Generating discrete gas jets in plasma arc torch applications

A plasma and jet flow technology, applied in the direction of plasma, plasma welding equipment, electrical components, etc., can solve the problems of instability of plasma gas flow, destruction of plasma gas flow, poor processing of workpieces, etc., to achieve cooling improvement, Reduced surface roughness and waviness, effective workpiece machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

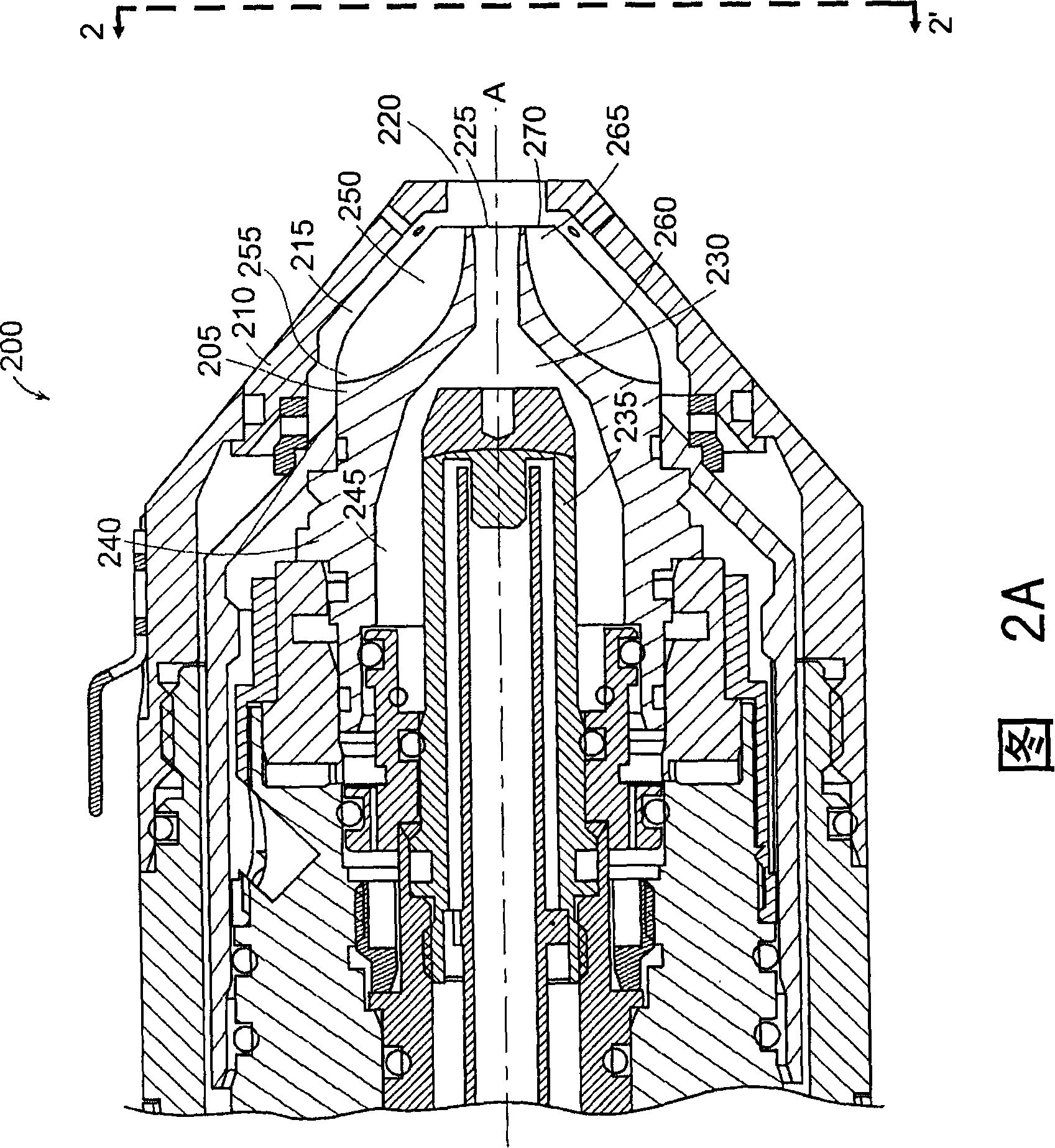

[0036] Figure 2A depicts an exemplary embodiment of a fluid passage provided within a nozzle of the present invention. FIG. 2 shows a torch tip 200 comprising a nozzle 205 having a shield 210 mounted coaxially therewith along the longitudinal axis A and spaced apart. Both nozzle 205 and shield 210 may be made of electrically conductive material. In some embodiments, nozzle 205 and shield 210 are made of the same conductive material. In other embodiments, nozzle 205 and shield 210 are made of different conductive materials. Examples of conductive materials suitable for use in torch tip 200 include, but are not limited to, pure copper, aluminum, or brass. In the illustrated embodiment, the nozzle 205 and shield 210 are mounted in spaced relation to each other forming an auxiliary fluid passage 215 therebetween.

[0037] During workpiece processing, a fluid such as an auxiliary gas may flow along auxiliary fluid passage 215 and ultimately from torch tip 200 through outlet port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com