Device and method for focusing and leveling based on microlens array

A micro-lens array, focusing and leveling technology, applied in the field of optical measurement, can solve the problems of difficult to improve single-point measurement accuracy, reduce system measurement accuracy, and high requirements for light source stability, so as to improve measurement accuracy and overall system adaptability. , The effect of reducing the requirements of light source stability and reducing the difficulty of optical design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with the drawings.

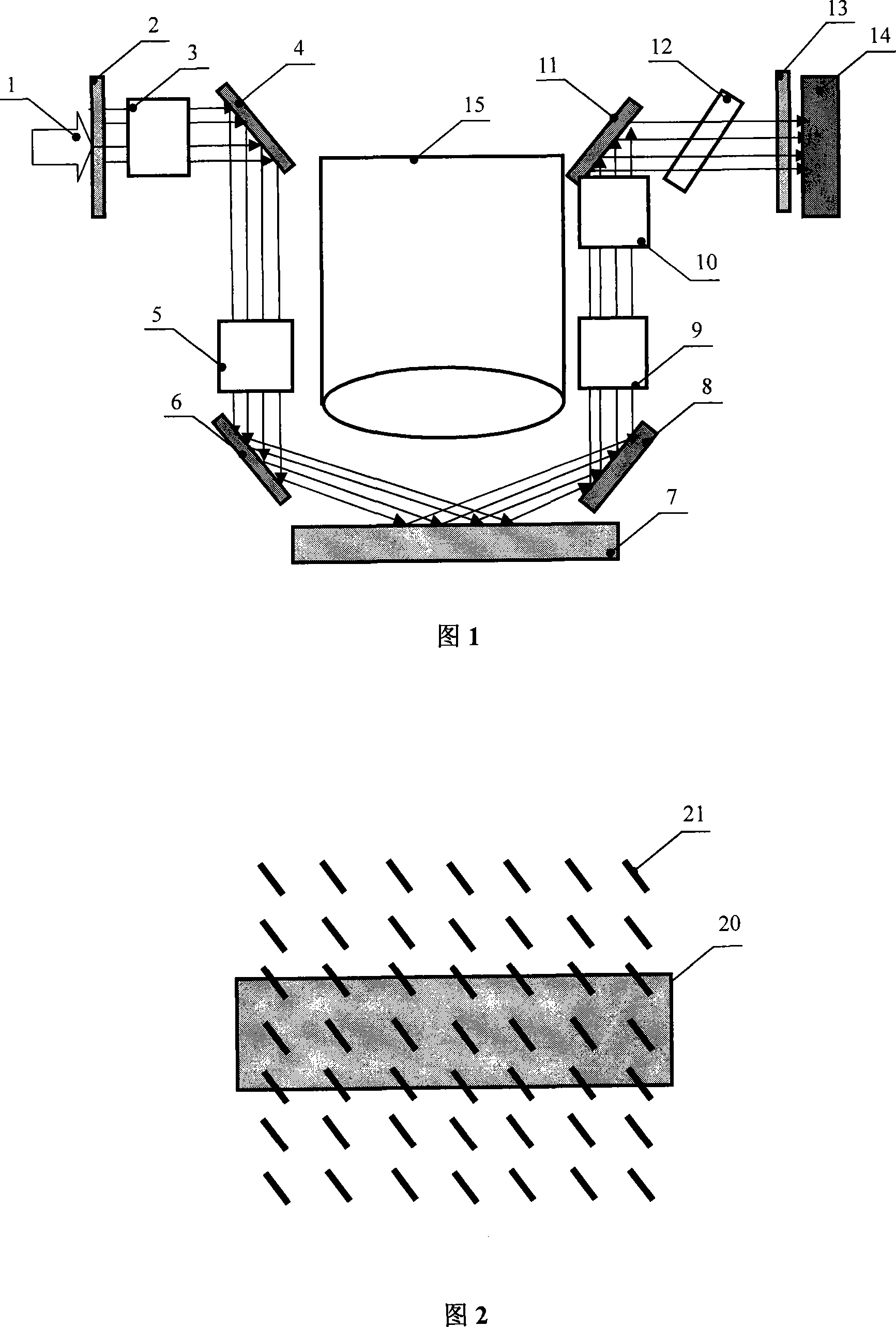

[0037] As shown in FIG. 3, it is a schematic diagram of the structure of the focusing and leveling system of the lithography machine of the present invention. The optical system of the focusing and leveling device of the present invention includes two large modules, namely a transmitting module and a receiving module.

