Stacked type solid electrolytic capacitor and method for manufacturing same

A solid electrolysis and capacitor technology, applied in the direction of solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of increased load on the anode terminal 52, deviation of connection strength, poor electrolytic capacitors, etc., and achieve good energization status, increased strength, Mitigate adverse effects of LC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

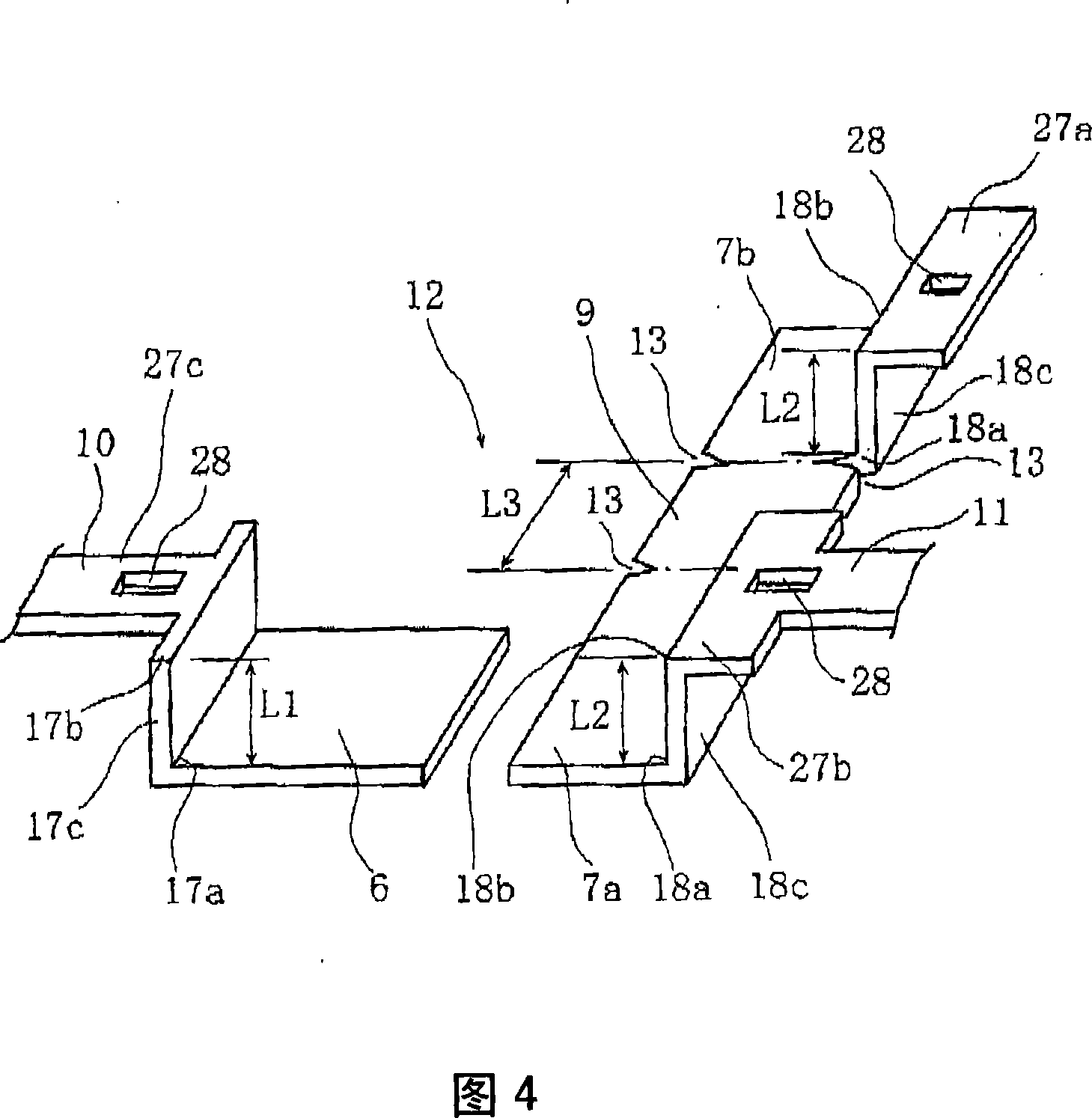

[0079] In the lead frame 12 shown in FIG. 7 , the configuration is the same as that of the above-mentioned best mode except that the number of cathode mounting portions 6 corresponding to the number of anode mounting portions 7 b is provided. In addition, the same code|symbol is attached|subjected to the member which has the same function as the above-mentioned best mode. Specifically, the cathode attachment portion 6 has the same juxtaposition structure as the anode attachment portions 7a, 7b, and is arranged in parallel at predetermined intervals and in the same shape. With regard to such lead frame 12, as shown in FIG. Part 6 is electrically connected.

[0080] By employing such a structure, the anode and the cathode of the capacitor element 30 can be stably blocked when the capacitor element 30 is laminated and when the lead frame 12 is bent.

[0081] In addition, as shown in FIG. 9, the cathode mounting parts 6, 6 are also connected by the connection part 21 similarly t...

Deformed example 2

[0083] As shown in FIG. 10, except that a notch 13a is provided between the anode mounting portions 7a, 7b of the lead frame 12, the configuration is the same as the above-mentioned best mode.

[0084] In such a lead frame 12, the laminated solid electrolytic capacitor can be fabricated by bending it upside down, in contrast to the above-mentioned best mode, so that the anode mounting part 7a and the anode mounting part 7b can pass through an extremely short (with the two The total thickness of the two anode mounting parts 7a, 7b is equal to the length) of the connecting part 9.

[0085] In addition, in the above configuration, although a gap is generated between one capacitor element 30 group and the cathode mounting portion 6, as shown in FIGS. 11 and 12, by interposing the conductive adhesive 14 between the gaps, the The cathode mounting part 6 is electrically connected to the cathode part 30b adjacent to the cathode mounting part 6 .

Deformed example 3

[0087] As shown in Figure 13, except that one more cathode mounting part 6 and anode mounting part 7b are provided in the lead frame (that is, the cathode mounting part and the anode mounting part are provided three by three), the structure is the same as that of the above-mentioned modification 1. .

[0088] Specifically, as shown in FIG. 14 , one anode mounting portion 7 b is folded in the same direction as the first modification, and the other anode mounting portion 7 b is folded in the opposite direction to the first modification. According to such a configuration, more capacitor elements 30 can be mounted.

[0089] In addition, the continuous number of the three anode mounting parts 7a, 7b can be increased within the range allowed by the design as required, and can be 4 or 5. In this case, the bending direction is reversed sequentially.

[0090] (something else)

[0091] (1) In the above method, the notch 13 that is easy to bend the lead frame 12 is formed at the bound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com