Novel heating method and electric heater thereof

An electric heater and a new type of technology, applied in the field of electric heaters and heating, can solve the problems of power consumption, many processing procedures, and large power consumption, and achieve the effects of saving water, good heat dissipation, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

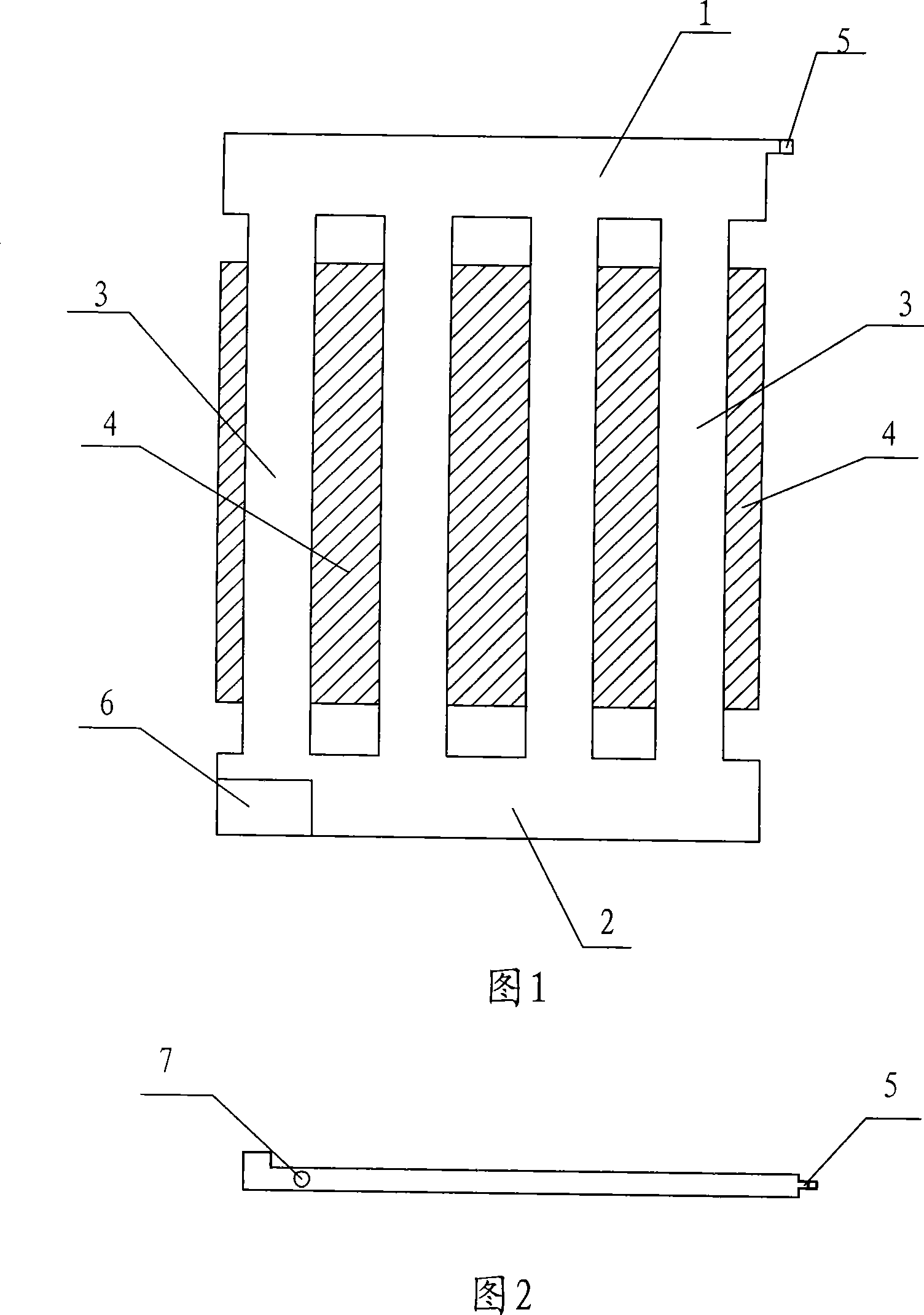

[0018] An electric heater is provided with an upper header, a radiating pipe, and a lower header in sequence from top to bottom, including a water injection port attached thereto, an exhaust valve, and a heating box, wherein the water injection port is arranged on the upper header On the top of the box, the exhaust valve is set at one end of the upper header, the heat sink is airtightly connected with the upper and lower headers, and the heating box is fixed in the cavity of the lower header, including a closed shell and a heating and temperature control structure.

[0019] A heat dissipation plate is arranged on the outside of the heat dissipation fin to enhance the heat dissipation effect, so as to better achieve the purpose of heat dissipation.

