Fusing agent and temperature fuse containing the same

A technology of thermal fuse and flux, applied in emergency protection devices, circuits, electrical components, etc., can solve the problems of affecting the appearance of thermal fuse, failure to produce flux, flux bubbles, etc., to improve fusing performance and eliminate corrosion. , the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

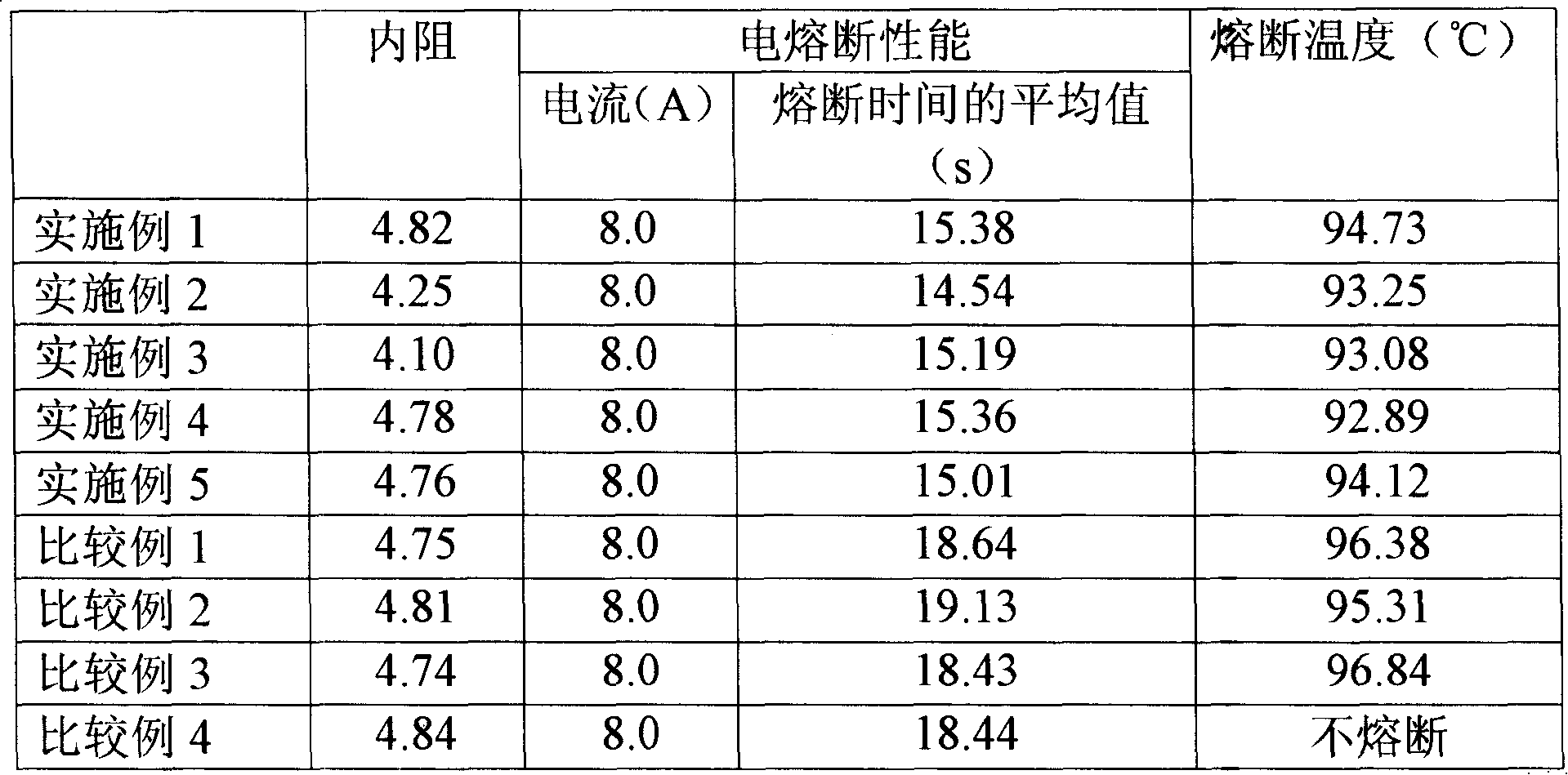

Embodiment 1

[0026] The flux of the present invention is prepared according to the following process: Weigh 6g stearic acid into 10g n-butanol, put it in a thermostat at 120°C until it dissolves, then add 40g ordinary rosin, stir and mix evenly, and put it into the heating furnace Heat it in the medium until it boils, take it out and add 1 g of glacial acetic acid until it cools to room temperature, spot the above flux on the cover film with a dispenser, and ultrasonically weld it to form.