[0038] Hereinafter, each component module of the optical system of the present invention will be described one by one with reference to FIG. 3.

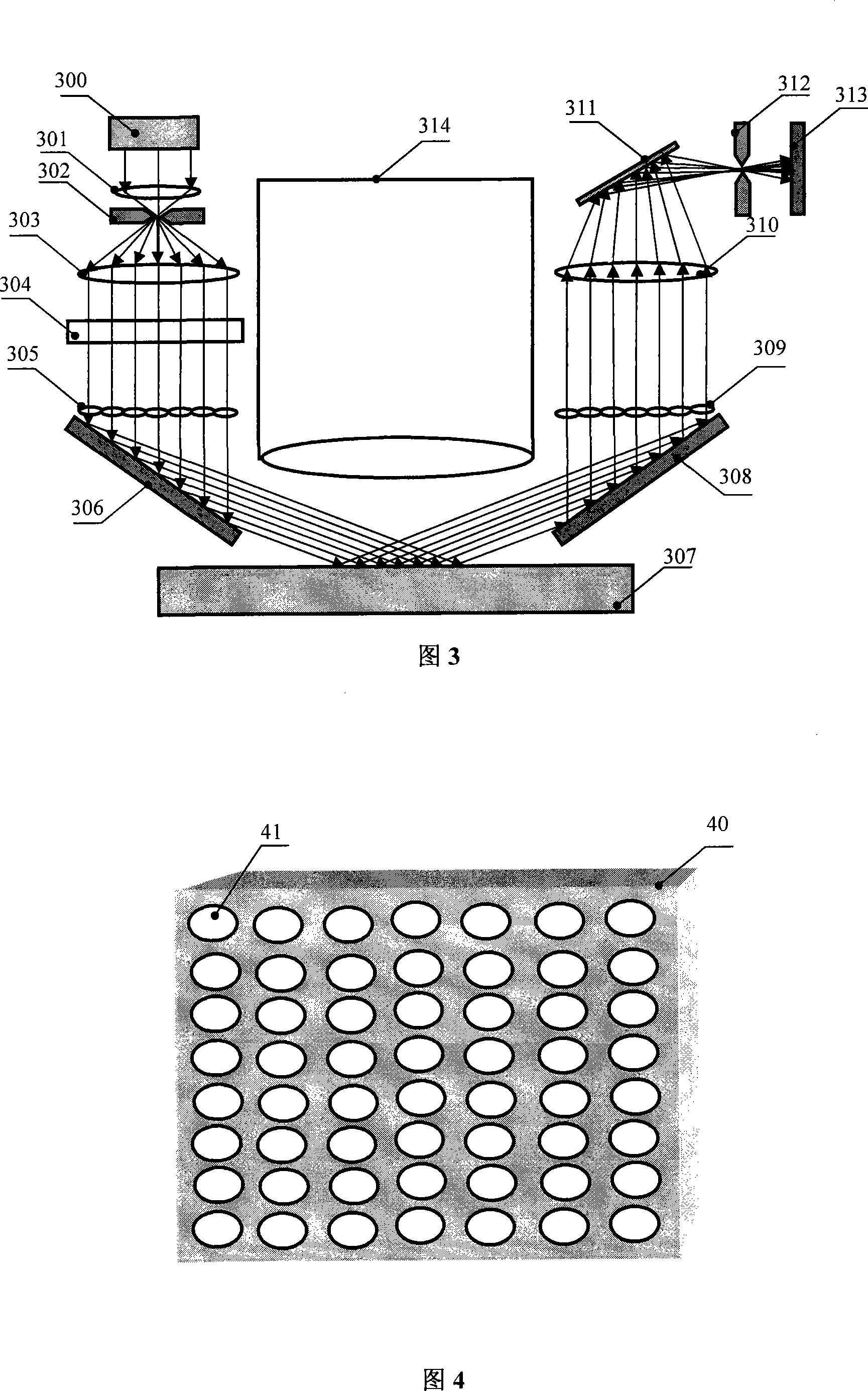

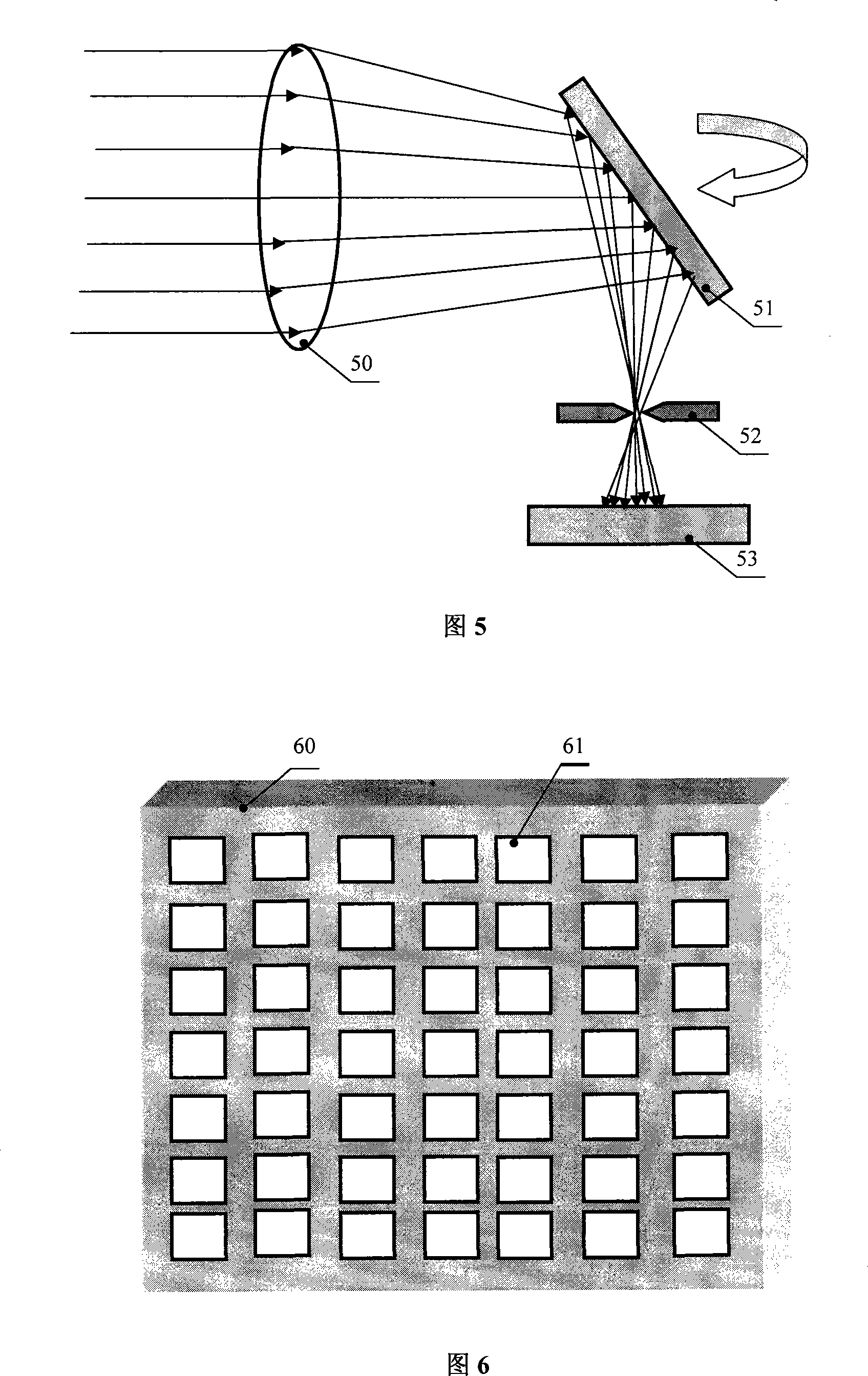

[0039] The light source 300 is reshaped, focused by the focusing lens 301 and incident on the pinhole filter 302, and then expanded by the beam expander lens 303. The beam-expanded parallel light is controlled by the optimizing entrance pupil device 304 to control the amount of light passing. After 304, the micro lens array 305 is used to align the corresponding parallel light beams, and the light passes through the micro lens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com