Mask read-only memory and its manufacturing method

A mask read-only, memory technology, applied in the field of memory, can solve the problems of reduced readout speed, difficulty in proportional reduction, etc., and achieve the effect of small bit line spacing, improved readout speed, and small bit line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The photolithography method of the present invention that can improve the pattern quality will be further described in detail below.

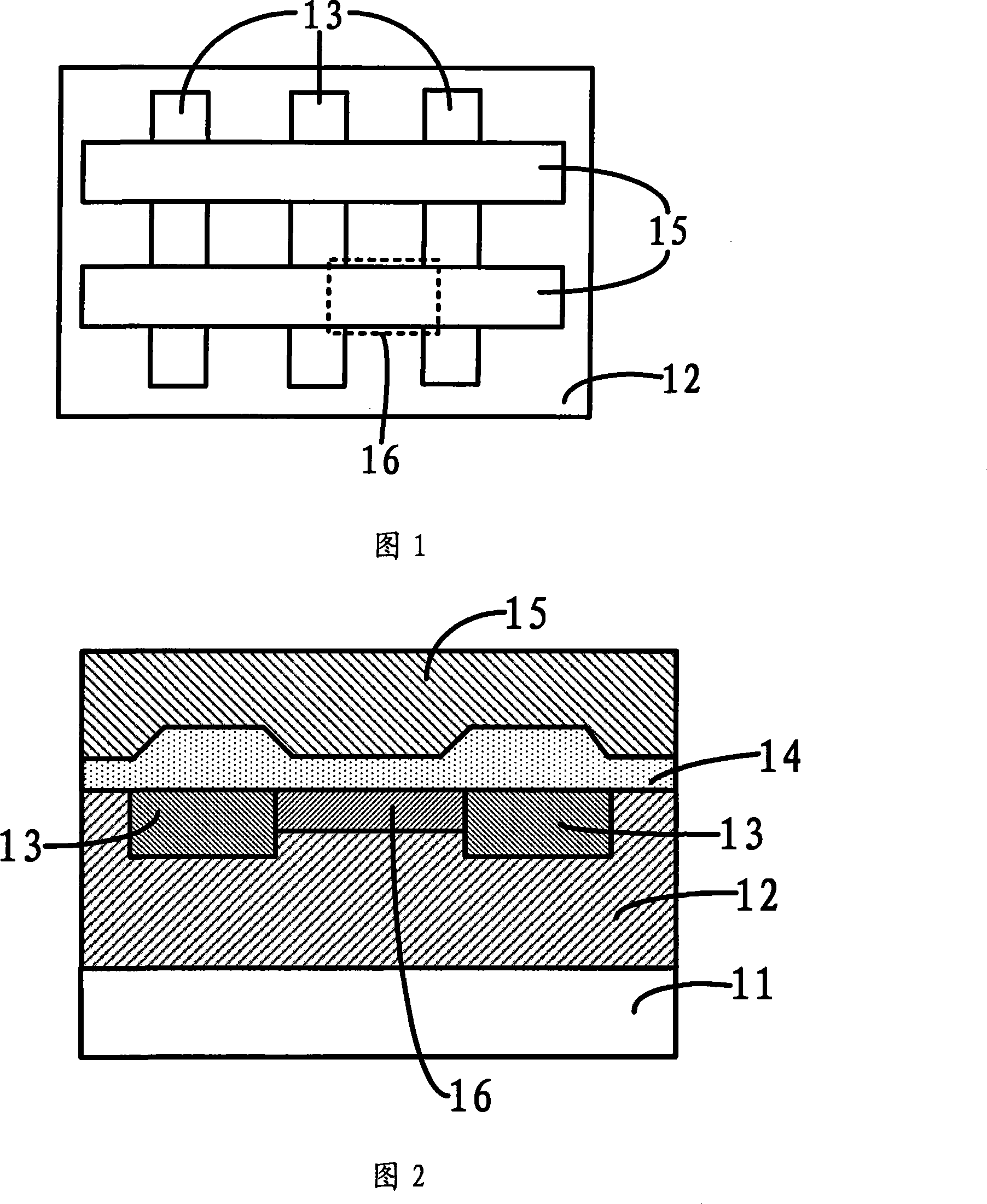

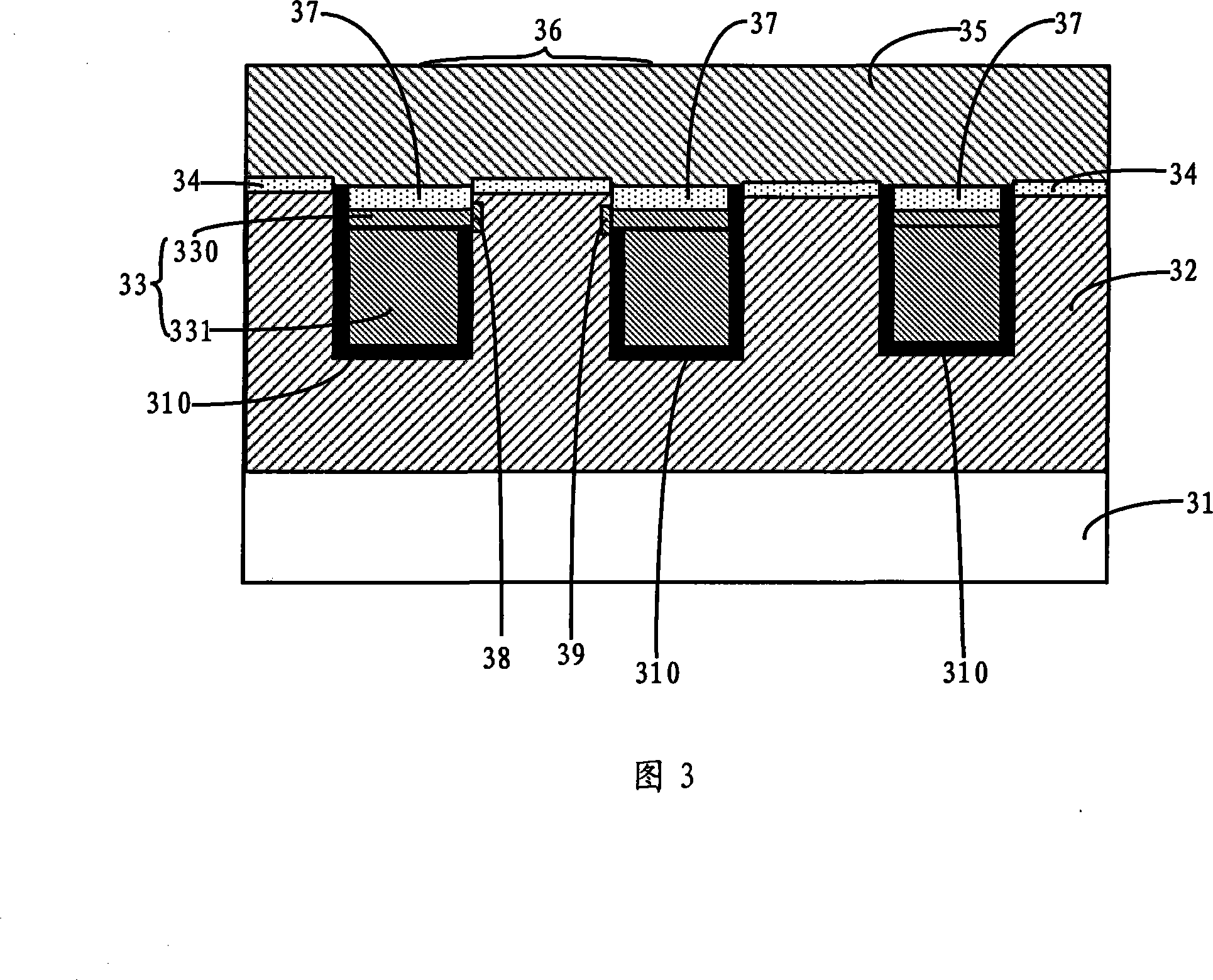

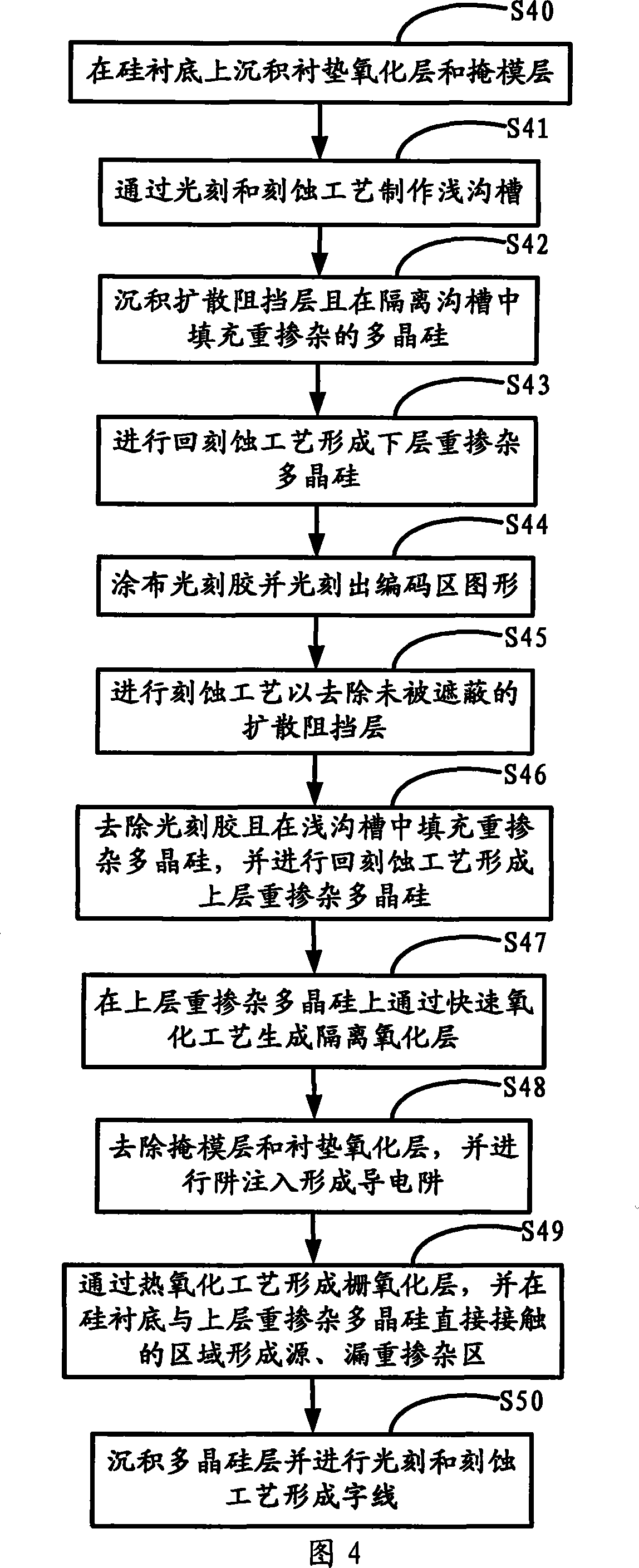

[0028] Referring to FIG. 3, it shows a cross-sectional view of the first embodiment of the mask ROM of the present invention. As shown in the figure, the mask ROM is fabricated in a conductive well 32 on a silicon substrate 31, which includes A plurality of bit lines 33 and word lines 35 arranged in parallel, the plurality of word lines 35 are vertically arranged on the bit lines 33 (the arrangement structure can be referred to FIG. 1 ), the mask read-only memory There are a plurality of coding regions 36, the coding regions 36 cover the word line 35 between the bit lines 33 and the local area adjacent to the bit line 33, there is a gate oxide layer 34 between the word line 35 and the silicon substrate 31, the A shallow trench is opened in the conductive well 32 for the bit line 33, and a diffusion barrier layer 310 is deposited on the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com