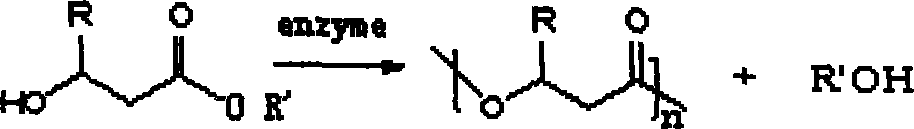

Method for preparing polyesters by enzyme catalysis

A technology for catalytic preparation and polyester, applied in fermentation and other directions, can solve problems such as limited application, and achieve the effect of easy operation and good industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

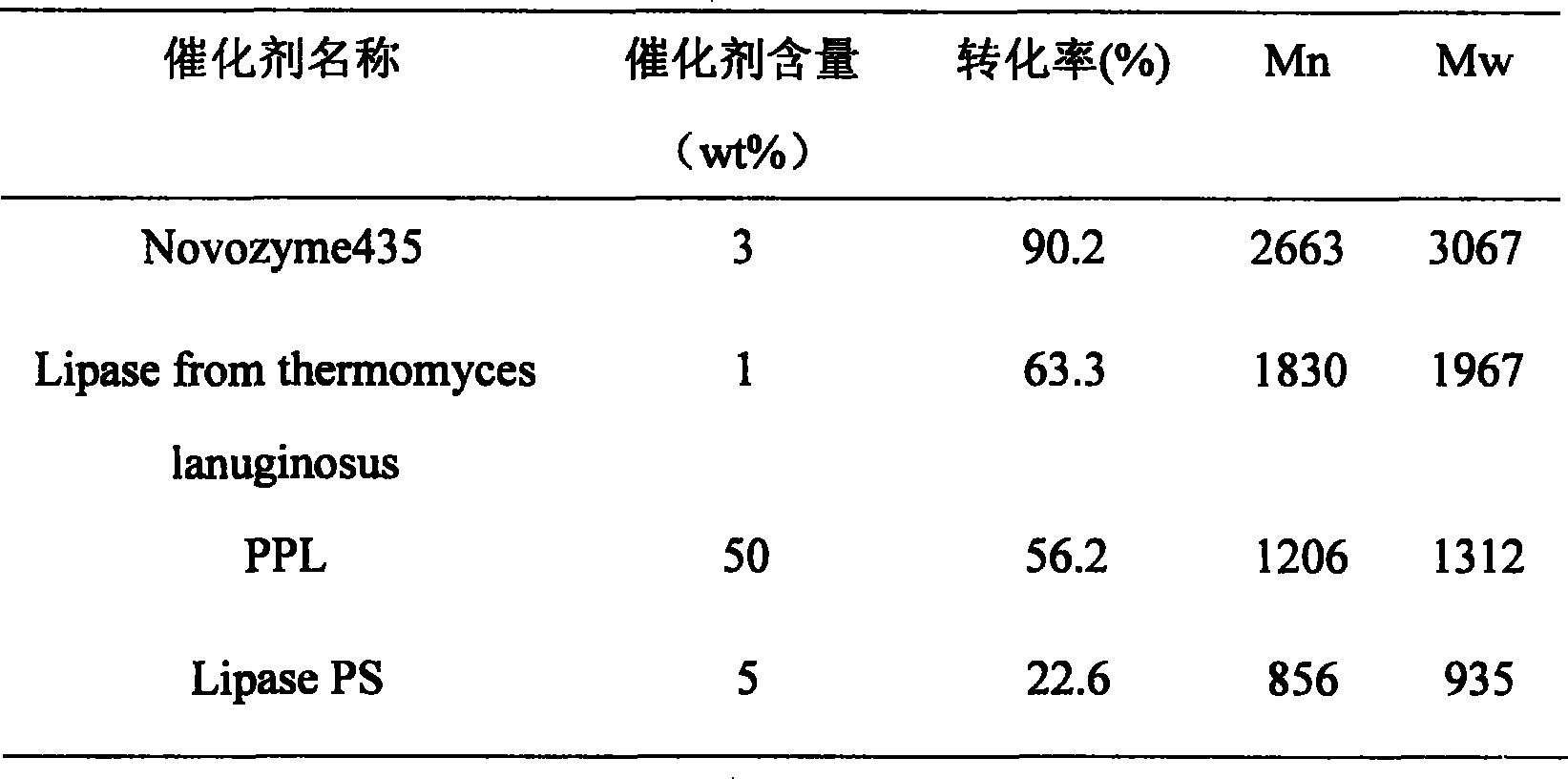

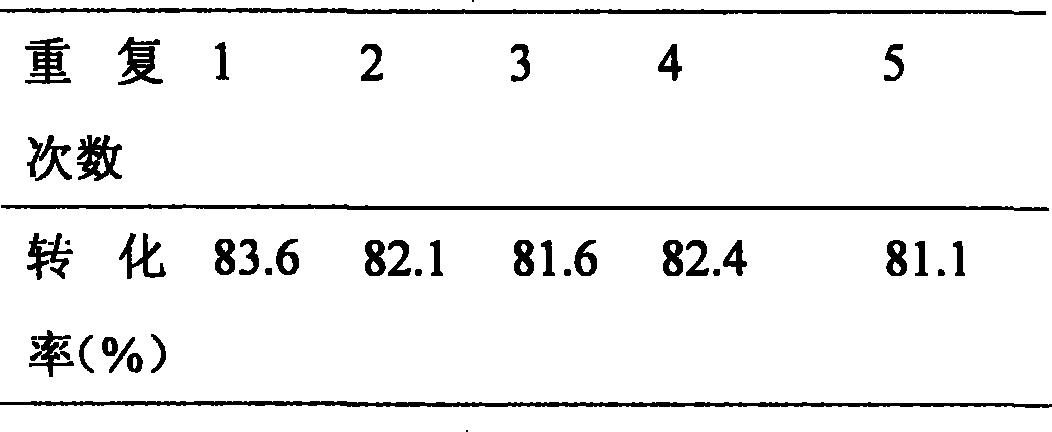

Embodiment 1

[0019] 3.0 g of β-hydroxypropionate and different biological enzymes at a certain concentration were reacted at 50° C. under a reduced pressure of 70 mmHg to obtain a white polyhydroxypropionate solid product.

[0020] Detection method: Use gas chromatography Agilent6890 for monomer conversion, DM-5MS column, nitrogen as carrier gas, flow rate 3.0ml / min. Programmed temperature: initial temperature 60°C to 280°C (20°C / min), keep for 10min. Toluene as an internal standard.

[0021] Polymer molecular weight is detected by GPC: Waters HPLC 2695 is equipped with 510 pumps, 717 autosamplers, and 2414 refraction detectors, and the chromatographic columns are styragel@HT3, styragel@HT5 and styragel@HT6E Tolene series columns; chloroform (HPLC-grade ) as eluent, flow rate 1.0mL / min. Narrowly distributed polystyrene was purchased from Polymer Laboratories with molecular weight from 500 to 3,000,000 as a standard. Polymer molecular weight was calculated using waters authorized software. ...

Embodiment 2

[0025] 3.0 g of β-hydroxypropionate and 30 mg of biological enzyme (Novozyme435) were reacted under reduced pressure at 30° C. to obtain a white polyhydroxy ester solid product. Gas chromatography detects that its conversion rate is 66.2%;

Embodiment 3

[0027] 3.0 g of β-hydroxypropionate and 30 mg of biological enzyme (Novozyme435) were reacted under reduced pressure at 70° C. to obtain a white polyhydroxy ester solid product. Gas chromatography detects that its conversion rate is 59.8%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com