Explosion welding manufacturing method of aluminum-titanium composite material

A composite material and explosive welding technology, which is applied in the manufacture of tools, welding equipment, explosives, etc., can solve problems such as low bonding strength, difficulty in leveling, and tearing of titanium plates, and achieve high bonding strength, convenient production, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

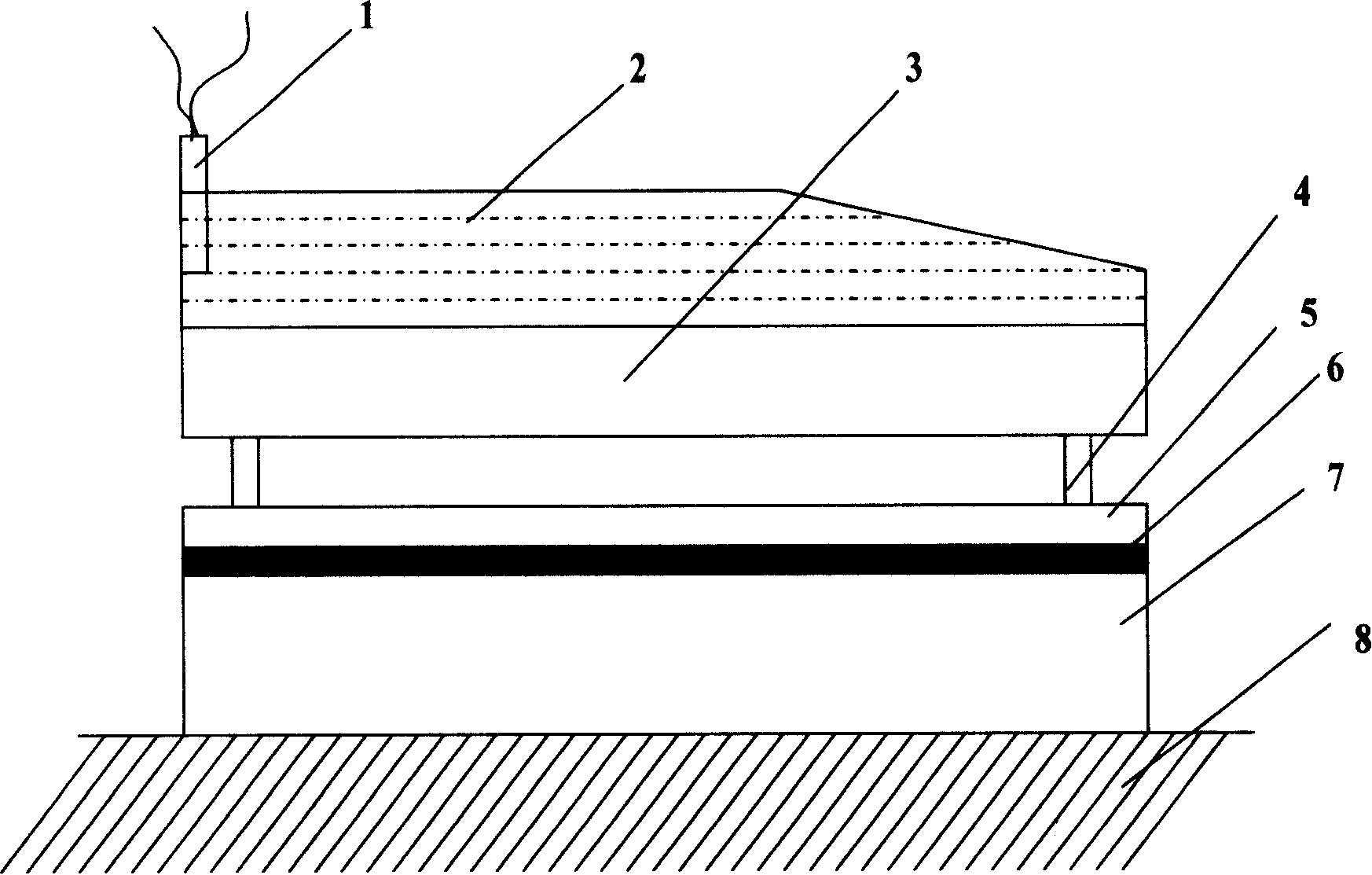

specific Embodiment approach 3

[0017] Manufacture a piece of aluminum alloy-titanium composite material, which can also be applied to aluminum alloy plates. The grade of the base titanium plate is TA2, the size is 6×1500×2800mm, the double layer is aluminum alloy 5083, the size is 8×1500×2800mm, the double layer The support height between the aluminum alloy plate and the base titanium plate is 7mm, and the surface of the steel backing plate is paved with a buffer protection layer. Ammonium ladder explosives are used and placed directly on the surface of the aluminum layer. The charge per unit area at the detonating end is 3.00g / cm 2 , the amount of charge per unit area within the range of 700mm at the end of the detonation direction is gradually reduced to 1.6g / cm 2 , detonated with an industrial electric detonator, and the aluminum alloy-titanium composite material obtained by explosive welding has good composite quality and good shape. Tensile strength ≥ 100Mpa, explosive composite rate 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com