Apparatus and method for gasification of refuse and hyperthermia melt processing of flying ash

A high-temperature melting and processing device technology, which is applied in the field of waste gasification and fly ash high-temperature melting integrated processing devices, can solve the problems of heavy metals and dioxins exceeding the standard, and achieve low operating costs, high combustion heat intensity, and slag collection rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

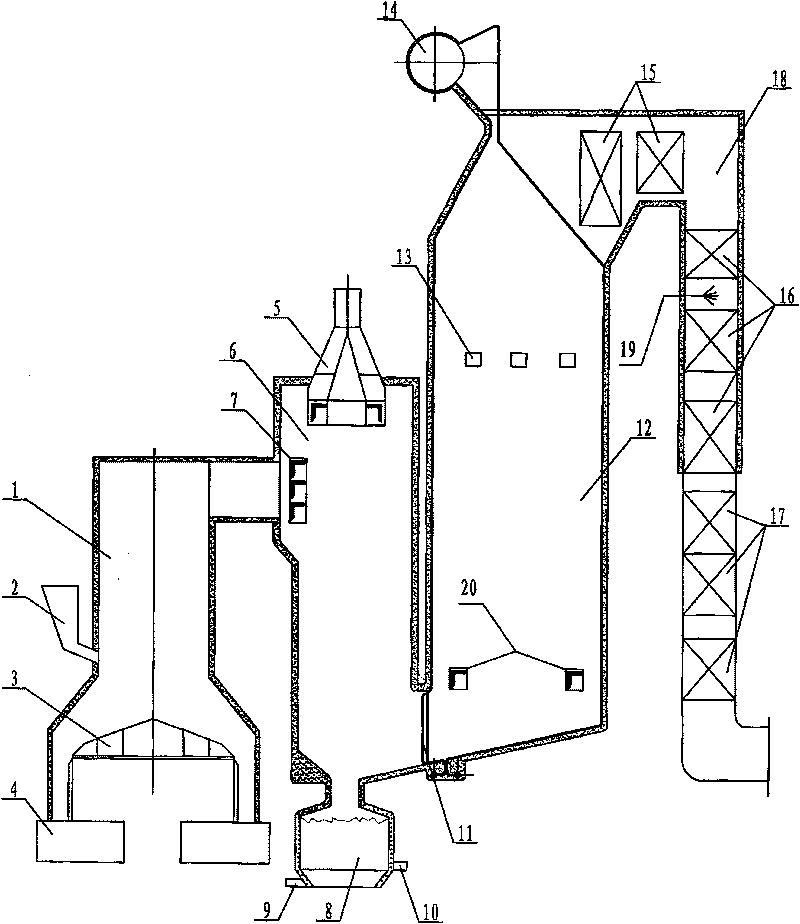

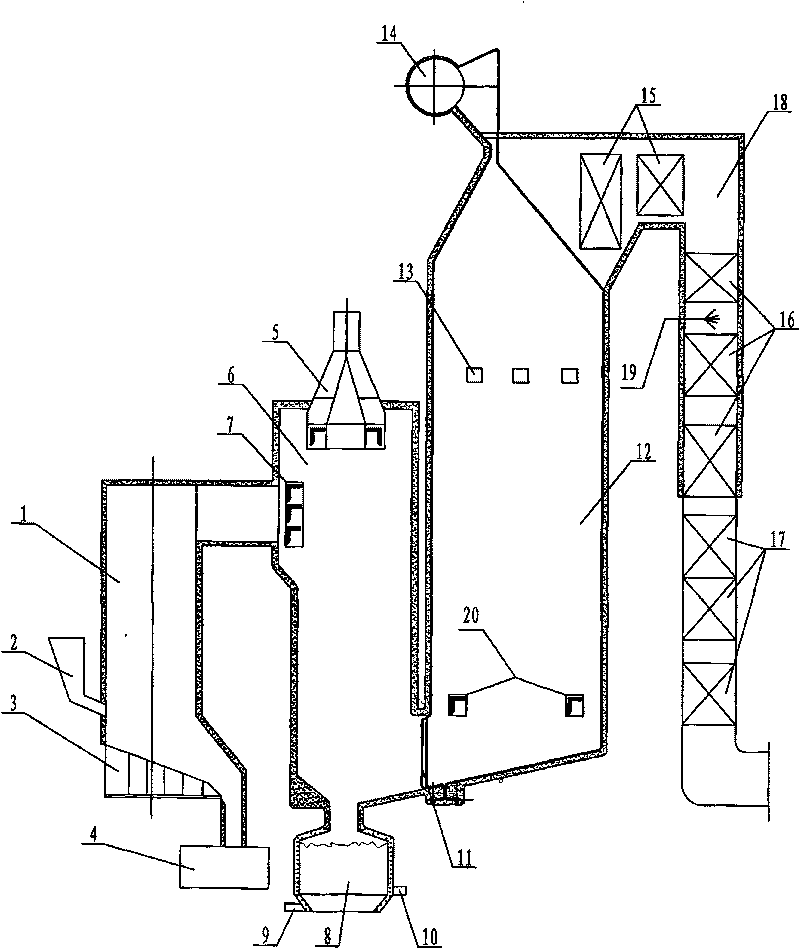

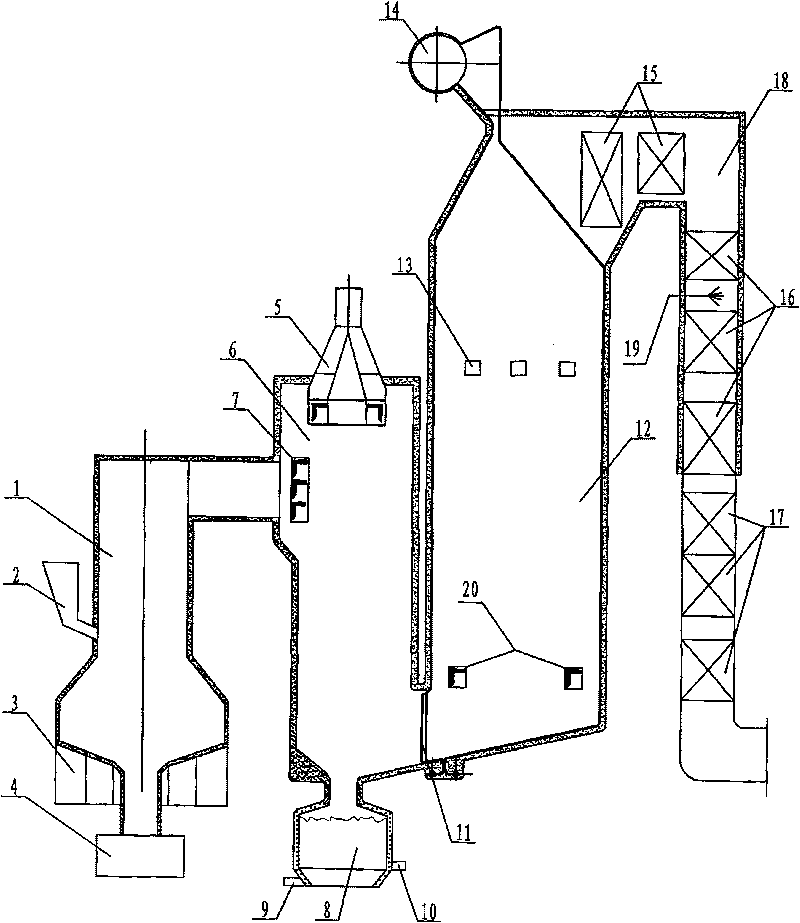

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment consists of a fluidized bed gasifier 1, a feeder 2, an air distributor 3, a drum slag cooler 4, a burner 5, a cyclone furnace 6, a slag pool 8, a water wall 11, The burnout chamber 12, the spout 13, the steam drum 14, the superheater 15, the economizer 16, the air preheater 17, the flue 18 and the rotating secondary tuyere 20, the steam drum 14 is arranged on the top of the burnout chamber 12, A feeder 2 is provided on the side wall of the fluidized bed gasification furnace 1, and an air distribution plate 3 is provided at the lower part of the inner chamber of the fluidized bed gasification furnace 1, and a drum slag cooler 4 is provided at the lower part of the air distribution board 3, The drum slag cooler 4 has the function of separating fine sand and large non-combustibles. The upper part of the fluidized bed gasifier 1 communicates with the cyclone furnace 6. The top of th...