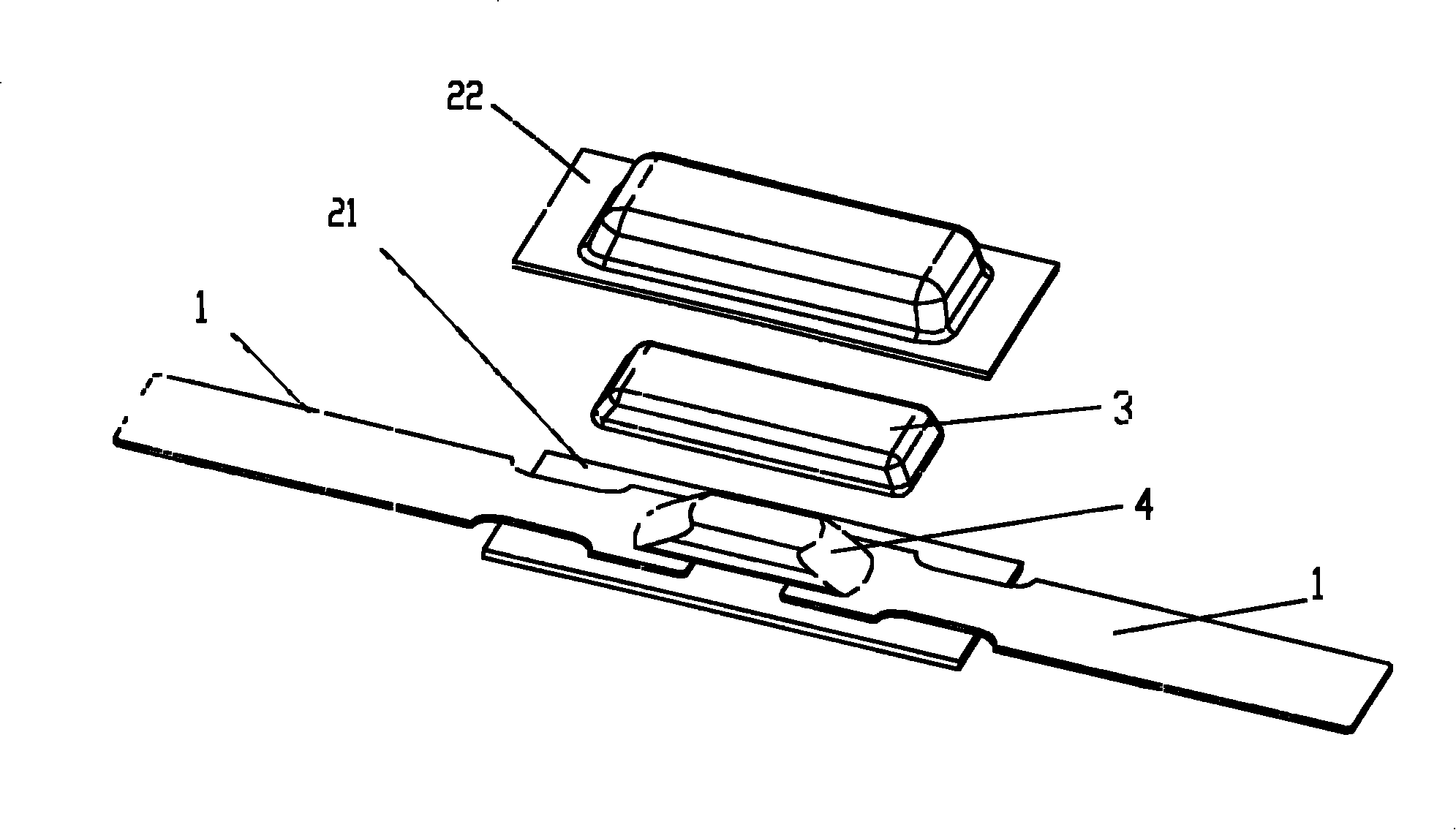

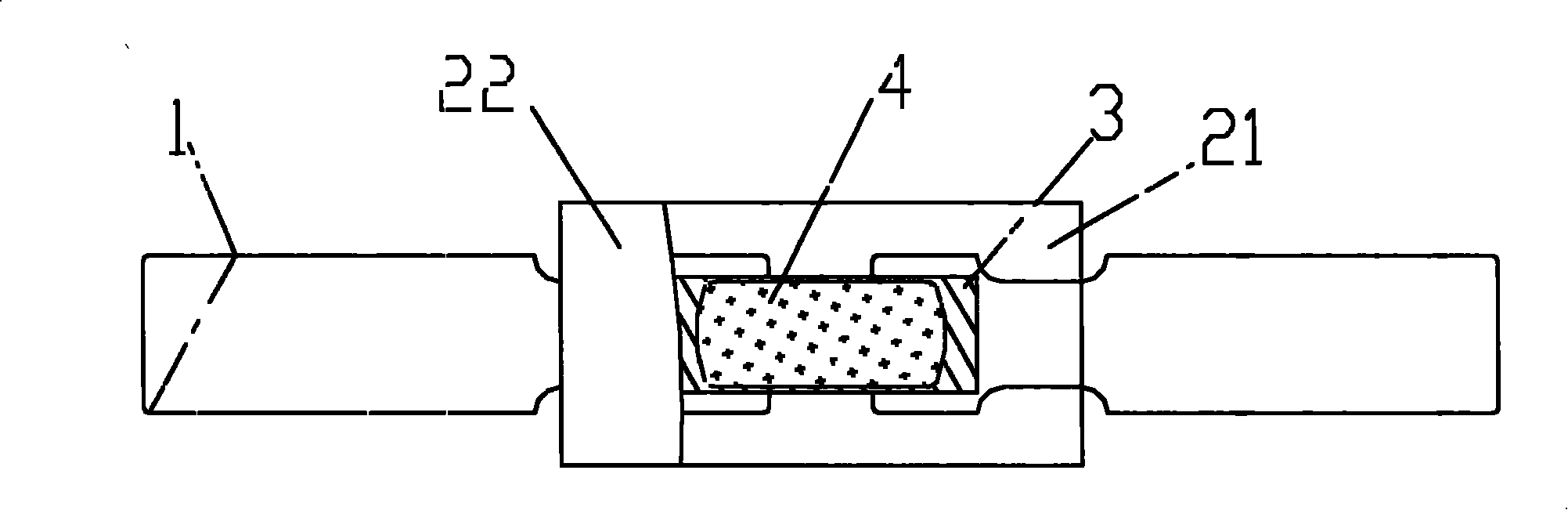

[0027] The cylindrical first alloy wire is molded in a mold to form a low melting point alloy wire (4). The cylindrical first alloy wire has a diameter of 0.4mm and the main components are In, Sn, Bi; the molded low melting point alloy wire The cross-sectional area is 0.126mm 2 .

[0028] According to the components of the thermal fuse, the thermal fuse is prepared and packaged.

Embodiment 2

[0030] Weigh 6.5g stearic acid into 10g n-butanol, put it in a thermostat at 120°C until it dissolves, then add 30g ordinary rosin, stir and mix evenly, put it in a heating furnace and heat it until it boils, take it out and add 1g The glacial acetic acid was cooled to room temperature until it was cooled to room temperature.

[0031] The cylindrical first alloy wire is molded in a mold to form a low melting point alloy wire (4). The present invention uses a cylindrical first alloy wire with a diameter of 0.5 mm and main components of In, Sn, and Bi; the molded low melting point alloy wire The cross-sectional area of the alloy wire is 0.196mm 2 .

Embodiment 3

[0033] Weigh 7g stearic acid into 10g n-butanol, put it in a thermostat at 120℃ until it dissolves, then add 30g ordinary rosin, stir and mix evenly, put it in a heating furnace and heat it until boiling, take it out and add 1g ice Acetic acid until it is cooled to room temperature, and other preparation processes are the same as in Example 1. After placing the flux in the air for 4 days, it was made into a thermal fuse to test its performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com