1,3-propylene glycol redex enzyme isoenzyme variant gene gln202ala and uses thereof

A technology of propylene glycol and reductase, applied in 1 field, can solve problems such as restriction and poor catalytic activity, and achieve the effects of high catalytic activity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The following are embodiments of the present invention:

[0009] 1. Design of error-prone PCR primers and acquisition of PCR amplification products:

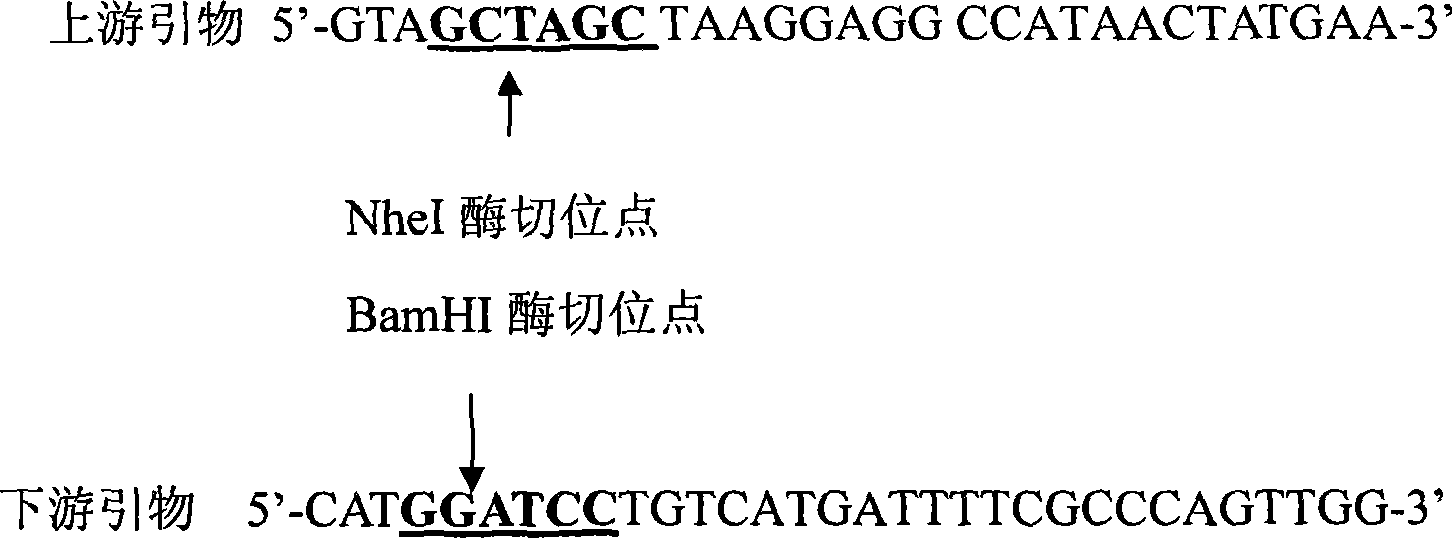

[0010] According to the gene design of 1,3-propanediol reductase isoenzyme, in order to facilitate subsequent operations, BamHI and NheI sites were respectively introduced into the 5' end of the primers.

[0011]

[0012] To a 500 μl eppendorf tube, add 100 pmol of dNTPs, 20 pmol of each upstream primer, 20 pmol of downstream primer, approximately 1 ng of pET28α(+)yqhD as template DNA, and a final concentration of 0.05 mM MnCl 2 , 2.5uTaqDNA polymerase, 5μl PCR buffer, 12.5μl 25mM MgCl 2 , and then add sterile distilled water to a total volume of 50 μl. The reaction parameters were denaturation at 95°C for 5 minutes, followed by 35 cycles of 1 min at 95°C, 2 min at 54°C, and 1 min at 72°C, and then extended at 72°C for 2 min to obtain PCR amplification products.

[0013] 2. Construction of mutant library:

[0014] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com