Gas burner

A gas burner, air technology, applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of insufficient gas combustion, damage to the life of the stove, harmful to human health, etc., to achieve sufficient gas combustion and flame temperature Improvement, the effect of sufficient oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

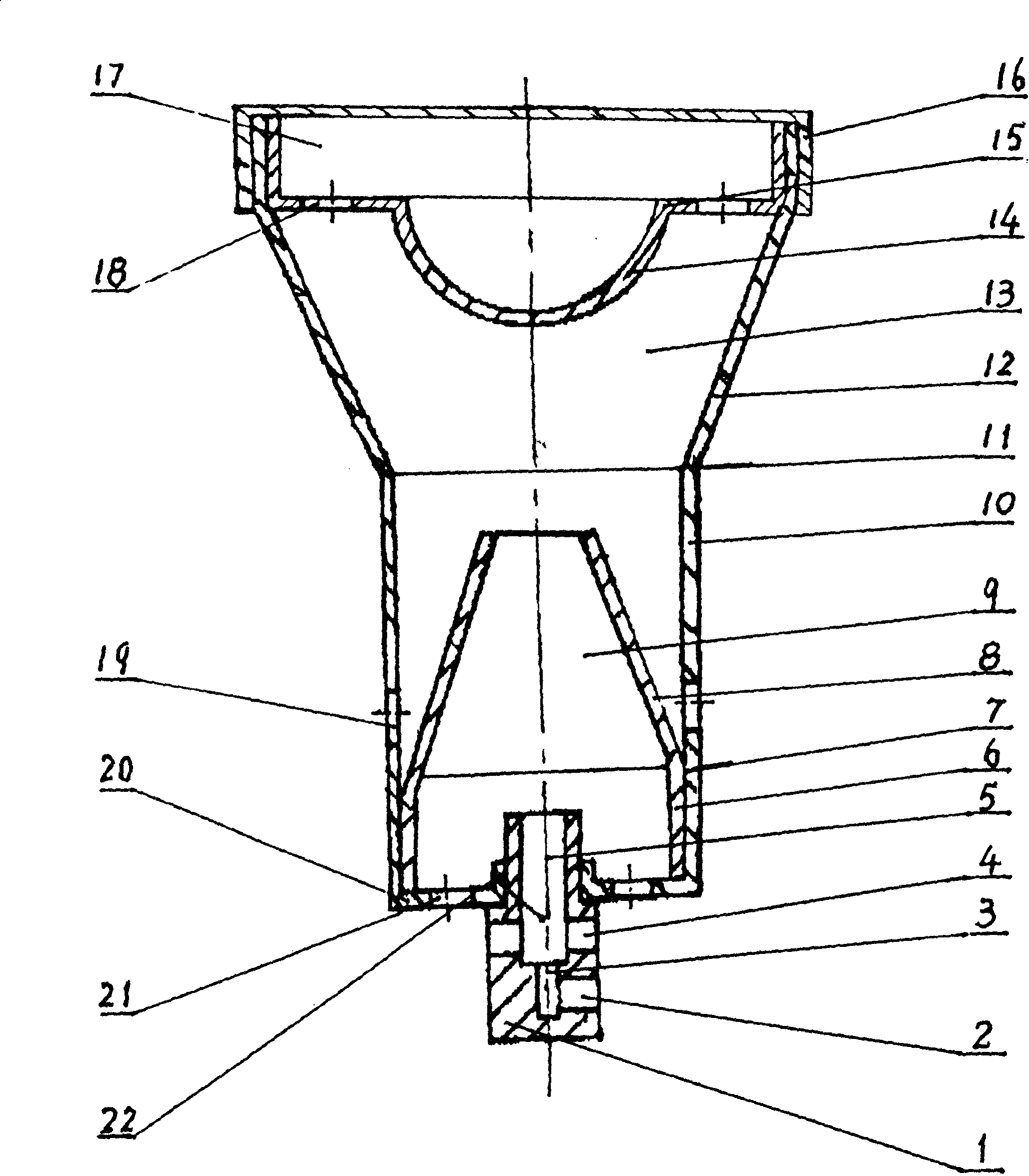

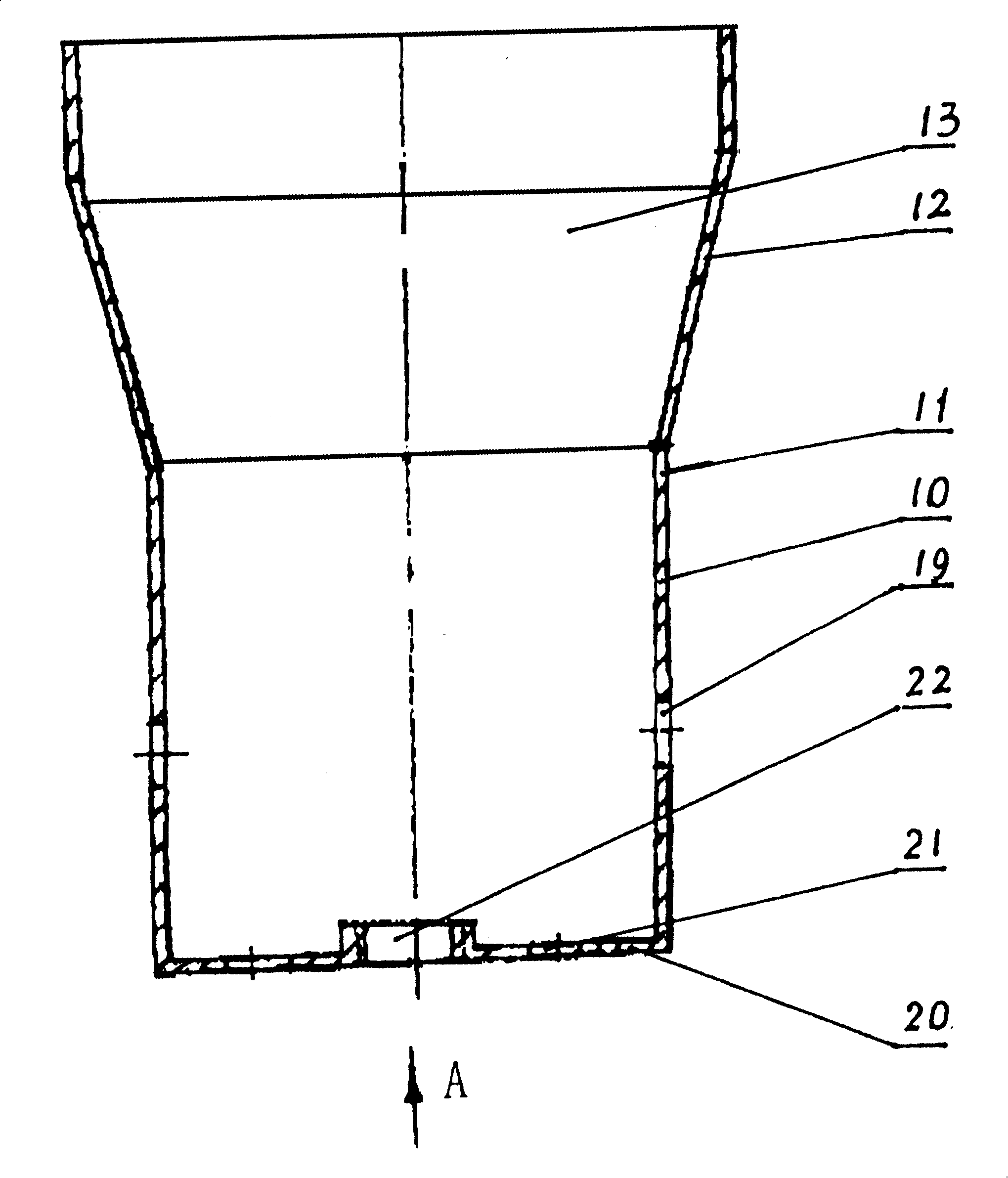

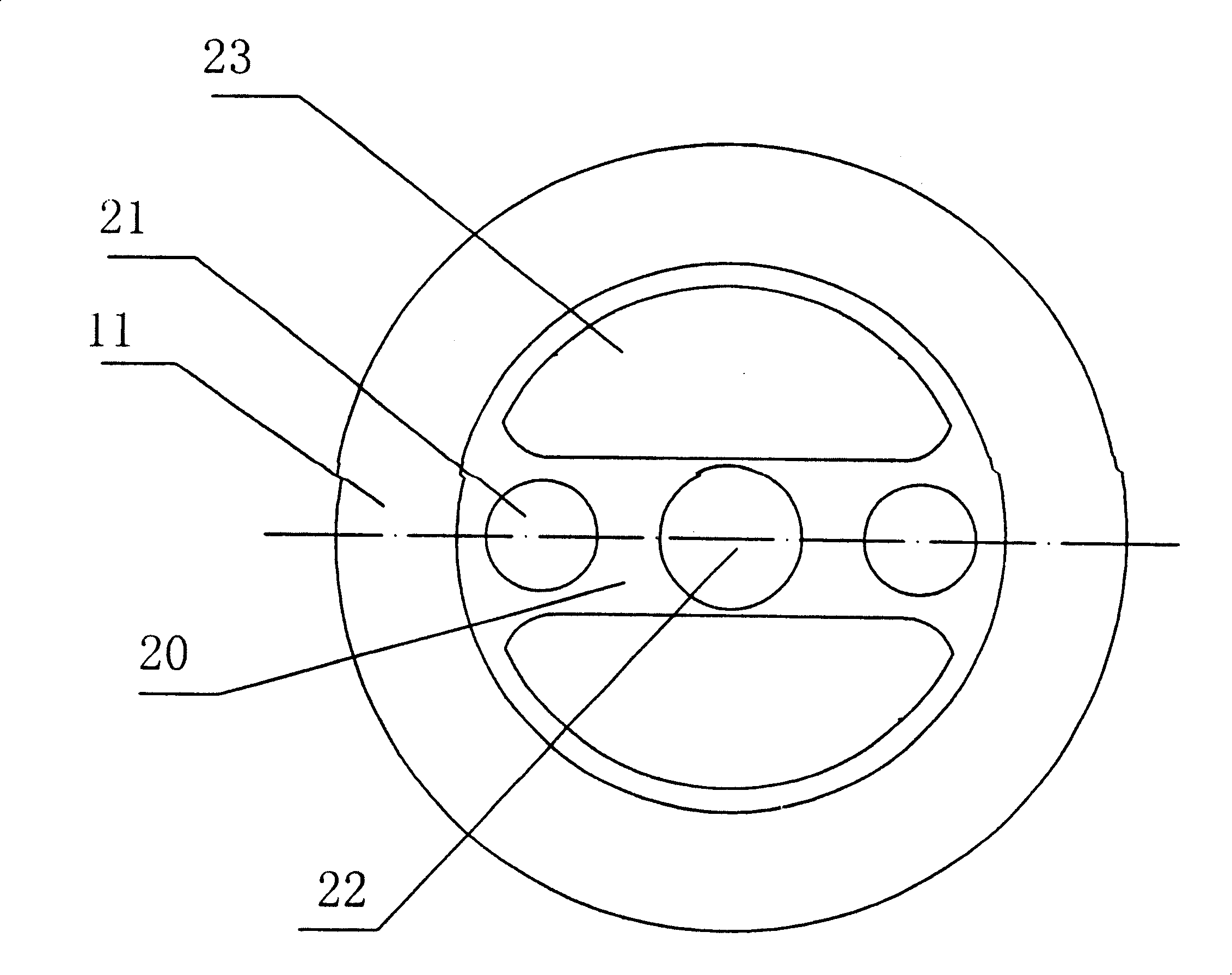

[0010] gas burners such as figure 1 As shown: it is composed of primary mixer 1, secondary mixer 7, tertiary mixer 11, diverter diffuser 15, and mesh cover 16; gas inlet hole 2 and air inlet are made on primary mixer 1 Hole 4, in the lower part of the center, make the gas injection hole 3, and communicate with the gas inlet hole, make the primary mixing chamber 5, and communicate with the air inlet hole in the upper part of the center place, and the air inlet hole can be made 5 to 6, the secondary mixer 7 is made from the lower part of the cylindrical cavity body 6 and transitions upward to the upper part of the curved conical cavity body 8, and the inner cavity constitutes the secondary mixing chamber 9; the tertiary mixer 11 is made of Become the lower cylindrical cavity body 10, transition upwards to the cavity horn body 12, and its inner cavity constitutes a three-stage mixing chamber 13, and a mounting member 20 for installing a primary mixer is made at the bottom port of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap