High-purity vinylene carbonate and a method of purifying vinylene carbonate

A vinylene carbonate, high-purity technology, applied in organic chemistry and other fields, can solve the problems of ambiguous purity data and no detailed disclosure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0064] The purification of example 1 VC:

[0065] Only crude VC substantially free of polymeric impurities by initial distillation without a (distillation) column was used as starting material.

[0066] The purity of this crude VC is about 97% and the content of organic and inorganic chlorine is about 0.5% to 1%.

[0067] Gas chromatography analysis was performed by HP6890. Separation was performed by a 50 meter long CP-Sil 8 CB with 0.53 mm ID and 1.0 μm FD.

[0068] The carrier gas was nitrogen with an inlet pressure of 5 psi. The syringe was operated at a flow rate of 138 ml / min with a 30 / 1 split. Inject 1 μl of pure VC.

[0069] The injector temperature was 220°C and the monitor temperature was 320°C. The temperature program starts at 50°C and heats up to 250°C at 5°C / min.

[0070] Evaluations were performed according to the standard percentage method.

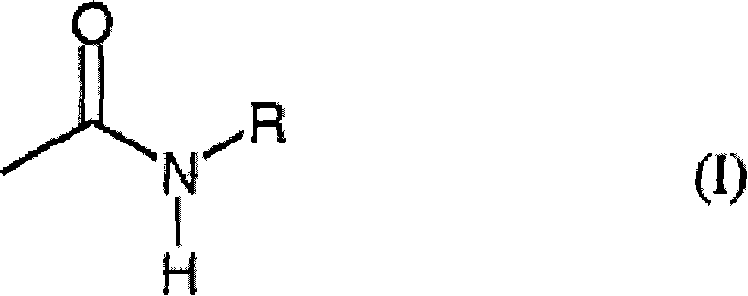

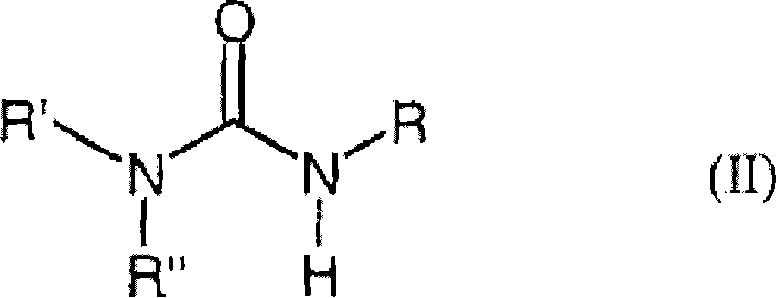

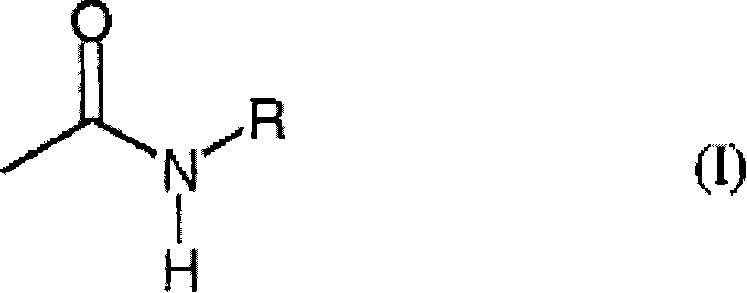

[0071] First processing stage: Treat with urea at 140°C, filter out with air suction, dilute with NMP:

[0072] ...

example 2

[0091] The characteristic comparison of example 2 liquid VC and solid VC

[0092] Samples of vinylene carbonate purified according to Example 1 were stored in liquid state at 20° C. and in crystalline form at 5° C. without stabilizers and protected from light.

[0093] Liquid VC

[0094] The stabilizer-free vinylene carbonate sample exhibited mild to severe yellow discoloration and slight clouding after 70 days. The content was mostly 96% as measured by ISTD. Liquid, high-purity vinylene carbonate is storage-unstable in the absence of a stabilizer.

[0095] Solid VC

[0096] The solid samples stored at 5°C were all colorless and clear even after 365 days, after melting. Analysis showed no change in mass. Vinylene carbonate without stabilizer is stable in solid state storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com