Technique for rewashing symbiosis mine tailing of copper and molybdenum

A technology for tailings and processes, which is applied in the field of copper-molybdenum symbiosis tailings reprocessing technology, can solve the problems of high tailings rate and backward beneficiation technology, and achieve the effect of improving the recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Sample preparation: multi-point sampling to ensure the representativeness of the ore samples used in the test. Then mix and divide, and prepare 5000 parts with 500g / bag to ensure the standardization and uniformity of the condition test ore samples.

[0024] 2. Regrinding test: Firstly, whether regrinding is necessary, the tailings samples were screened and analyzed, and the results are shown in Table 2:

[0025] Table II:

[0026]

Particle size (m / m)

+1

-1+0.5

-0.5+

0.3

-0.3+

0.15

-0.15+

0.074

-0.074

copper metal distribution

Rate(%)

18.66

26.75

16.82

10.17

15.28

12.32

Molybdenum metal distribution

Rate(%)

20.05

23.23

18.76

13.18

16.83

7.92

[0027] It can be seen from the above table that ...

Embodiment 2

[0032] In the drug dosage test, we used an orthogonal test to determine the optimal dosage of various drugs. See Table 4 for the types and dosage of drugs.

[0033] Table four

[0034]

[0035] Because the tailings re-election is a secondary separation and needs to be re-grinded, a large amount of secondary ore sludge will be produced, and its existence will make the flotation index worse, such as: the recovery rate is reduced, the quality of the concentrate is deteriorated, and the reagent Consumption increases, flotation speed slows down, and dehydration processes such as sedimentation and filtration are affected. In order to prevent the above harmful consequences, after a large number of proportioning tests, sodium sulfide is adsorbed on the surface of slime particles, which increases the surface hydrophilicity and the resistance of mutual agglomeration , so as to prevent useful minerals and gangue fine mud from adhering to each other, which is conducive to improving the...