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is: in this embodiment, a secondary air nozzle 7 is added at the outlet of the fluidized bed gasification furnace 1, and the secondary air nozzle 7 is arranged on the inner wall of the cyclone furnace 6 upper part. Air is sprayed into the cyclone furnace 6 through the secondary air nozzle 7 to provide the required air for combustible gas combustion from the fluidized bed gasification furnace 1, and the temperature inside the cyclone furnace 6 is 1400-1650 °C. In this embodiment, the cyclone furnace 6 is an oxidative atmosphere, and heavy metal oxides cannot be reduced to metals. The cyclone furnace 6 is a simple fly ash melting furnace, and metals are not recovered. At this time, the rotating secondary air outlet at the bottom of the burnout chamber 12 20 stop the air supply. Other compositions and connections are the same a...

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment one is: this embodiment also increases the dioxin blocker spout 19, and the dioxin blocker spout 19 is arranged in the economizer 16 400- In the 600°C interval, spray dioxin blocker (NH 3 , methylamine, etc.), can block the re-synthesis of dioxins, and further control the formation of dioxins at the tail. This is because in the temperature range of 200-500°C at the tail, the decomposed dioxin fragments (small molecules) are exposed to divalent copper ions (Cu 2+ ) will be re-synthesized to generate a small amount of dioxins. In order to prevent this reaction from proceeding smoothly, injection of dioxin blockers has achieved the purpose of further controlling dioxins. Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com