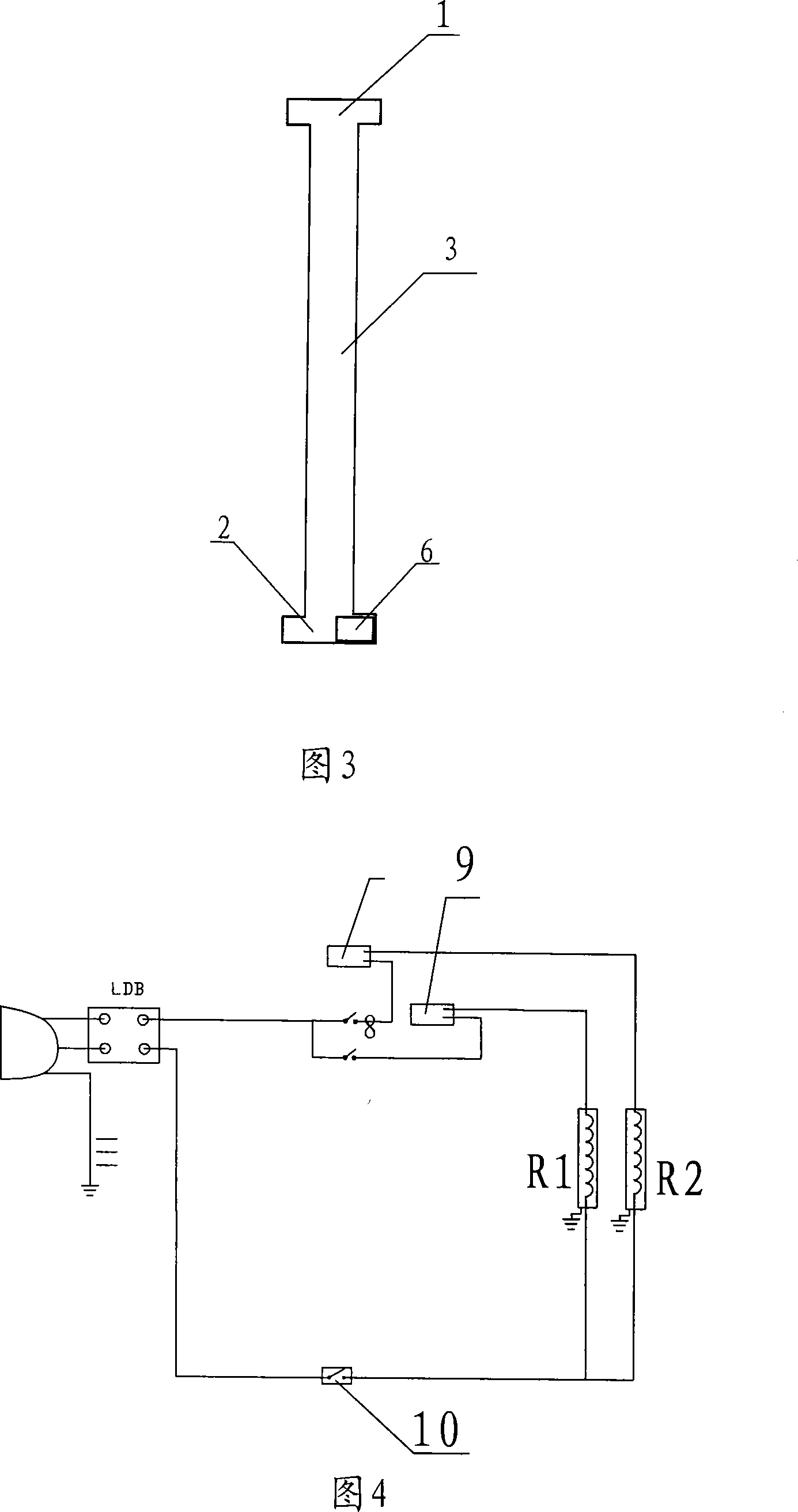

[0020] The heating and temperature control structure includes a heating rod, a temperature controller, a thermal protector, a leakage protector and a wire. The thermal protector, the temperature controller and the heating rod are co...

Embodiment 2

[0028] An electric heater, its principle is: inject an appropriate amount of water into a closed container, and then extract part of the air in the container according to the following formula, so that the pressure in the container reaches a certain low pressure value:

[0029] t=100.00+0.0367(p-760)-0.000023(p-760) 2

[0030] Among them, t is the preset boiling point of water, the unit is ℃; p is the air pressure value that needs to be set inside the airtight chamber, the unit is mmHg (1 atmosphere = 760mmHg, 1mmHg = 133.3Pa); then the water is heated, due to the extraction of The air has a set boiling point, and when the water temperature reaches the set boiling point, the water will boil and produce water vapor.

[0031] This electric heater is provided with an upper header 1, a cooling pipe 3 and a lower header 2 from top to bottom, and also includes a water injection port 7 attached thereto, an exhaust valve 5, and a heating box 6, wherein the water injection port 7 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com