Embodiment 3

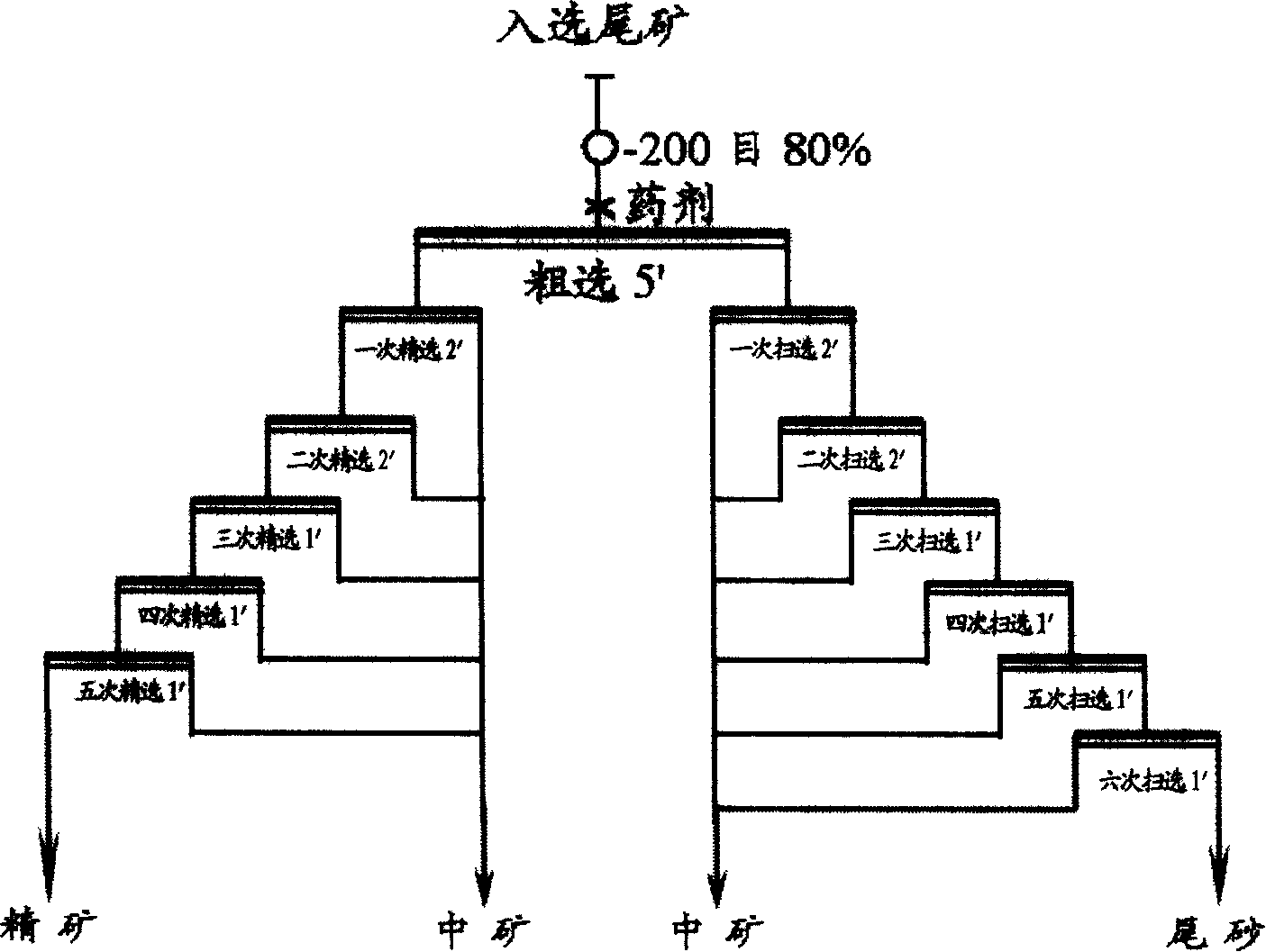

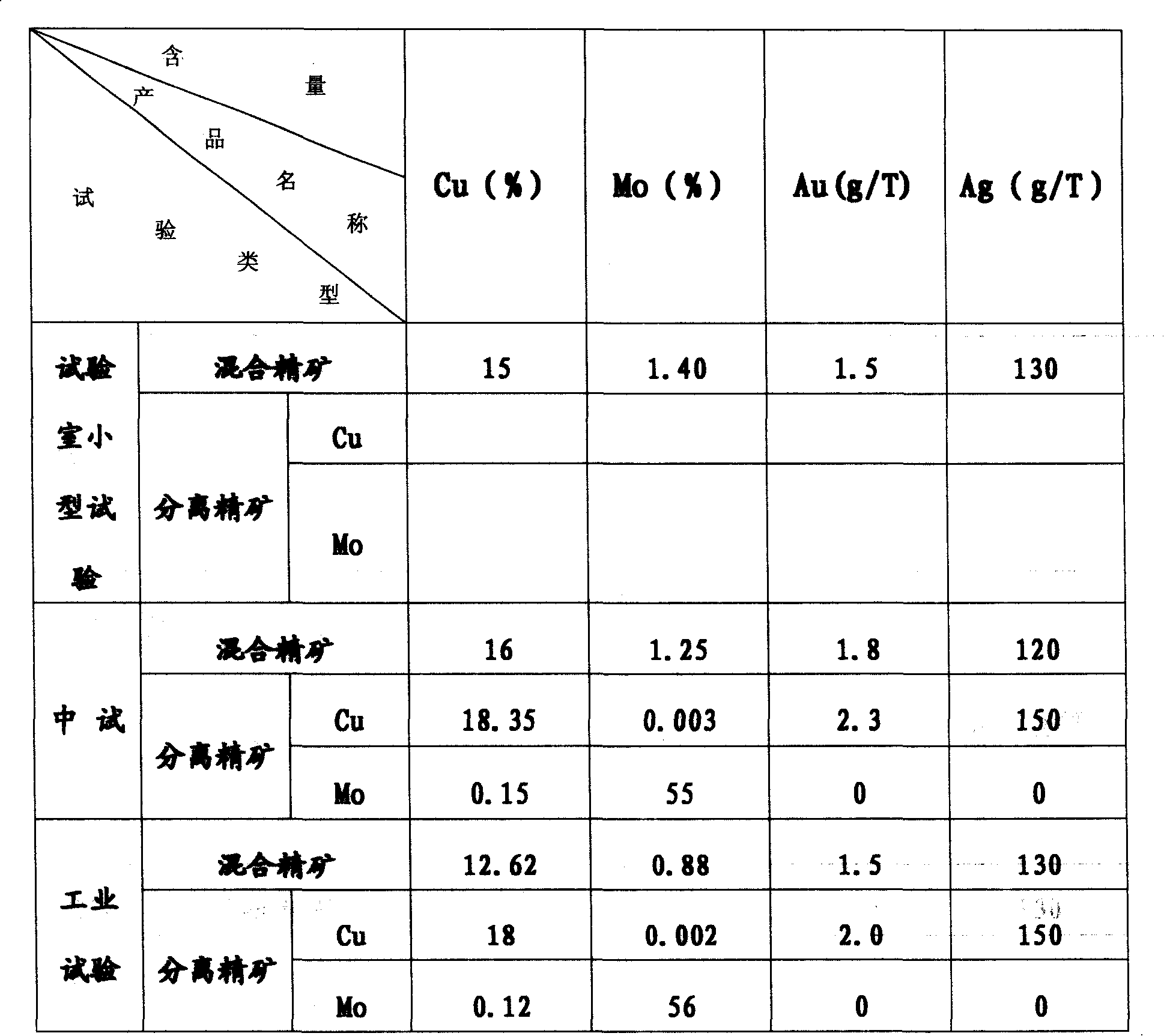

[0038] see process figure 1 , the results are shown in Table 5.

[0039] Table five

[0040]

[0041] From Table 5, the final determination process of this test process is the process flow of classification regrinding, first roughing, second sweeping, second refining, and medium ore return process.

[0042] The innovation and improvement of the technological process is summarized as follows: firstly, the test was carried out according to the ordinary beneficiation process mode. The process is first grinding and then grading, and finally enters the flotation. It adopts the process of grading first, then grinding, and then enters the flotation process, which avoids the phenomenon of slurry muddying and achieves a better flotation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com