Premix rotational flow flat-flame type combustor for hot-air engine

A burner and heat engine technology, applied to gas fuel burners, burners, burning with multiple fuels, etc., can solve the problems of long flame length, insufficient combustion, poor mixing of burner air and combustible gas, etc., to achieve Meet the requirements of compact size, compact structure and easy layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

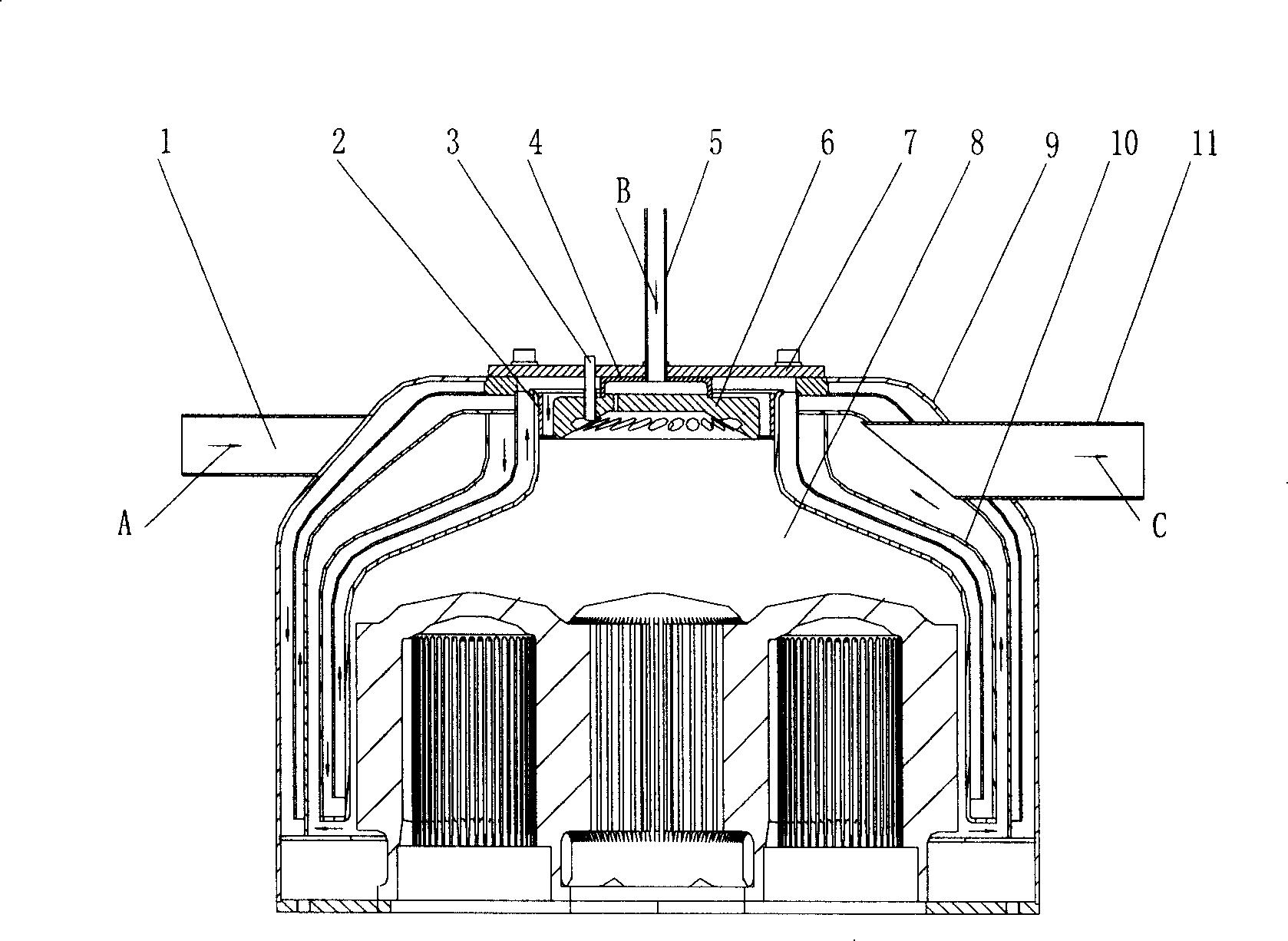

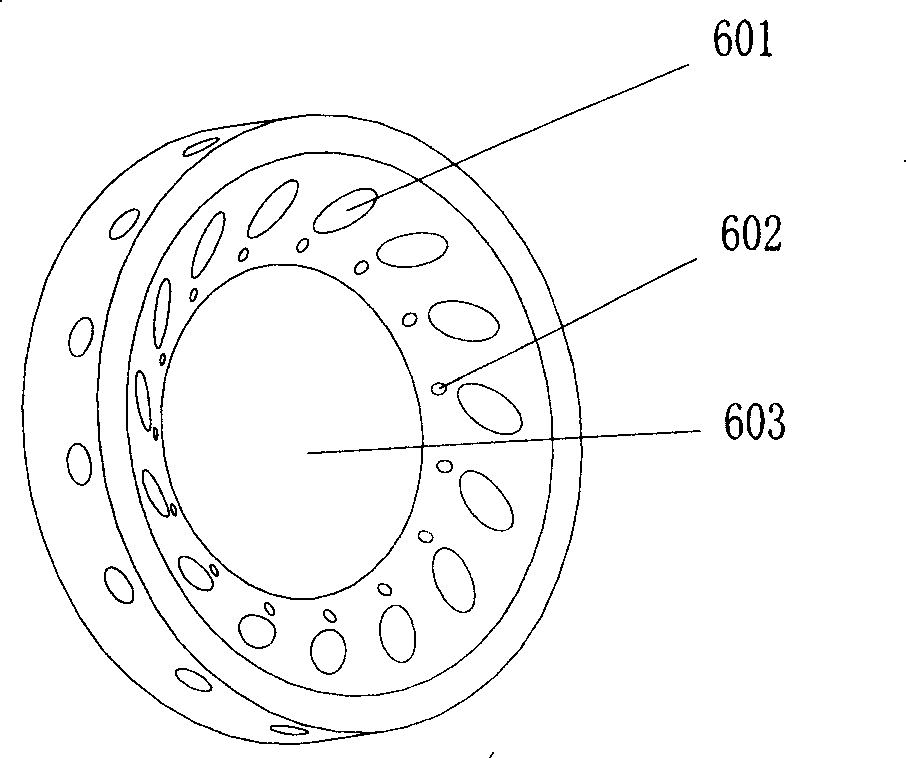

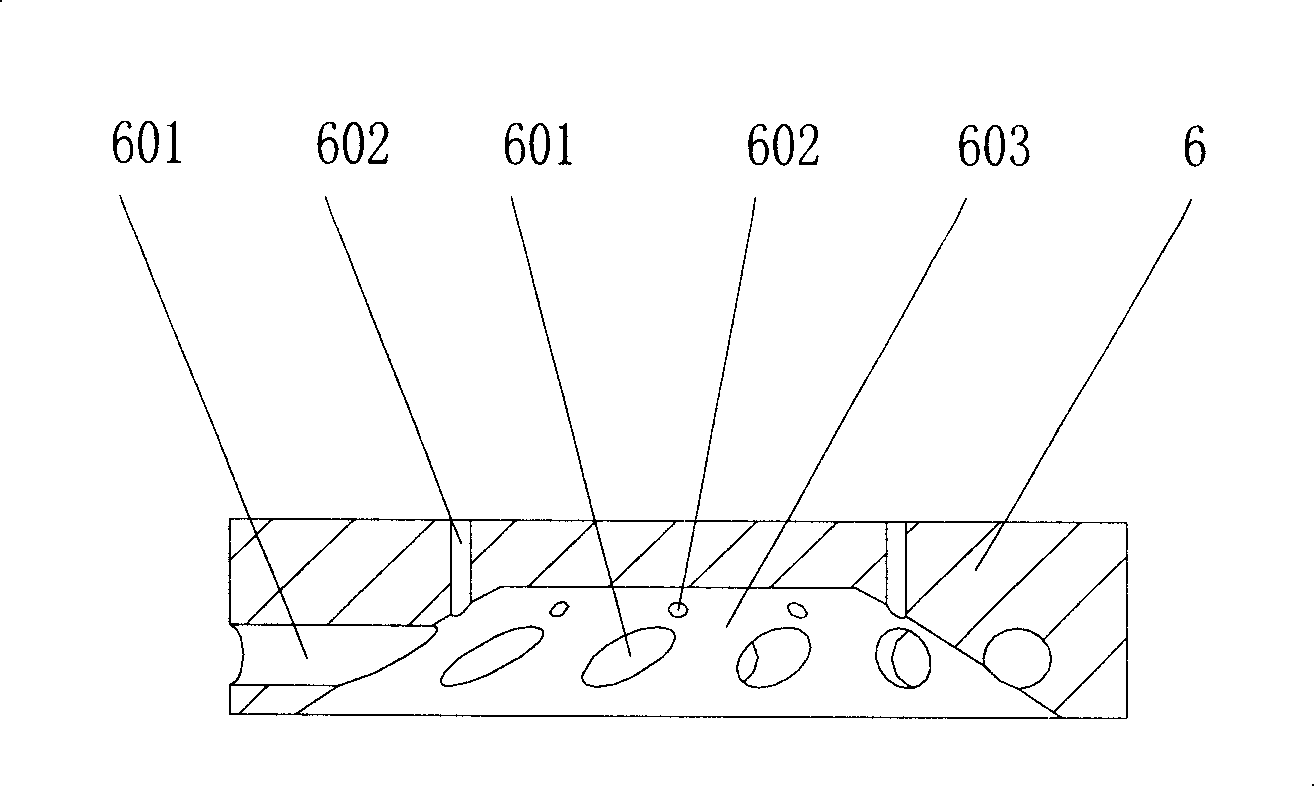

[0024] figure 1 Shown is the structural layout diagram of the present invention, the burner belongs to the normal pressure burner, is arranged on the top of the heater of the hot gas engine, and forms the combustion chamber 8 space in the upper space of the heater. The burner is mainly composed of a combustible gas inlet pipe 5, an air inlet pipe 1, an exhaust gas exhaust pipe 11, an air preheater 10, a burner body 6, a combustible gas distributor 4, a preheating air distributor 2, an igniter and a combustion chamber. Chamber 8 housing and other components. The air preheater 10 is a multi-layer thin-walled shell structure, which is usually welded by sheet metal parts. Its shape is approximately bell-shaped, with an open top, and the internal space gradually increases from top to bottom. body, the lower half is surrounded by the heater of the heat engine, together with the heater to form the combustion chamber 8 space; the outer periphery of the air preheater 10 is the burner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com