nitrogen, and then 2,2'-azobis(2-amidinopropane) dihydrochloride (0.3 g) was added and reacted at 60° C. for 3 hours to produce an aqueous polymer dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com