Method for preparing silver nano antibacterial material

An antibacterial material, silver nanotechnology, applied in the field of preparing silver nanometer antibacterial materials, can solve problems such as complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

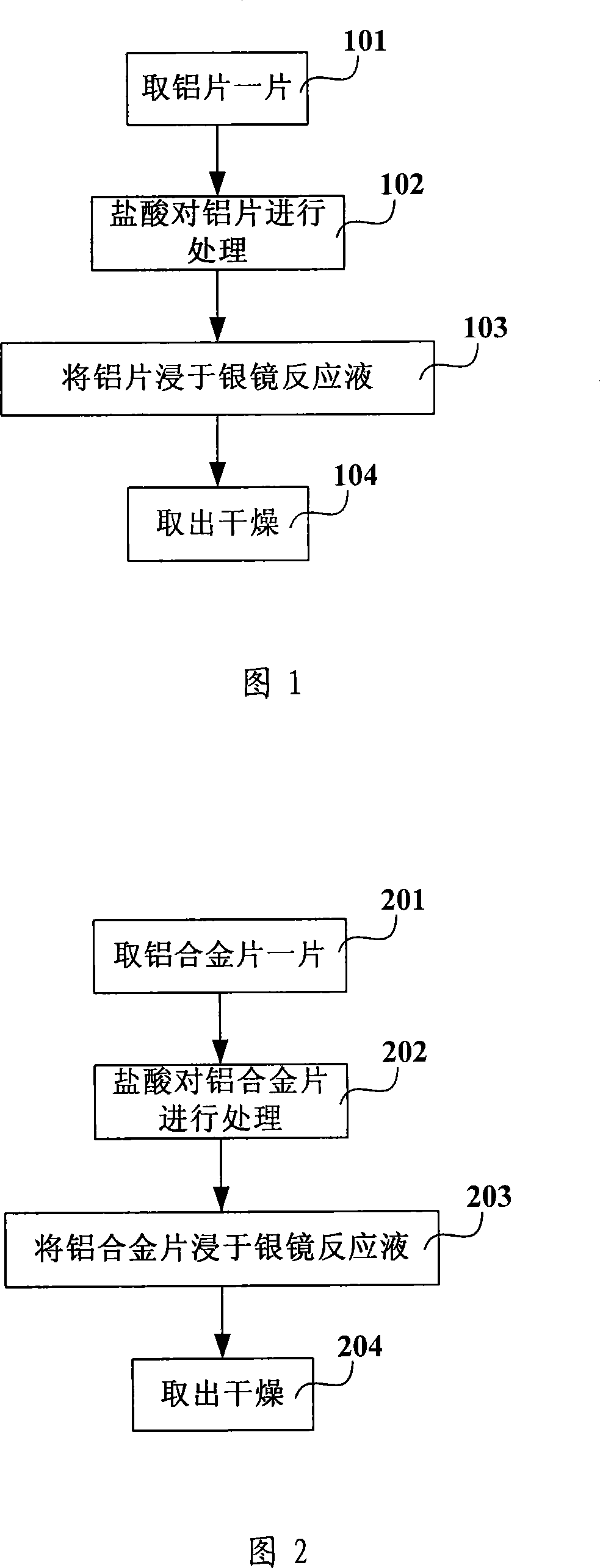

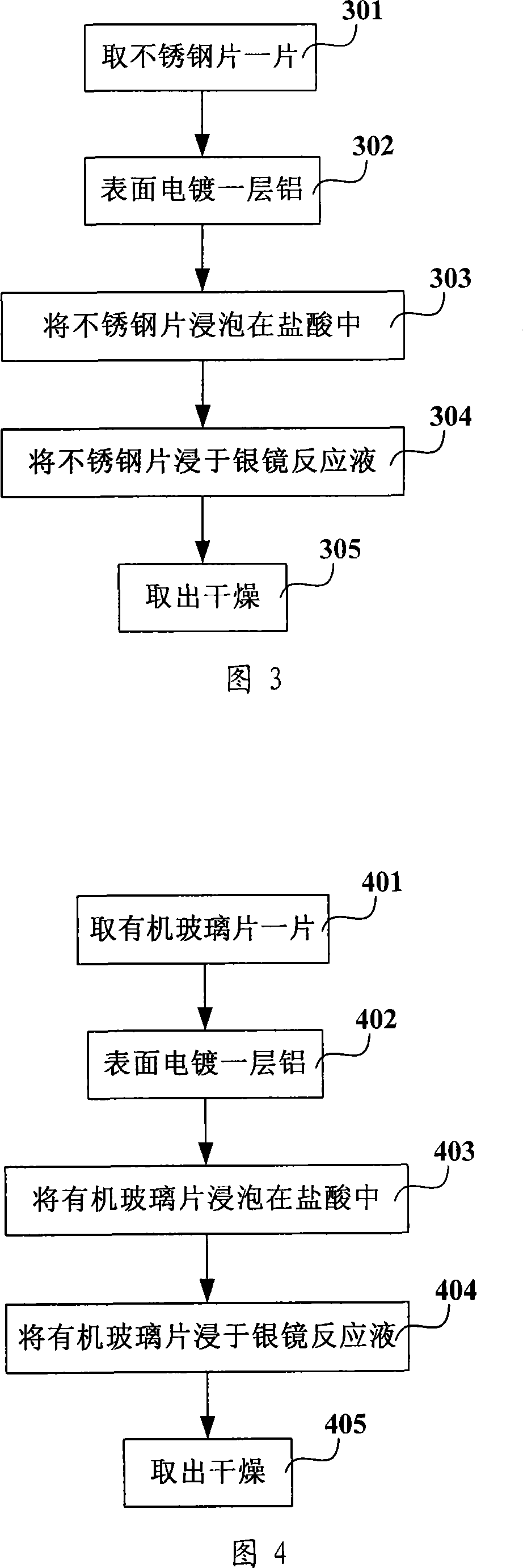

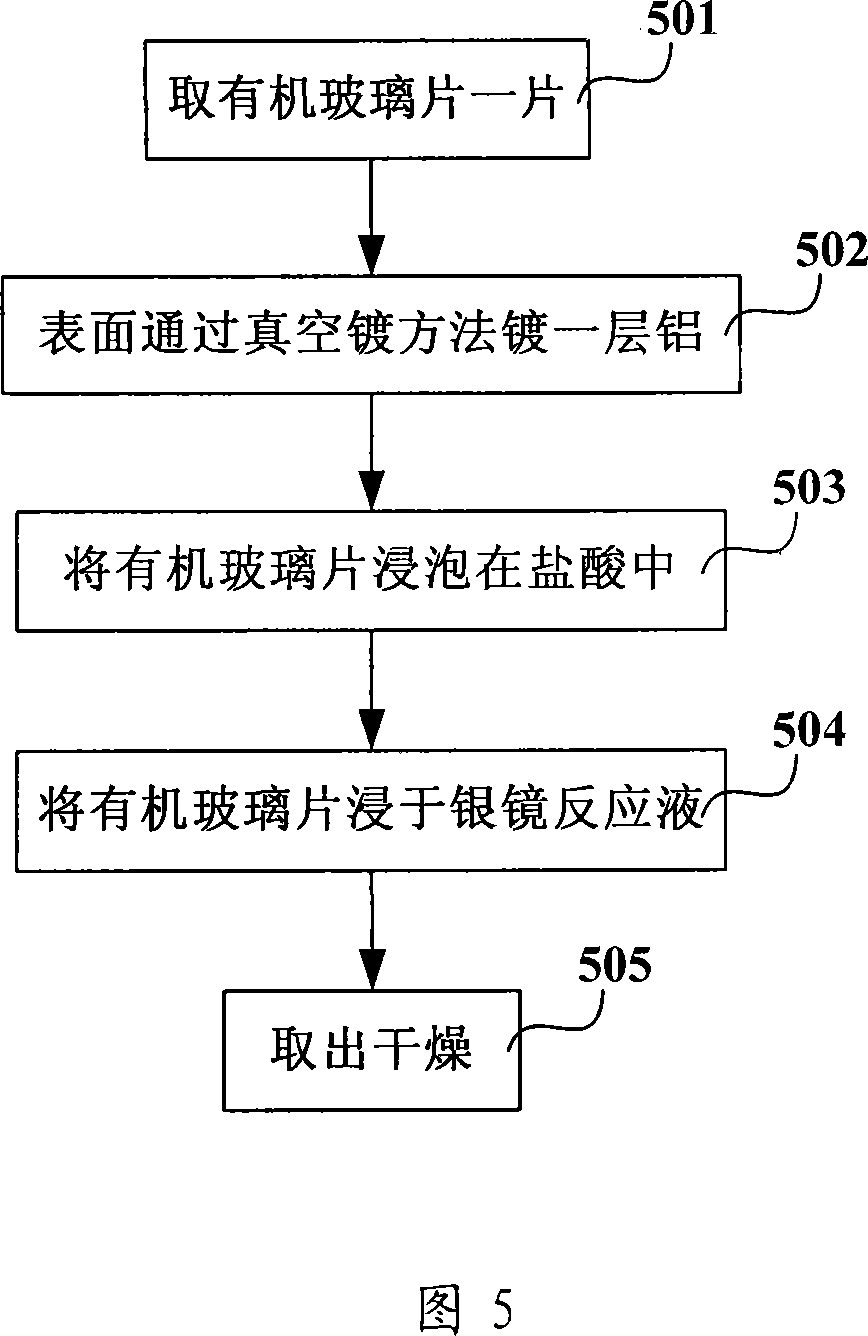

[0018] The substrate can be metal products such as aluminum, copper, iron, aluminum alloy, stainless steel, etc., or non-metallic products such as plexiglass. By preparing an aluminum ion film on the surface of the substrate, the different crystal planes of silver are changed when participating in the silver mirror reaction. growth rate, thereby inducing the growth of the flaky silver nanosheet structure, and the resulting nanosheet structure is maintained due to the growth advantage of longer nanosheets. When the substrate contains aluminum metal, the surface of the substrate can be treated with an acidic solution to form an aluminum ion film; when the substrate does not contain aluminum metal, a layer of aluminum can be placed on the surface of the substrate first, and then treated with an acidic solution. An aluminum ion film is formed on the surface of the substrate. Wherein, the acid solution can be hydrochloric acid, nitric acid, etc., and the concentration is preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com