Device for automatically and continuously recycling doctor solution and recycling technique thereof

A technology of automatic recovery and desulfurization liquid, applied in fertilization devices, nitrogen fertilizers, ammonium nitrate fertilizers, etc., can solve the problems of deterioration of desulfurization operating conditions, black color, low regeneration efficiency, etc., and achieve stable and reliable operation, good economic benefits, The effect of low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

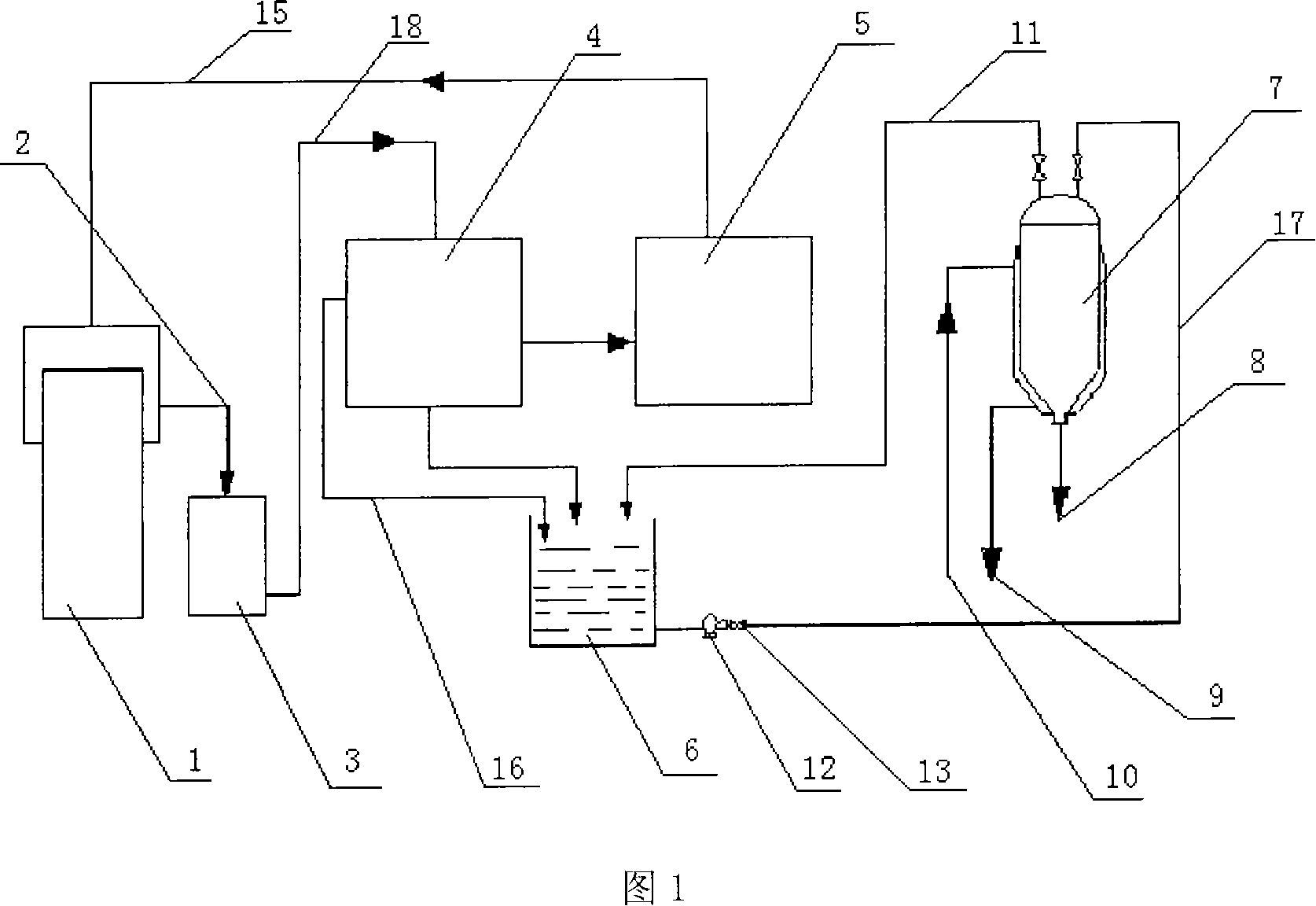

[0017] The structure of the present invention is shown in Figure 1. It is composed of a desulfurization liquid continuous filtration system, a desulfurization liquid automatic recovery system and a continuous sulfur melting system. The systems are connected by pipelines;

[0018] The desulfurization liquid continuous filtration system comprises an oxidation regeneration tank 1, a sulfur foam tank 3 with a discharge port at the bottom and a vacuum filter 4, the oxidation regeneration tank 4 communicates with the sulfur foam tank 3 through a sulfur foam pipe 2, and the sulfur foam The trough 3 communicates with the vacuum filter 4 through a discharge pipe 18, and an overflow pipe 16 is arranged on the vacuum filter 4.

[0019] The desulfurization liquid automatic recovery system includes a desulfurization liquid tank 5, a desulfurization liquid pipe 15 and an oxidation regeneration tank 1 with a negative pressure absorber. The desulfurization liquid tank 5 passes through the desu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com