Alkalization, decolorizing and deodorization integration pan for camellia oil precision machining

A decolorization and deodorization technology, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems such as difficulty in meeting organic edible oil standards, large investment in production sites and equipment, and loss of fragrance of camellia oil products. Equipment investment, long processing cycle, and the effect of preventing the rise of acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

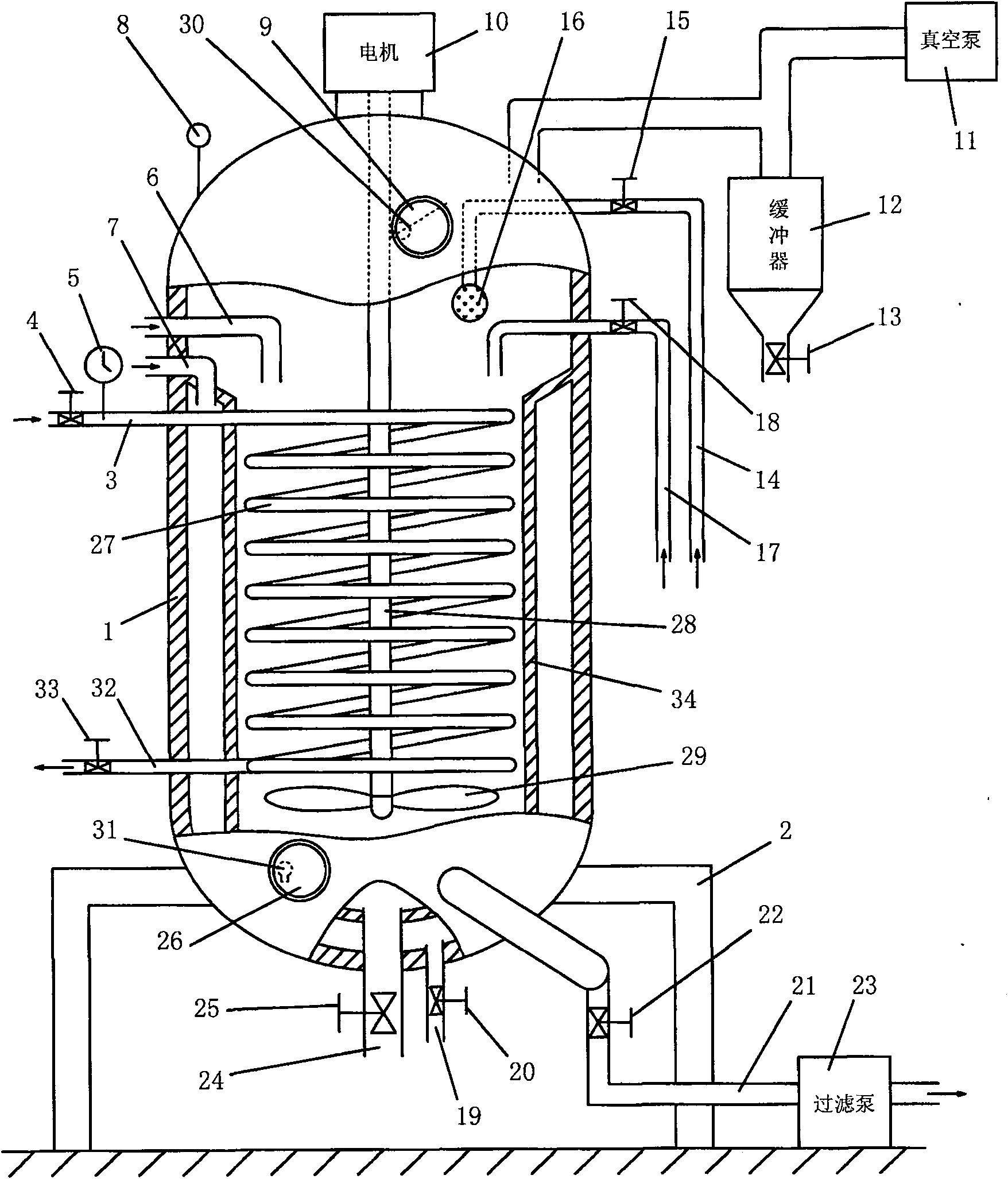

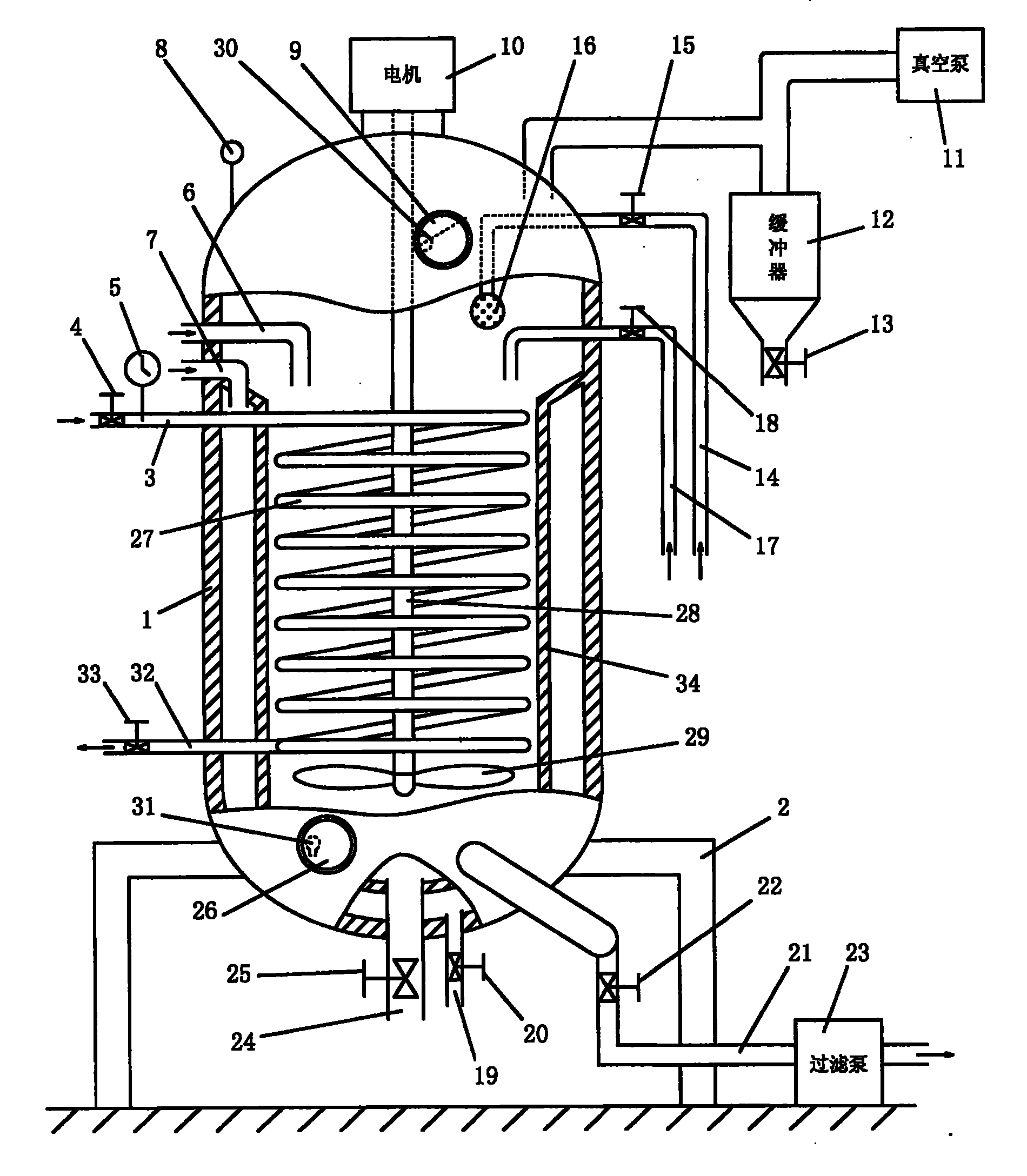

[0019] Embodiment 1: (parts and structure of comprehensive pot)

[0020]A comprehensive boiler for alkalization, decolorization and deodorization of refined camellia oil. The comprehensive boiler includes a pot body 1 and a pot support 2. A steam inlet pipe 3 and a steam pipe valve are arranged on the outer walls of the pot body 1 around the pot body. 4. Steam pressure gauge 5, oil inlet pipe 6, water inlet pipe 7, thermometer 8, viewing hole A9, motor 10, vacuum pump 11, buffer 12, buffer valve 13, suction pipe 14 for sucking water or lye, suction Liquid pipe valve 15, liquid spray ball 16, activated carbon pipe 17, activated carbon pipe valve 18, water outlet pipe 19, water outlet pipe valve 20, oil outlet pipe 21, oil outlet pipe valve 22, filter pump 23, waste water outlet pipe 24, Out of waste water pipe valve 25, sight hole B26, out of steam pipe 32 and out of steam pipe valve 33; in pot body 1, spiral steam heating pipe 27, rotating shaft 28, stirring blade 29, scraper ...

Embodiment 2

[0021] Embodiment 2: (the use of comprehensive pot)

[0022] A method of using a comprehensive pot for alkalization, decolorization and deodorization of refined camellia oil is carried out according to the following steps:

[0023] (1) Camellia oleifera seeds are pressed to extract crude oil;

[0024] (2) Alkali refining and deacidification: the crude oil is input into the pot body 1 through the comprehensive pot oil inlet pipe 6 of the present invention until it is aligned with the oil inlet pipe 6, and the water inlet pipe 7 is opened (the water outlet pipe 19 is closed) to allow water to flow into the interlayer inner wall 34 of the pot body In the sealed chamber formed between the outer wall of the pot body 1 (for heat preservation), the steam inlet pipe 3 and the steam outlet pipe 32 are opened, and the steam is heated to 20-30°C through the steam heating pipe 27; the vacuum pump 11 is started to adjust After the vacuum, the lye is inhaled according to the amount through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com