Multiple quantum well nitride light emitting diode with carrier supplying layer

A nitride and carrier technology, which can be used in phonon exciters, lasers, laser parts, etc., and can solve problems such as cost and doping of light-emitting layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

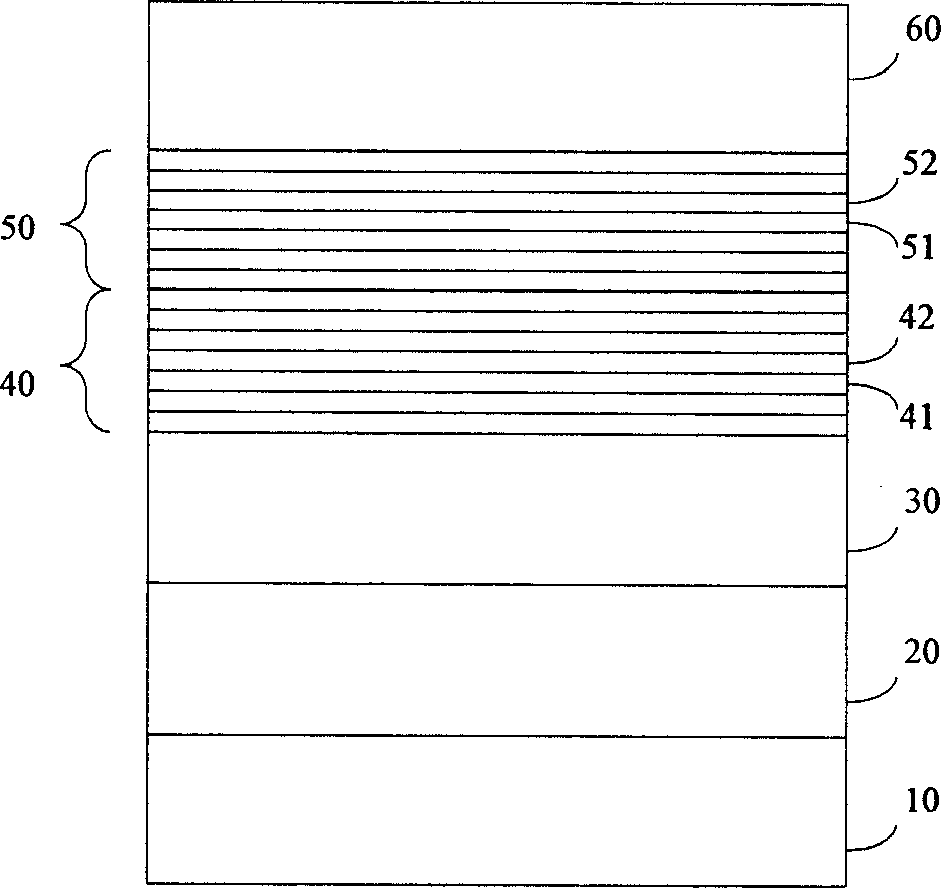

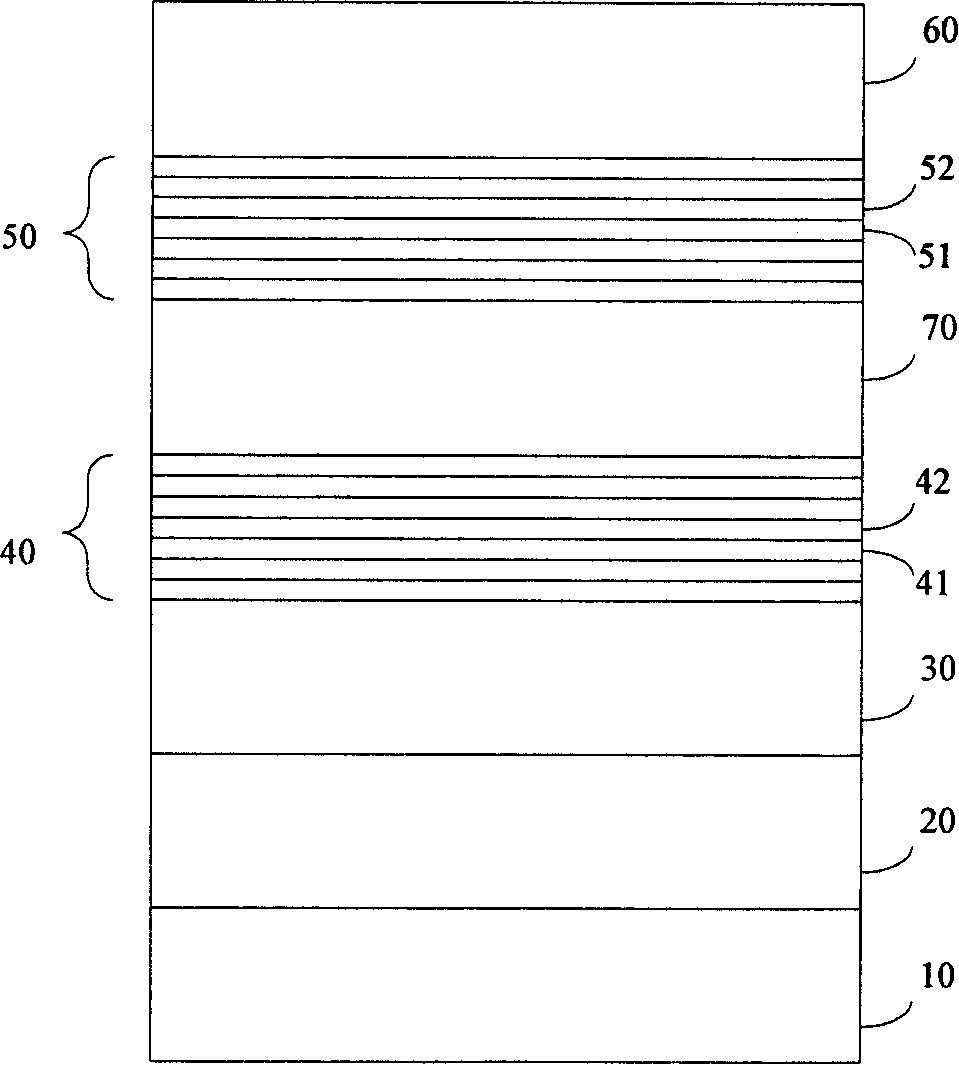

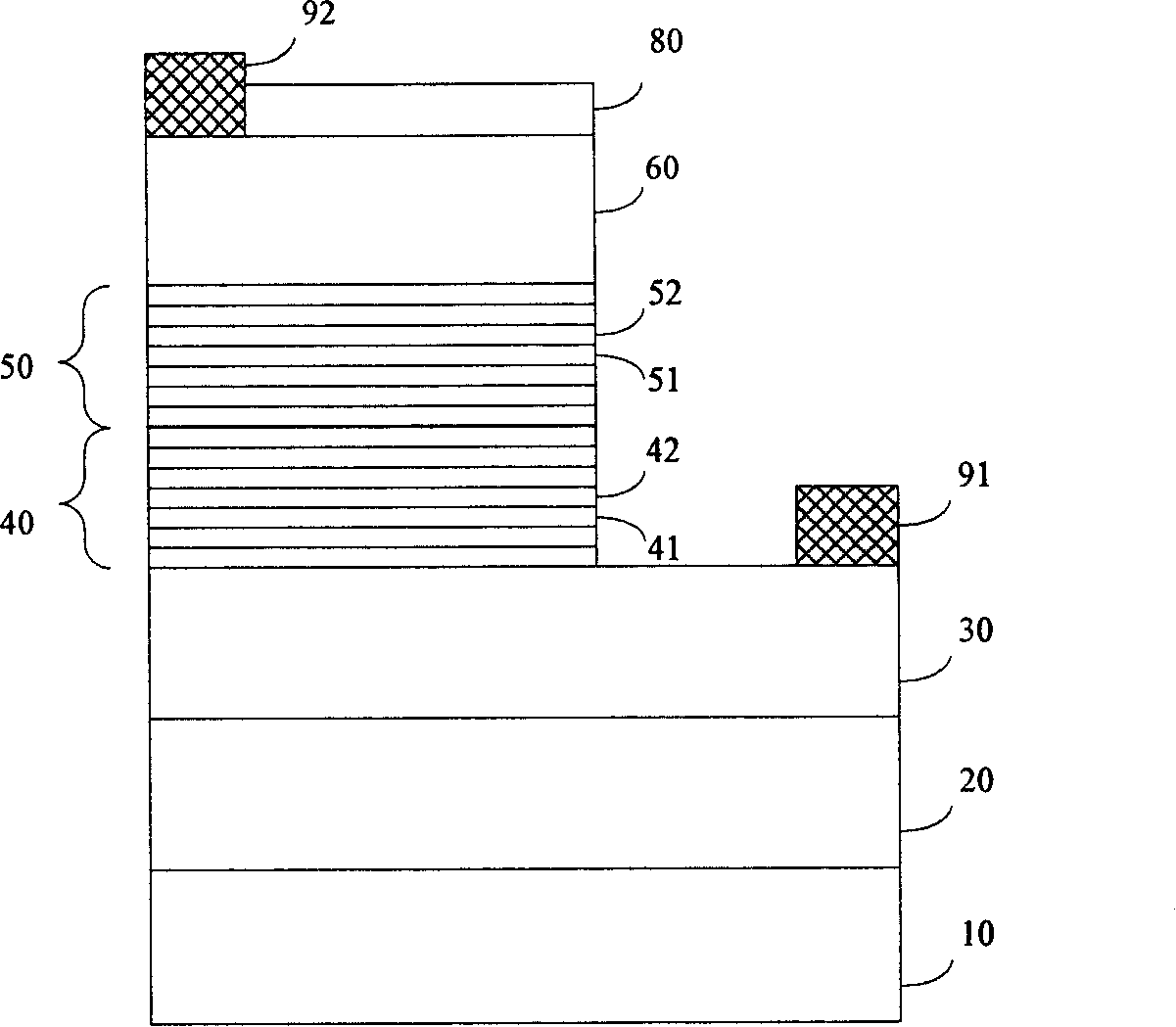

[0023] figure 1 Shown is a schematic diagram of a nitride MQW LED structure according to a first embodiment of the present invention. Please note that this specification uses the term "LED structure" to refer to the epitaxial structure of an LED, and the term "LED device" to refer to the formation of an LED structure, and then through the subsequent chip process (chip process) in the LED A semiconductor device obtained after electrodes are formed on the structure.

[0024] Such as figure 1 As shown, at the bottom of the above-mentioned LED structure, the substrate 10 is usually made of aluminum oxide single crystal (sapphire) or an oxide single crystal with a lattice constant close to that of the epitaxial layer of the LED structure. The substrate 10 can also be made of SiC (6H-SiC or 4H-SiC), Si, ZnO, GaAs, or MgAl 2 o 4 to make. Generally, the most common material for the substrate 10 is sapphire or SiC. On the upper surface of the substrate 10, then formed by Al a Ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Electron concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com